HEAT PUMPS

The Heart of the District Heating Plant

Heat Pumps are considered the most efficient and cost-effective heating technology in the marketplace. They are remarkably environmentally friendly and can drastically reduce your carbon footprint and energy bills. They offer an ideal way to heat your property and produce hot water whilst saving money and the earth’s precious resources.

All major associations that promote decarbonization suggest that heat pump technology is the most suitable solution combined with renewable energies to play an accelerator role in their purpose.

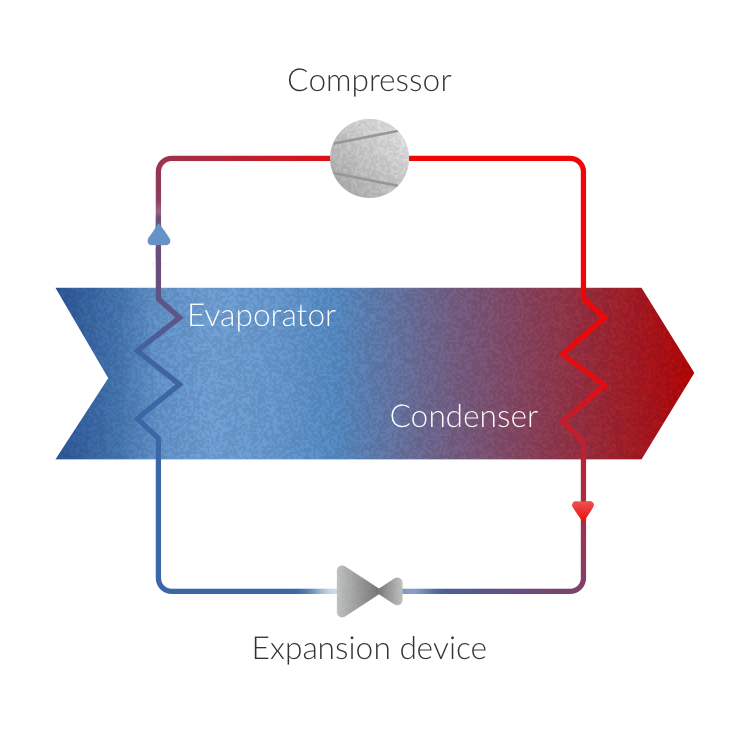

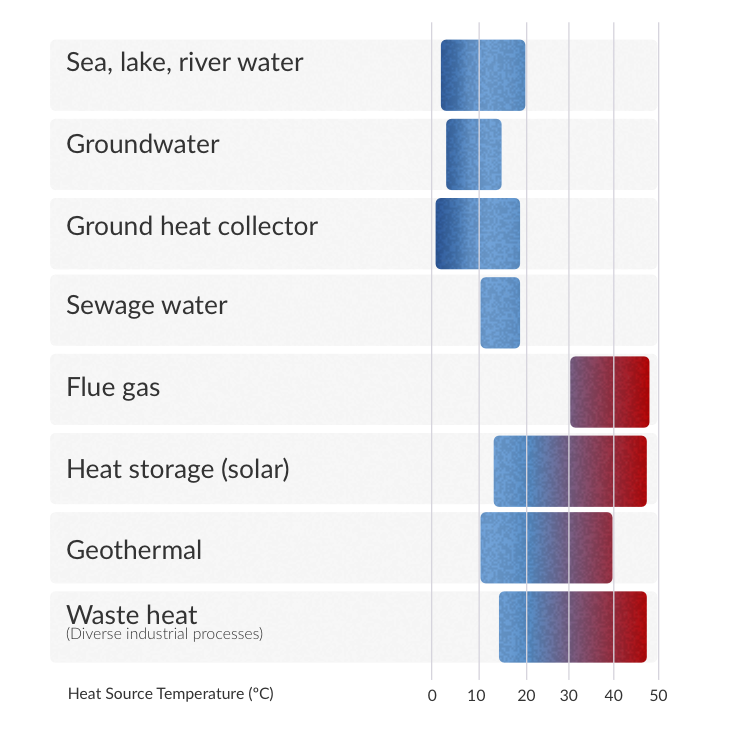

Heat pumps transfer heat from a lower temperature system to a higher temperature one, thanks to the refrigeration cycle that they perform in between. Heat is taken from a heat source, where normally the temperature is not controlled. The heat is transferred to the consumer, which will depend on the application. The heat pump can be used in a wide range of fields, from commercial to industrial size.

They are suitable for air conditioning, District Heating, industrial process (drying, washing, pasteurization, etc.) or to increase power generation. Heat pumps are used as an alternative to traditional boilers and electric heaters to produce heat energy, as the efficiencies that they can achieve are higher when there is a suitable heat source available.

ARANER offers three types of heat pumps depending on applications and design key factors to obtain the most suitable solution. Our heat pump will cover a full range of processes and hot water temperatures using different technologies and applied systems. Heat pumps can be useful for heating residential or commercial spaces in a district heating but at the same time a cost effective solution in a drying industrial process, where they also minimize energy usage.

Medium size heat pumps have been used for a long time in several applications in food and beverage industries employing ammonia as refrigerant (R717).

R717 is a natural refrigerant and has been adopted as a definitive solution in many countries. This refrigerant is employed depending on the demand of the heating processes. High-pressure reciprocating compressors and screw compressors have been used to obtain higher efficiencies than other heating systems (such as boilers) reducing CO2 footprint.

During the last decade, Very High-Temperature Heat Pumps (VHTHP) have been developed to substitute other fuel energies employed for drying processes. For these cases, HFC and in the last years HFO are used to obtain hot water temperature over 90ºC, as a single refrigerant or in cascade systems. For some countries, ammonia heat pumps are the unique friendly solution due to environmental regulations and large screw systems will be implemented in the following years.

Screw compressors are positive displacement compressors encasing a mass of refrigerant in a decreasing volume during the compression process. They provide excellent lift characteristics:

Large centrifugal R22 systems have been commonly employed in the 80´s during District Heating development in the Scandinavian countries after the fuel crisis. They have developed policies and directives for creating large heating systems based on biomass, waste or electricity.

These systems are now being renewed using HFC and they are connected to a diversified District Heating with a large network.

The next large District Heating projects will employ these large centrifugal heat pumps with a new generation of refrigerants with low GWP and some cases with natural refrigerants.

Centrifugal compressors are a non-positive displacement compressor type and therefore they are more sensible to a pressure differential lift between evaporation pressure and condensing pressure:

Absorption systems, instead of using electricity, use ‘heat’ as the energy source, a low- grade energy.

The energy source may be steam, hot water or even waste heat, like in exhaust gases from an engine (gas or oil based). ARANER offers a wide range of solutions for each of these energy sources, representing a major progress in the absorption refrigeration technology for heating purposes.

Our absorption heat pumps can be installed in a cogeneration plant as a heat recovery system, in order to reduce steam consumption. It can be also used on the flue gas condensation for improving the system efficiency.

ARANER absorption heat pumps uses tested components and procedures for industrial refrigeration applications. Their main characteristics are:

COMPACT SIZE compared to other HP solutions

INTEGRATION FLEXIBILITY with renewable energies

Short downtimes and RELIABLE PERFORMANCE

SUSTAINABLE solution for the environment

We create solutions and guarantee success by taking full responsibility of the overall project.