Increasing popular in recent years as many nations try to find ways to meet growing cooling demands is District Cooling (DC), an efficient system featuring a centralized cooling plant which serves a group of buildings. DC owes the rise in its popularity to its proven ability to be as much as 50% more efficient than traditional, decentralized air conditioning units. Encouraging the growth of large-scale District Energy systems has the potential to reduce the electric demands in areas where cooling needs contribute to greater than half of the power consumption. One ideal option for a plant located near a river or the sea is to use the nearby water as a free, natural cooling source. Doing so offers significant benefits:

- Lowers the day-to-day operational costs

- Cuts the use of resources

- Reduces or eliminates the use of potentially harmful chemicals.

Water-cooled systems are already in use all over the world; think about power plants and other industries that use rivers, lakes, or seawater for cooling. They usually have a lower condensation temperature, which enhances the cooling performance. These systems require additional pumps and piping in the form of an influent line to bring cold natural water to the facility and an effluent line to return the water to the river or sea. The influent line must be located to collect and carry water of the optimum temperature, usuallybelow 40 ºC, to the chiller plant to act as a heat-sync for the warmer return water from the District Cooling system.

Overview of River or Seawater District Energy Systems

A District Cooling plant located a reasonable distance from a natural cold-water source, as cold or even colder than the water used in conventional cooling, can use this water as a cooling source. Taking advantage of the natural cooling of water can significantly reduce, even eliminate, the use of chillers and result in a corresponding power savings. A temperature profile is created for the source water to determine the ideal depth for the source water influent pipeline.

The Water Pipeline and Cooling System Components

.jpg?width=414&name=Pipelines%20for%20a%20deep%20water%20source%20District%20Energy%20system%20(1).jpg)

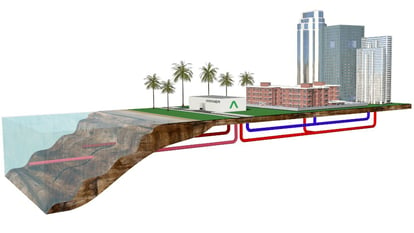

Figure 1: Deep water source pipelines

The location of the influent piping has an impact on the project as an increase in distance increases the cost, making it crucial to locate the pipe inlet accurately. In other words, just deep enough to get the water at the temperature needed year-round. A pipeline is then built to carry the cold source water from that depth to the plant, the pipeline along with any necessary pumps carries the raw source water to the district cooling plant or chilling station. When it reaches the plant or chilling station, the cold water passes through a heat exchanger where the system water rejects heat to the cold source water. The warmer water leaving the heat exchanger travels back to the source via an effluent pipeline. Locating the effluent pipeline a sufficient distance from the influent piping will avoid thermal plumes from the effluent affecting the temperature at the intake. Ideally, the temperature of the water in the effluent pipe and the source water in the area of the discharge should be similar (around +5 ºC) to avoid unwanted ecological and environmental effects.

Sea-water District Cooling Options

Figure 2: Seawater District Energy system

Figure 2: Seawater District Energy system

In most cases, the water may not be cold enough to provide the cooling energy, but seawater can still be used to offset energy costs. In these cases , seawater can be used to precool the system water in a heat exchanger or to directly pass through the chiller condensers. In other cases, the distance necessary to bring water to the facility may be cost-prohibitive, because of length and depth. Water located closer to shore, , can be used to offset the costs of chilling water for DC by reducing the condensing temperature of the chiller. Using a seawater cooled condenser instead of an air-cooled condenser can save 25% or more of the energy used by the chiller. When using a seawater cooled condenser instead of an evaporative cooling tower, it may have additional benefits, such as reduced noise, water demand, and sewage fees typically associated with these towers. Discover the 6 main advantages of using seawater for District Cooling!

River/Sea Water Use Misperception

“Sea/River Water-cooled” systems have historically been perceived as using large quantities of water, which couldn’t be further from the truth . The source water never leaves the piping, never mixes with the system water, and is returned just a few degrees warmer. Many people are under the perception that these systems require additional maintenance than the conventional water cooled/air-cooled counterparts; there are many different variables which determine maintenance needs. The truth is that the difference in maintenance requirements are usually negligible between an air-cooled and a water-cooled system. The treatment necessary with water-cooled systems can be another concern, as many believe it is potentially unsafe and environmentally harsh. The typical treatment of cooling water is the minimum required to keep the pipelines in good condition and return the water in a state similar to its original condition. There are also newer treatment technologies available which require no or minimal chemicals.

Naturally, sea or river water cooled District Energy systems are an ideal solution for facilities located in proximity to a body of water suitable for cooling, whether it be the ocean, a river, or lake. However, in order to determine the proper design of your system, distance to the water source, water temperature, and other variables need to be defined and analyzed. ARANER’s experts can determine how a river or seawater District Cooling system can work for your project. Why invest in a District Energy project? The energy savings potential alone is likely to be worth any additional capital expenditure incurred. DC systems are also 50% more efficient that decentralized air conditioning units. The other benefits, like lower daily operational costs, fewer resources, and the reduction of harmful chemicals like refrigerants, are an added value. Get in touch with ARANER to find out everything you need to know about seawater and river District Cooling systems!