DISTRICT HEATING

Efficient heat generation from renewable energy sources

District Heating (DH) is a way of distributing heat generated in a centralized location through a system of insulated pipes for residential and commercial heating requirements, such as space heating and domestic water heating. The heat often comes from a cogeneration plant that is burning fossil fuels or biomass boilers at the same time that CHP system provides electricity. Nevertheless, that is not the only heat generation system: geothermal heating, heat pumps and central solar heating are also used, as well as heat from waste incineration.

Discover why District Heating Technology is used and its evolution over time until reaching the 5th Generation.

District Heating was initially based on steam distribution systems that were established in the United States from the late 1870s, which marked the beginning of modern District Heating. Steam distribution was the only recognized technology for more than a century. As the District Heating demand increased, the energy engineers began to see an alternative in using water for heat distribution.

According to some research, District Heating with combined heat sources has one of the highest efficiencies of all heat generation technologies. For example, nowadays the combination of DH Systems with Thermal Storage is widely recognized as a technology that can help to manage intermittent renewable energies in the electrical grid. Also, it was demonstrated that District Heating plants can provide higher efficiencies and better pollution control than localized boilers.

The evolution of DH systems along history is often classified by researchers into “generations”. We are currently in the Fourth generation of District Heating systems (2010-2050), where the production comes from primary resources with renewable energies, the combination of thermal energy storage and the recycling of heat resources such as waste heat or industrial heat dissipation by means of a heat pump system.

According to several authors, some of the District Heating Systems that are currently developed belong already to the 5th Generation.

The Fifth Generation of District Heating and Cooling systems will be decentralized, bi-directional, with temperatures close to the ground temperature and they will use a direct exchange of warm and cold return flows. The large scale of 5th District Heating allows the utmost engineering designs, developing technical solutions like heat pumps and thermal storage tanks. In order to move to a sustainable heating and cooling sector, it is essential to invest in energy efficiency to lower overall demand and to replace fossil fuels with more sustainable energy sources.

The production plant provides hot water, which can be generated specifically for the District Heating system using heat pump technology. This technology utilizes renewable energy sources such as solar thermal, geothermal, biomass, waste incineration combined heat and power (CHP), or biogas boilers.

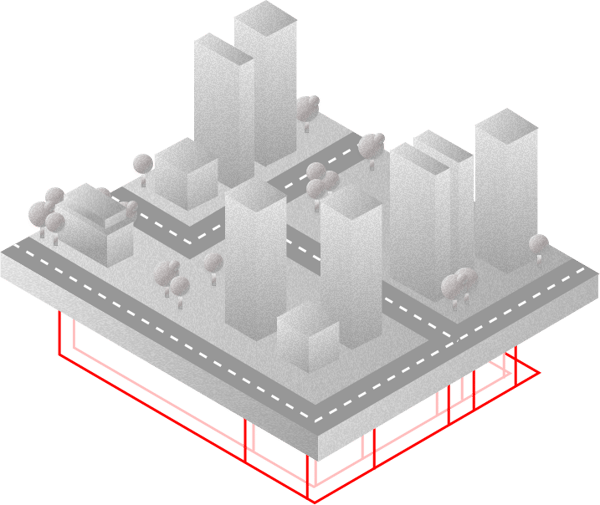

The Distribution Piping Network (DPN) conveys energy in the form of hot water through pipes from the thermal production plants to the consumers. It is a closed piping loop that also drives the low-energy water back to the production plant, once the consumers have received the heating energy.

Energy Transfer Stations (ETS) are in-building equipment where the energy is delivered to the final users.

Customers are connected to a District Heating (DH) network via substations. Each substation consists of two heat exchangers, one for space heating and the other for domestic water heating, where the DH heats the water of the building’s central hydraulic system. This hydraulic system, present in each building, will drive the heat to the fan coils, the radiators, or the underfloor heating in order to heat spaces.

Different components of the District Heating System need to operate and perform all together as a single and fully integrated system. The best practice is to integrate everything into one single Control System, containing all the information regarding the main equipment (boilers, heat pumps, cleaning devices) and the Energy Transfer Stations (ETSs).

Since the arrival of the first District Heating systems over a century ago, the efficiency has increased sharply. Heat sources and heat generation technologies are more diverses and the potential for grid connection is higher. At ARANER, we focus on improving the efficiency and we innovate to promote lower flow temperature to the networks, waste heat recovery usage, operation during low-cost electricity time periods and combination with thermal energy storage.

Heat pumps use electricity to extract heat from free, renewable low-temperature sources with high-efficiency rates. Heat pump usage is best suited for low-temperature demands and can provide renewable and efficient heat at low operational costs. Additionally, the use of heat pumps promotes synergies with the electricity grid.

ARANER takes its role in reducing overreliance on fossil fuels seriously. Our high-quality heat pump technology is effective in District Heating systems, as it captures heat from unlikely sources such as industrial wastewater, groundwater, air, and seawater. Recycling heat is particularly impressive because it minimizes carbon dioxide emissions and reduces energy costs. For optimal District Heating application, a large-scale heat pump system is often necessary depending on the available heat source: Air Source Heat Pumps, Ground Source (Geothermal) Heat Pumps or Water Source Heat Pumps.

SEE HEAT PUMPSThermal Energy Storage (TES) plays an important role combined with the District Heating Systems, as they balance the thermal demand with the different energy production sources. Heat District Energy Systems with TES accrue three main benefits:

• Accumulates thermal energy during off-peak periods for application during periods of high demand

• Helps utilizing renewable heat sources such as solar energy more effectively

• Stores surplus thermal energy to prevent wastage and allows for supply during periods of higher demand

ARANER can assess the project and retrofit a DH system already in operation as per ASHRAE recommendations. This presents a big benefit in terms of enhanced peak heating capacity. For the TES design, it is recommended to develop a load profile study and a heat generation economic overview, in order to obtain the optimal balance between demand and production. Technologies employed:

• Sensible or latent heat

• Daily or seasonal accumulation

• Centralized or distributed location from the network

Green and circular economies develop a new player: The Prosumer

Reduced CO2 emissions and significant contributions to decarbonize large EU cities

Reduced cost of operation

Reduced consumption and installed power per building

More predictable and reliable energy sources due to the dependency’s reduction of fossil fuels

More spacious and cleaner buildings with LOWER POLLUTION

Synergies with renewable energies and use of waste heat source

The highest efficiency for your project energy demand. Heat energy is provided from a central heating plant, thus eliminating the need for separate systems in individual buildings.

Find the know-how and all you need about District Heating projects and much more.

Solve any doubts through our frequently asked questions or ask for advice

FAQ's about DHWe create solutions and guarantee success by taking full responsibility of the overall project.