Both new and existing gas turbine power plants for combined-cycle, simple cycle, cogeneration and mechanical drive applications need Turbine Inlet Air Cooling (TIAC) technology for power output maximization and energy efficiency improvement. Without conversance with the natural steps for TIAC design, the process can be challenging and the results disappointing. Consider optimizing the performance of your gas turbine for the plant, by using Araner parameters, as detailed in the eBook.

1. Ambient Conditions

Araner obtains real weather data of the plant, as the first step of the design process. A preliminary study may be done to help determine wet bulb temperature and dry bulb temperature. Design ambient conditions are optimized for the most cost and energy efficient TIAC solution. Araner holds the optimization of the design in high esteem, as this creates a properly designed cooling plant with lower footprint and lower electrical consumption, ending in a more efficient solution. Only an experienced and expert TIAC designer can evaluate the relevant parameters and create a reliable solution. The eBook demonstrates some of the graphs that result from careful analysis.

2. Desired Air Cooling

This is an equally important step because the air entering the turbine must be set at a certain temperature. Every case is different, as these parameters vary from one power station to another:

- Air mass flow at the conditions downstream of the TIAC

- Inlet air dry bulb temperature downstream the TIAC system

The ISO conditions for the gas turbine are 15.0 ºC and 60% relative humidity. This is not to say that TIAC cannot achieve even lower temperatures. However, it is important for correct studies and analyses to be conducted to determine if this would be necessary. That is why we insist on competent team performing this step of the design process as well. As the graph in the eBooks portrays, it would be disastrous to ignore the effect of ambient conditions when designing a gas turbine for a power plant.

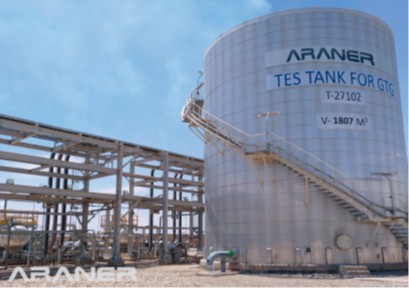

3. Thermal Energy Storage

It is always a serious deliberation on whether a TES tank would be necessary for the system. The goodness with a TESTIAC arrangement is that the facility is able to take advantage of the lower power prices night. It is a simple design, but it yields incredible results. For instance, we are able to reduce chiller plant footprint, as part of the cooling load is hosted by the stratified water tank. For some TIAC systems, TES makes absolute sense, but it does not for others. Such are the details that you need to address because this is a crucial part of the design. Of course, it follows that the electrical tariffs in your area have a bearing on the relevance of this installation. TESTIAC offers a number of benefits for users across the globe, especially those that experience hot climates. The diagrams in the eBook explain this aspect more.

Fig 1: Example of Araner TES Tank

4. Heat Rejection Type

The fourth parameter brings to the fore three options of heat rejection technology offered by Araner. You want to note that the choice of a solution will depend on various factors. For instance, seawater cooled condensation can only be viable if your facility is close to the sea. For facilities that are far away from the sea but close to a river, heat rejection can be based on water-cooled condensation. Sometimes, the plant is not close to either the sea or a river. Restrictions on water consumption are also imposed in some areas. Yet, it is still possible to reject heat reliably. Our air-cooled technology comes in handy. There are also instances where cooling towers or evaporative condensers could be applicable. Get the eBook for more information about these possibilities.

5. Centralized or Individual Plant

Finally, it is necessary to ask whether you want an individual plant for each Gas Turbine or you can install one single centralized plant to cool down the air of every Gas Turbine in the plant. There are reasons we vouch for the centralized plant and you want to sample them in the eBook, as this aspect of the design could affect profitability.

Fig 2: A Centralized Plant

As the power plant owner or operator, you can approximate your case by following four decision levels. Check them out in the eBook. An expert from Araner can take up the matter if you need any help. Contacts are available so you can reach us any time for details on TIAC, TES and many other technologies related to the perfect optimization of gas turbine performance for power plants.