DISTRICT COOLING

An environmental solution for the present and our future

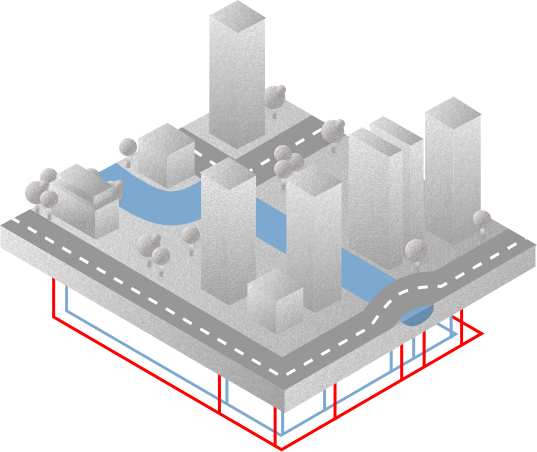

Within the District Energy Technologies, a District Cooling Plant distributes thermal energy in the form of chilled water from a central source to multiple buildings or consumers through a network of pipes. The cooling energy is provided from a central cooling plant, this eliminating the need for separate systems in individual buildings. This solution is interesting when there is an appreciable concentration of cooling loads, such as densely populated urban areas and high-density building clusters, and can offer economic and environmental benefits.

In general, District Cooling offers several advantages when compared with traditional cooling solutions.

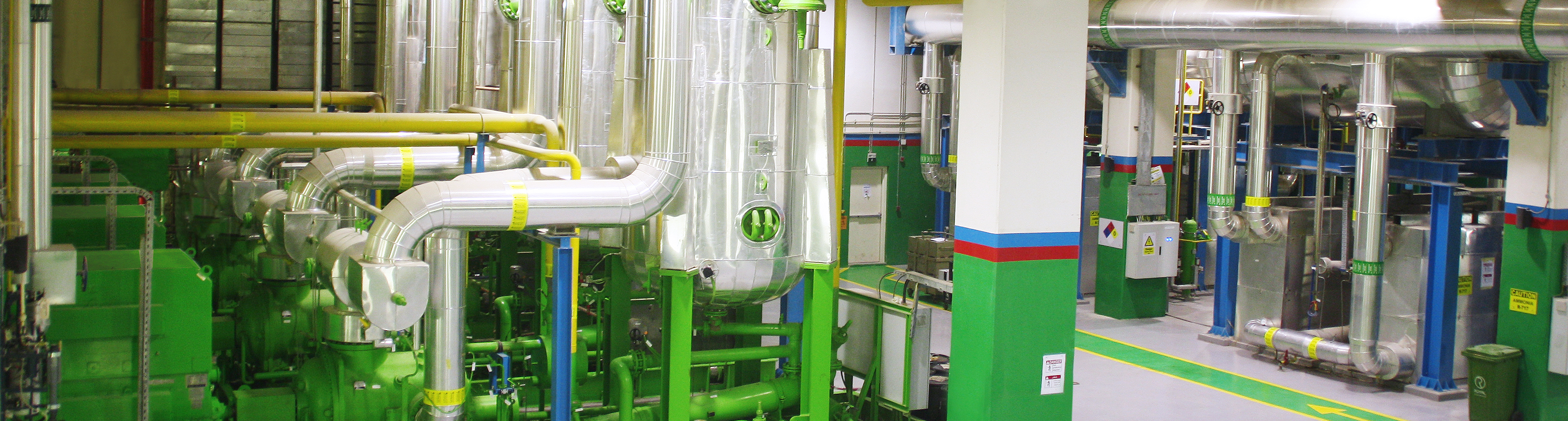

DC is a safe business with quite stable demand and relatively low payback periods. As production takes place in an industrial environment, it is always subjected to optimization and to the improvement of efficiencies and installed cooling capacity.

The capital cost and operation cost are reduced. In addition, the cooling equipment, which can be noisy, is usually placed outside the building (sometimes remotely) and the maintenance operations are often outsourced.

The implantation of a DC System makes cities more sustainable since it is a more efficient solution than the installation of stand-alone chillers. This means a reduction of the energy consumption and of the CO2 footprint. Also the city skyline benefits by eliminating the installation of individual cooling equipment systems.

