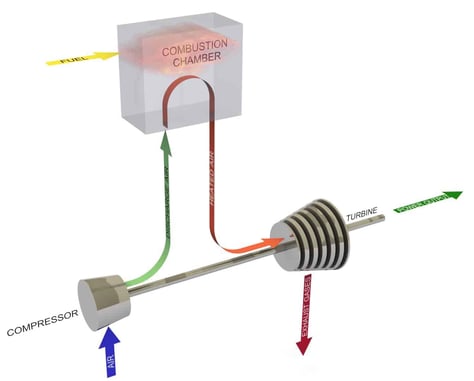

People keep inquiring about CCGT (Combined Cycle Gas Turbine) and OCGT (Open Cycle Gas Turbine) systems, cause of the popularity of natural gas for power generation. But as with all products, each of these systems has its pros and cons. The OCGT has a rather straightforward operation that starts with fresh ambient air entering the compressor and ends with power generation as shown in Figure 1 below. This simplicity gives to OCGT several advantages over CCGT. However, do not get it all wrong; this cycle has also some drawbacks that may hinder its application in certain circumstances. Considering all these facts, when are open cycle gas turbines the right option?

How Open Cycle and Combined Cycle Gas Turbines Compare

To help in choosing between open cycle gas turbine (OCGT) and combined cycle gas turbine (CCGT), it would be worthwhile to compare the two based on efficiency, economics and environmental effect.

1. Efficiency

There is no denying it; CCGT technology remains the choice for many power plants that rely on natural gas. Efficiency of this device is the driving force, and it seems to be getting even better. Recent developments have allowed for higher efficiency (to the tune of over 60%). Analysts in the sector are already forecasting that efficiency will have hit the 64% mark by 2020. The recent development in the power augmentation platform must be exciting power plant owners, especially those that manage combined cycle power plants. ARANER deals in Turbine Inlet Air Cooling (TIAC), one of the most reliable power augmentation technologies for the gas turbine. Leading open cycle turbine manufacturers are trying hard to enhance the efficiency of these products, but the figures attained so far are much lower than the 60%-plus of CCGT.

2. Economics

When choosing the CCGT, you must look at the fiscal factors keenly. The technologies for setting up a combined cycle power plant are complex and high as compared to the OCGT. Sometimes, the O&M and initial capital costs can exceed the savings realized from higher efficiency. However, this technology is still viable for a new facility, looking at current prices for equipment and fuel. The flexibility of CCGT is very impressive in both economic and technical aspects. Historically, these plants do not run continuously, but rather only switch on during peak load periods. Because of this, this technology has been widely embraced in wind power and other renewable options. (Various troughs and peaks usually characterize renewable energy production). Note also that the setup can run on virtually any type of fuel including methane gas, biogas and oil.

3. Environmental Effect

Power plants may affect the environment during both construction and operation. Effects include taking up space, pollutant emission and use of water resources. Furthermore, the height of the facility can be a hindrance to aviation activities. While any power plant can have effects on the environment, most people prefer the combined cycle power plant to the open cycle gas turbines. US power plants that have gone this route are reporting fewer emissions. The significant reduction is reported for pollutants such as sulfur dioxides (SO2), carbon dioxide (CO2) and nitrogen oxides (Nox). The open cycle gas turbine discards waste heat into the atmosphere, something that can have adverse effects on the environment. The CCPP does not feature such a concern because it reuses waste heat to generate more power. At the end, the choice is yours but independently of your choice, ARANER products can help your OCGT or CCGT to work in a more efficient way.

OCGT: how to make the decision

Before you choose between these two power generation systems, you should ask yourself some questions.

How important is efficiency for your plant?

When it comes to efficiency, OCGT systems have lower efficiency (around 40%) than CCGT, which can reach efficiencies of up to 56 – 60%. In this way, CCGT may be the best option in power plants where efficiency is a key point.

What type of power are you looking to generate?

If you are using the turbine for peaking power, you had better use OCGT since the start-up time is shorter than for CCGT. But these are not the only factors to take into consideration. Below you will find three scenarios for which OCGT overcome CCGT for power generation.

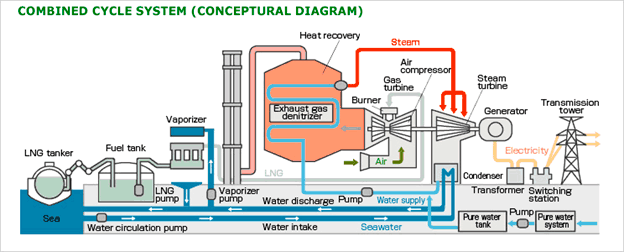

First scenario: when you don’t mind about waste heat

A CCGT comes with a heat recovery system that captures waste heat from the exhaust gas of the gas turbine. Using this waste heat, the Heat Recovery Steam Generator (HRSG) generates steam that goes to the steam turbine. From the steam turbine, the power plant is able to generate more electricity. In other words, the combined cycle gas turbine maximizes efficiency. Contrary to the above system, an OCGT does not capture waste heat. Instead, this system must reject the waste heat to the environment. Thereby, if your power plant does not need to recover the waste heat to increase the power output, OCGT may be the best option.

Second scenario: to solve the peak power demand problem

No doubt, CCGTs are more dominant than OCGTs for the generation of base-load and intermediate-load power. However, OCGT are more dominant for peak-load power demand. A perfect example is in the UK, where the Secretary of State (SoS) for the Department of Energy and Climate Change (DECC) recently gave consent for the construction of an OCGT for the Abernedd Power Station for back up electricity, where a fast response is needed. One problem with peak power is its unpredictable nature. If temperatures go higher, the peak electricity demand can exceed expectations. Only a power plant that can ramp power quickly will be able to compensate for this demand. What better to do this than to use an OCGT? OCGT power plants are used to serve as security for electricity grids that have integrity issues. This includes failures in transmission and generation systems.

Third scenario: when space is limited

Choosing a site for a gas-fired power plant is not a simple matter. Availability of space is one of the most important project parameters to keep in mind. In CCGT systems, steam turbines and waste heat recovery units take a lot of space and are quite heavy. Using an OCGT is a way of using the least weight and space possible. For a small space, you will have a hard time figuring out where to place the additional equipment that come with a CCGT.

ARANER: efficiency in combined cycle plants

Selecting an open cycle gas turbine technology is normally a compromise between fixed cost and marginal cost. This compromise is based on plant utilization. If a facility is to be used regularly, then efficiency is expected to be high. Consequently, the owner must be prepared to pay a higher fixed cost (investment). This means that a CCGT would be the most suitable solution. If the plant operates only for short periods of time, it might be more economically feasible to avoid high fixed cost even if the efficiency is low. That way, recovery of investment over the turbine’s lifetime is almost a guarantee.

Obviously, it is not easy to decide for either OCGT or CCGT considering that you also have to consider fuel availability, demand profile, logistics and so on. To sum up, it is worth stating that with the increasing energy demand, power producers must make technological choices with more keenness. ARANER performs thorough engineering studies to factor in all the constraints of a project. This includes considering TESTIAC technologies for efficiency improvement, which is the trend nowadays. If you like this article, then you must read this about the efficiency of combined cycle power plants