TURBINE INLET AIR COOLING

Boost your power and maximize the gas turbine performance

Turbine Inlet Air Cooling (TIAC) is a group of technologies and techniques whose objective is cooling down the intake air of the Gas Turbine (GT) and ultimately power output augmentation. This technology is widely used in hot climates with high ambient temperatures that usually coincide with on-peak power demand. Since the worldwide energy demand is increasing, energy efficiency and effective asset utilization have become two of the most critical issues in power generation.

With the ARANER’s TIAC System this negative effect is compensated thanks to a turbine inlet temperature decrease. The turbine will have constant inlet air temperature, increasing the power output and maintaining it stable against temperature changes. It creates a direct economic benefit in two ways, increasing the annual average output MW and saving capital cost in comparison to additional turbine installation.

Power output and turbine compressor efficiency are proportional to the inlet air mass flow rate, which decreses with higher temperatures. Furthermore, the electricity consumption peak time coincides with the warmer air temperature during the day.

Watch VideoReduces the inlet air temperature by evaporating a spray of water after the filter stage.

A wetted rigid media where water is distributed throughout the header and where air passes through the wet porous surface.

Based on a refrigeration cycle, in which water is cooled to a low temperature and pumped to a cooling coil installed within the turbine’s filter house.

Uses heat as the energy source, instead of using electricity.

Compression chillers driven by natural gas or diesel.

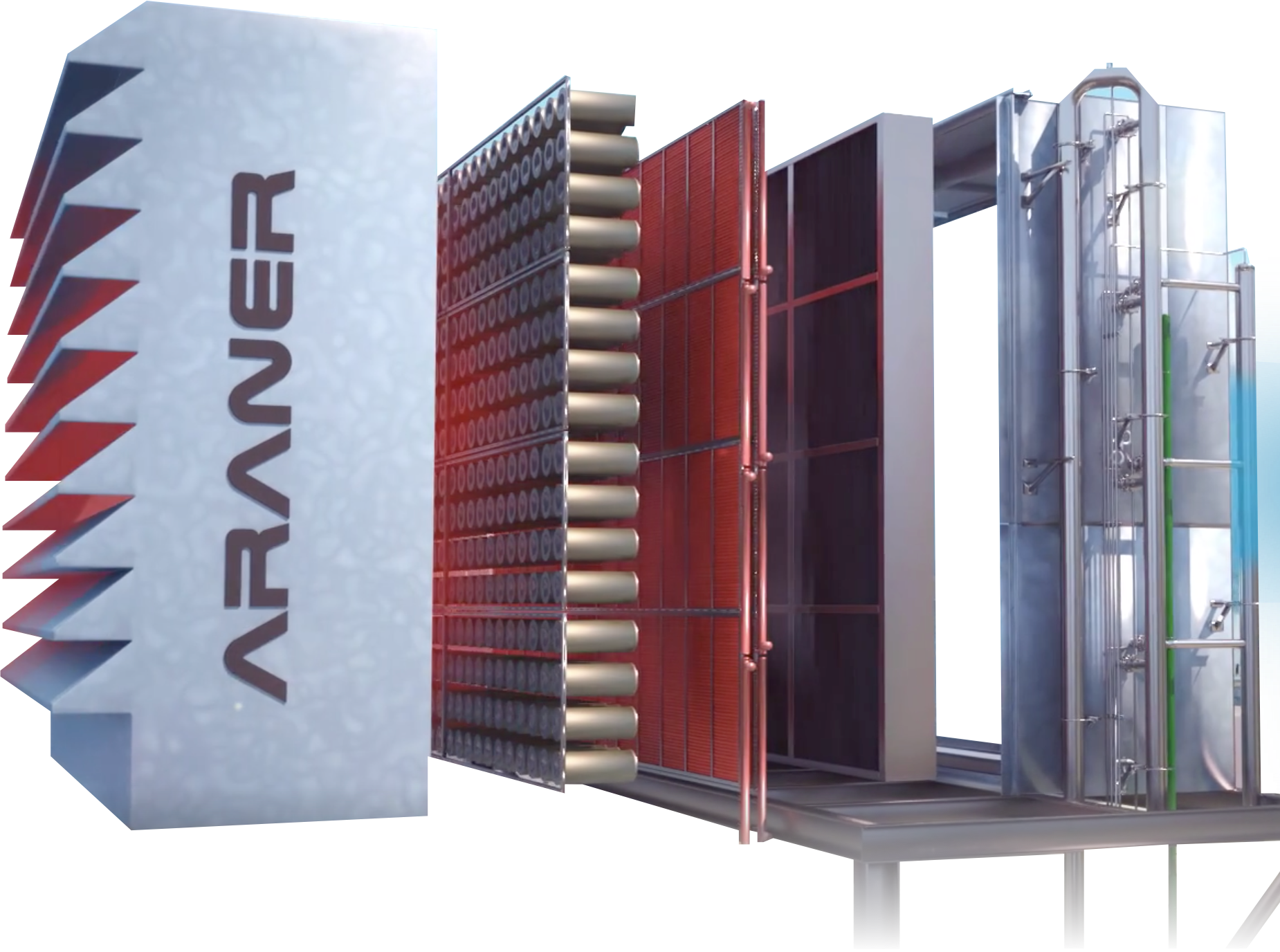

Turbine Inlet Air Cooling system with chillers is the most common, reliable, and up-to-date technology. While other obsolete technologies rely on humidity increase, TIAC with chillers reduces the air temperature by doing a real cooling of the air and reducing the air enthalpy. An inlet air heat exchanger is installed downstream of the filters and the air is cooled by means of a chilled water flow produced in a cooling plant nearby. The air temperature can be selected in the HMI based on the requirements or also the control system can regulate accordingly in the automatic operation mode to achieve the selected air temperature.

A TESTIAC configuration will improve the overall efficiency of the plant. Thermal Energy Storage is very beneficial combined with TIAC for peak power production, when extra power production is required for certain hours per day (typically 3 to 8 hours per day). With a TES Tank the net increase in power output is maximized and the hillers installed capacity required is reduced, reducing also the project cost.

The chilled water stored in the TES tank can be used to provide cooling in facilities that use gas turbines, like a GT Power Plant. TIAC helps increase turbine power output in facilities situated in areas with extreme ambient conditions.

TIAC system can be further improved by using a Thermal Energy Storage Tank. This tank stores the water produced when cooling the turbine’s inlet air does not require the whole chiller system capacity.

TIAC systems are also capable of dry operation with no water consumption in environments where it isn’t available, or also can use seawater cooled chillers when the plant is located close to the sea. This is the most efficient and cost-effective solution in the long-term run for these areas.

Maximum efficiency in simultaneous chilled water PRODUCTION AND CONSUMPTION

Fast system power delivery compared with NEW GAS TURBINE INSTALLATION

AVOID GT OUTPUT FLUCTUATION produced by ambient conditions.

LOWER PRICE per generated megawatt compared with new GT plant.

NO EXTRA auxiliaries’ equipment needed

Recognized GREEN TECHNOLOGY with carbon credits.

Turbine improvement of the HEAT RATE UP TO 5%.

GT POWER OUTPUT INCREASE about 10% to 30%

This strong case study will help you to understand more clearly how TIAC System can optimize the power efficiency on a plant.

A guide to increase your knowledge about turbine cooling and the available technologies.

Solve any doubts through our frequently asked questions or ask for advice

FAQ's about TIACWe create solutions and guarantee success by taking full responsibility of the overall project.