When a DC is designed for several buildings with diverse usage, the demand can greatly differ among the different cooling consumers. Building energy efficiency legislation has traditionally focused on space cooling energy consumption. However, more renewables energies will be used in the future, both from the grid and self-produced. Then, the origin of the energy production and the CO2 emissions will gain relevance.

If the network is well balanced, the production plant size can be optimized by adding some thermal storage technology.

ARANER has a very substancial experience as EPC contractor for the construction of traditional plants, but we always put our best efforts to add value to end-users.

One of the huge innovations in Araner’s DC Plants is to provide a reliable solution for locations where water conservation is critical, like the Middle East Areas. With this technology, heat is rejected to the ambient air. Air fans are installed to circulate the proper airflow through a fin and tube heat exchanger.

These high capacities and high-efficiency air-cooled chillers are the best solutions to the water-to-energy nexus and the best solution for areas with water scarcity. A lot of problems are solved thanks to this system, not only related to the water supply but also to the blowdown discharge, legionella, etc.

The District Cooling plant may reject the heat derived from the cooling process with a cooling tower. Cooling towers are available in different types and sizes depending on the load configuration. In cooling towers, water is sprayed and evaporated over air streamflow. The coolant fluid is the water that will evaporate at an ambient wet-bulb temperature which usually is lower than ambient temperature, reducing the condensing pressure.

This is the most traditional solution for District Cooling plants. However, the water consumption of this technology is high and the chemical treatment and other operation costs shall be added to this technology.

ARANER’s sea water-cooled plants are the optimal solution when the District Cooling System is constructed near the seashore. The solution provides a low condensing temperature with ZERO freshwater consumption. Seawater is supplied through the titanium condenser and then is returned to the sea. All the typical environmental restrictions (like the maximum seawater return temperature) can be solved with ARANER plants.

The DC Control System is the key component for a successful operation of the cooling plant, because different components of the District Cooling System need to operate and perform all together as a single and fully integrated system.

ARANER Control System for District Cooling Plants provides a new concept in DC plant management. Not only a completely automatic and well-performance plant is required by most demanding clients, but also an in depth data treatment analysis is valued as advantage in modern District Cooling Plants.

With a very user friendly SCADA and Human Machine Interface (HMI), full control and plant integration is achieved. Our control systems are based on the latest PAC (Programmable Automation Controller) technology for the highest performance and durability. Systems also are equipped with a suite of tools that allow the creation of fully customizable features.

ARANER Billing System provides the owner the capability to extend weekly or monthly invoices to each client with a fix cooling water price or variable one, depending on the electricity cost or the time scheduled consumption.

ARANER Reporting Services allows the maintenance team to receive a daily report of the maintenance activities to be done as well as it advises if any equipment is having an unusual performance. Furthermore, the reporting services provides monthly and weekly a report to the management team showing the KPIs (Key Performance Indicators) compared with previous periods.

ARANER Performance Optimization System checks several parameters such as the weather forecast, the weekday, the electricity price, etc. and selects how many chillers and when have to be running, in order to reduce energy costs.

Thermal energy storage is adding many benefits to District Cooling plants: peak load saving, efficiency increase, plant reliability, and availability improvement.

Implementing a Thermal Energy Storage is the best way to boost the efficiency. With TES Tanks, part of the cooling energy production is transferred from daytime, when temperature is high and chiller efficiency is low, to night time, when efficiency is higher. The overall efficiency all around the year is significantly increased.

However, some older DC plants do not have a TES tank yet, but it is never too late. This solution can be added to retrofit DC plants in operation. In fact, in plants which are already in operation, adding a TES system will add another benefit: peak cooling capacity increase.

From a technical point of view, the critical issue is to study the hydraulics of the system. An extra pumping group might be required depending on the case. It is also important to modify the control system, so that the TES is integrated.

Recognized GREEN TECHNOLOGY with carbon credit

ARANER approached this project having to deal with a key underlining problem: the scarce availability of water.

A guide about the benefits, main design parameters and the DC up-to-date technologies

Solve any doubts through our frequently asked questions or ask for advice

FAQ's about DCWe create solutions and guarantee success by taking full responsibility of the overall project.