INDUSTRIAL REFRIGERATION

High-level information for developing the most efficient industrial refrigeration systems

Since the early 20th century, Industrial Refrigeration has been used to reduce temperatures, achieve optimal operating conditions, and avoid safety issues.

It is normal to confuse industrial refrigeration and air conditioning. After all, both fields have a shared characteristic- cooling a system. They are integrated with similar components: compressors, heat exchangers, pumps… Normally, the working fluids are water, air, or refrigerant. While much is common about these cooling fields, there are enough differences in the systems, components, design practices, and business methods.

We are in a lively business that provides many technical challenges to consultants. It serves a special role in industry and society. Offering customized systems for the industrial refrigeration market must be a priority for any worthy solutions provider. Each component must be studied in detail because the best results, from our experience, come from the correct synergy between all the components and processes.

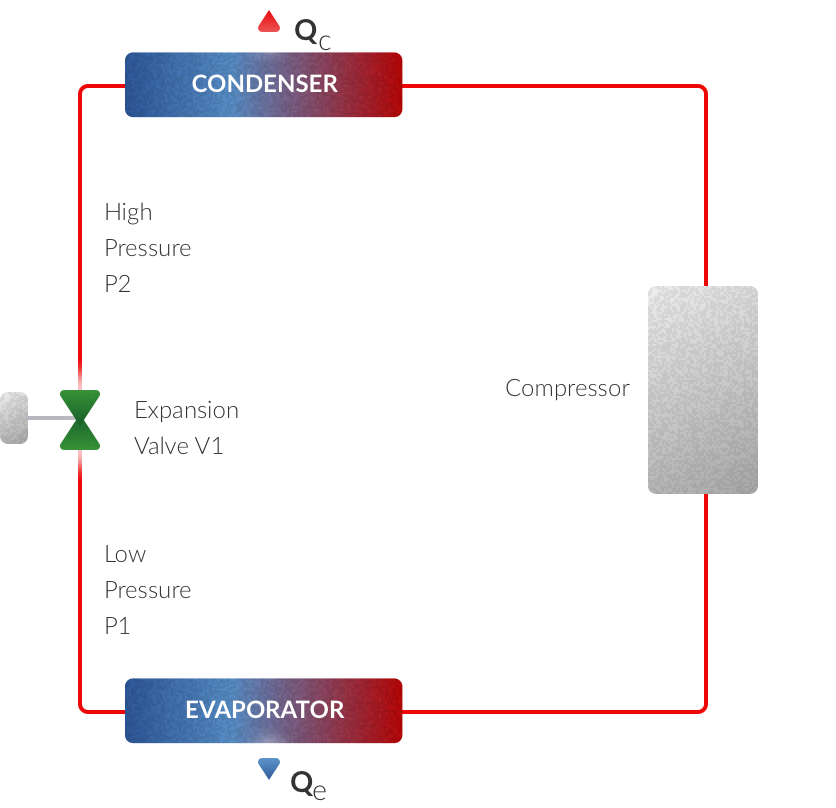

A typical refrigeration system is

composed of four basic components: compressor, condenser, expansion device and evaporator.

The refrigerant in the evaporator has a lower temperature than the cold system, so energy is transferred from the cold system to the refrigerant. The refrigerant changes its phase from liquid to gas, since it is absorbing heat. Then the refrigerant is compressed; the rise of pressure causes the refrigerant temperature to rise above the hot system temperature so the heat can be transferred from the refrigerant to the hot system.

.png)

With the most suitable technologies to go along, we have a wide range of energy-saving solutions that are also some of the most environmentally friendly in the market.

For many industrial refrigeration applications, there is concern about the type of refrigerant to use. It is good to be frank; any refrigerant fits the requirements 100 % for all cooling plants. An ideal refrigerant would need to have it all in terms of material compatibility, chemical stability, performance, non-toxicity, non-flammability, boiling point among other criteria.

True to our commitment to sustainable industrial refrigeration, we can analyze your plant on its merit and suggest a suitable refrigerant. As industrial refrigeration engineers, our designs, products and installations are suitable for the most popular refrigerants. Some of the possible refrigerants for an industrial refrigeration plant are HFC R134a, Ammonia (R717), HFO and Hydrocarbons. For its excellent chemical and thermodynamic properties, water is also a viable industrial refrigerant under special circumstances.

Centralized maintenance of the main equipment of the refrigeration system, carried out by specialized engineers

Improved efficiencies

Wide range of state-of-the-art refrigerants

High efficiency and significant energy savings

Efficient design contributing to Green Building (LEED) certification

Great benefits for spaces with diverse use, as it reduces the peak load of the plant

Find the know-how and all you need about Industrial Refrigeration projects and much more

A guide to refrigeration technologies, based on ARANER’s solutions.

We create solutions and guarantee success by taking full responsibility of the overall project.