In our daily lives, comfort is a priority. In our jobs and businesses, flexibility and efficiency play a crucial role. Together, the effect our lives have on the natural environment must be contemplated at every situation. Proven engineering integrated energy solutions that are providing this are cogeneration and tri-generation systems. They incorporate heat generation, cooling energy generation and electric power production. The two technologies are interesting steps that different entities are taking to combat greenhouse gas emissions and enhance energy efficiency. For a long time, cogeneration has been the sole point of discussion and most industries have adopted its transformative effect. Time has come now that industries are also adopting tri-generation extensively for power plant design. Here is a brief coverage of the basics and applications of these systems.

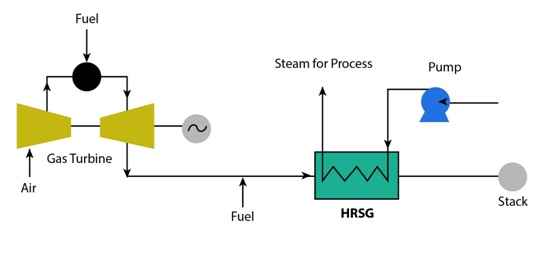

Operating Principle of Cogeneration

Cogeneration technology traces its origin to the USA and Europe in the 1880s when steam turbine generators and coal-fired boilers helped industries produce electricity. Cogeneration is the on-site generation and use of two different forms of energy simultaneously from one source. The most popular scenario of this involves electrical power and heat, which is popularly called CHP or Combined Heat and Power. Power is produced and the resulting heat is recovered for use in the production of hot air, hot water or steam.

Fig 1: Cogeneration Concept

Cogeneration can also take the form of Combined Cold and Power (CCP), whereby cooling energy is generated, and the resulting heat is used to produce electrical power or electrical power is generated and the residual heat is used in an absorption chiller to produce cooling.Operating Principle of Tri-Generation

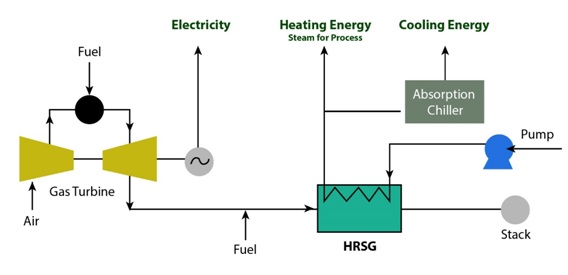

Tri-generation is the simultaneous production of heating energy, electrical power and cooling energy. It is the extension of cogeneration principle with the addition of the cooling. Many establishments need cooling alongside electric power and heat, hence the growing popularity of tri-generation energy plants. The figure below demonstrates this process.

Fig 1: Tri-Generation Process

Benefits of These Processes

Cogeneration and tri-generation provide numerous advantages. Owing to the recovered heat losses, cogeneration can have an overall efficiency of up to 90%. The electrical efficiency in the production of power alone has an efficiency of around 35%. While this is not different from the efficiency of a conventional energy plant, the fact that cogeneration recovers heat makes all the difference. This massive overall efficiency of cogeneration minimizes exploitation of primary resources. Fuel savings of up to 40% as compared to standalone production heat and power is the secret. The advantages of the cogeneration system are even more attractive if you consider the effects of fuel savings on the amount of greenhouse gases emitted into the atmosphere. Experts have put the amount of CO 2 emissions reduced at 200 million tons in Europe alone. Cogeneration is an excellent way to decentralize power generation. Apart from reducing energy transmission losses, this setup is a welcome innovation because it has created many job opportunities. For tri-generation, the benefits are similar, except for the fact that they are more significant. Addition of cooling means that the system can be used all over the year. The payback period is shorter, which is quite something from an economic point of view. As the demand for different forms of energy varies throughout the day, a co-generation setup can be ideal energy management solution. The public grid takes control of electricity production. A boiler can manage the variations that come with heating needs. To cater for the cooling needs of users, a complementary cooling unit can also be installed. Buildings in most places have rather predictable energy needs. Summers are associated with a high cooling demand while winter means a higher heating demand. The tri-generation system can be designed to focus on heat production or cooling production depending on the prevailing season.

TIAC: What Is Its Connection to Cogeneration/Tri-Generation?

Cogeneration and tri-generation systems that use combustion gas turbines and are located in hot climates can achieve even higher reduction of carbon dioxide emissions and improvement of energy efficiency by incorporating Turbine Inlet Air Cooling (TIAC). TIAC is a worthy investment because it boosts the power output and operates with higher efficiency. Here are some benefits of TIAC for plant design in summary:

- Higher power output at a reduced cost

- Maximization of the gas turbine utilization and benefit

- Reduced operating costs for cogeneration and tri-generation system – less fuel required

- Reduced impact of harsh (hot) weather on plant performance

Clients are Reaping the enfit

Owing to the above benefits, cogeneration and tri-generation systems are ideal integrated energy solutions for public, industrial and business sectors. In the industrial sector, processing companies and factories can achieve better efficiency and profitability with any of these systems. This also applies for wellness complexes, hospitals and universities. Entertainment complexes, shopping malls and hotels are also candidates of cogeneration and tri-generation integration.

Conclusion

We have highlighted the basics, advantages and applications of two interesting technologies, but it is true there can be roadblocks to implementation for some clients. Climate suitability, acceptability by utilities and input by governments are examples of major factors to consider. Considering the rate of growth of cities in many parts of the worlds, it is time to take the sustainability talk further by considering integration of cogeneration and tri-generation systems. With ARANER, cogeneration and tri-generation technologies can be incorporated into the district cooling systems for enhanced energy efficiency and reliability. The most important aspect is that these technologies reduce overreliance on grid power. Even when grid electricity goes out, ARANER’s customized district cooling based on cogeneration/tri-generation are secure and stable. To make the deal even better, the firm is ready to help your facility achieve LEED certification with 75-80% extra efficiency! Talk to our experts for queries or insight about the technologies.