Optimizing the way energy is used in a data center goes far beyond improving the efficiency of backup generators. Generators fulfill a single mission-critical purpose: providing power during an outage. Their role is not continuous operation, and therefore their efficiency has a limited impact on the overall energy balance.

By contrast, Cogeneration (CHP) and Trigeneration (CCHP) can reshape the normal energy supply model when conditions allow, enabling on-site power generation and thermal energy recovery that can significantly improve the overall efficiency of the facility—not the efficiency of the generators themselves.

Although CHP and CCHP do not replace UPS or emergency generators, they can reduce dependence on the grid, lower operational costs, and enable circular energy strategies when a real, continuous thermal use is available.

This article examines how these models work, when they make sense, and what realistic benefits they can bring to data center operations.

From Energy Consumption to Energy Optimization

As data center electricity demand grows—driven by AI, cloud, and high-density computing—the focus has shifted from merely reducing consumption to making better use of every unit of energy consumed. The key opportunity lies in recovering energy that would otherwise be wasted.It is essential to clarify the distinct sources of heat:

- Heat from IT Equipment (Exhaust Air): This is low-grade heat and is only suitable for recovery when paired with heat pumps to raise the temperature to usable levels. Its recovery is generally a separate process from CHP/CCHP.

- Heat from the Primary Generation Plant: In CHP/CCHP systems, the recovered heat comes exclusively from the engine or turbine driving the generator in the plant (e.g., a gas turbine, or a central power source like nuclear or biomass).

When a continuous generation source, such as a nearby power plant, is the starting point, its waste heat can be leveraged for efficiency gains for the fuel used that cannot be achieved through electric-only generation. Furthermore, grid constraints are compelling operators to evaluate on-site energy production as a strategic complement to traditional electrical supply.

- Cogeneration (CHP): On-Site Electricity + Useful Heat

- Cogeneration (CHP), or Combined Heat and Power, is the process of capturing the waste heat produced during electricity generation and using it for heating or industrial processes.

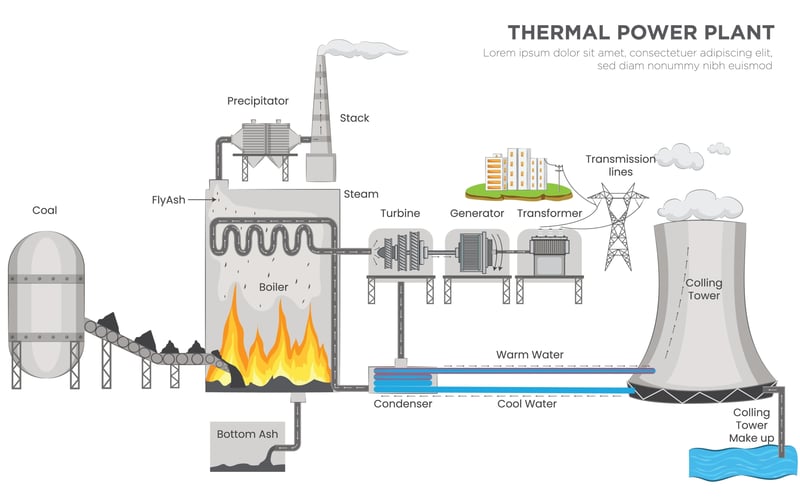

Source: Shutterstock Explore

The Principle of CHP Operation in Data Center Integration

The CHP system uses the fuel source (commonly natural gas, biogas, or synthetic fuels) of a power plant to drive an engine or turbine that produces electricity. The waste heat from the engine block and exhaust gases is captured via heat exchangers.

In this integration model, the recovered heat can then be piped to the data center or a nearby district heating network for continuous use.

Benefits in the Data Center Context

A generation plant might operate with electrical efficiencies around 38 - 45%. However, by implementing CHP, the overall fuel-to-energy efficiency can reach 80 - 90% when there is a continuous, real use for the recovered heat.

For data centers, integrating with a continuous CHP source can offer:

- On-site power generation, reducing dependence on the electrical grid.

- Increased fuel-to-energy efficiency via heat recovery.

- Lower operating costs when fuel prices and electricity market conditions are favorable.

- Lower emissions compared to separate electricity and heating production.

- Opportunities for integration with district heating networks, creating a circular energy model.

The feasibility of CHP depends entirely on the external thermal demand profile. Without a continuous and economically viable use for the heat, the system loses much of its value.

- Trigeneration (CCHP): Adding Absorption-Based Cooling

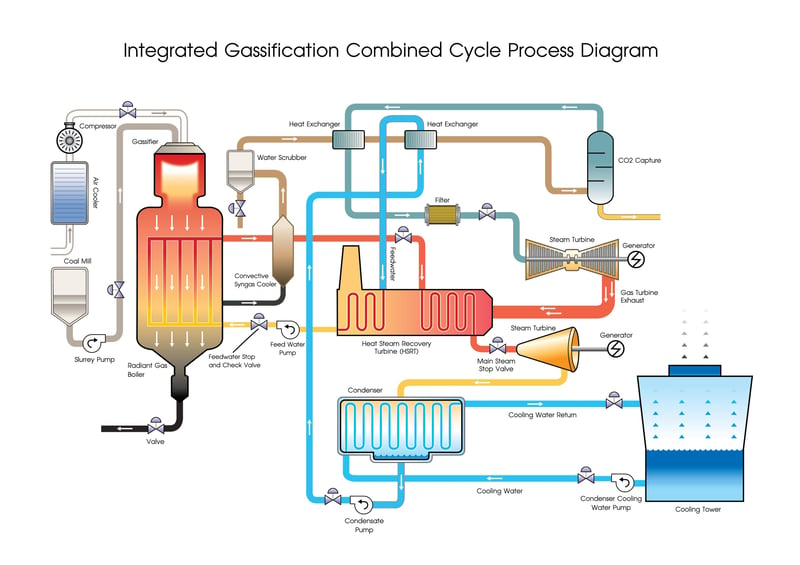

- Trigeneration (CCHP), or Combined Cooling, Heat, and Power, is an extension of CHP that adds the capability to produce cooling from the recovered waste heat.

Source: Shutterstock Explore

How CCHP Works

The waste heat recovered from the CHP system is used to drive an absorption chiller, which produces chilled water. This cooling can then supplement the data center’s primary mechanical cooling systems.

Constraints and Realistic Applications

Using absorption cooling can reduce electrical consumption for cooling, which is particularly valuable in markets where electricity prices are high. It can also be beneficial in hybrid district heating/cooling schemes.

However, several critical constraints apply from an infrastructure engineer's perspective:

- Thermal Dependence: Their operation is entirely dependent on the continuous availability of thermal energy from the CHP system.

- Efficiency (COP): Their efficiency (Coefficient of Performance, e.g., 0.7 for single-effect) means they are best used where thermal energy is abundant and inexpensive.

When these conditions align, CCHP can reduce total energy costs and improve the overall fuel-to-energy efficiency.

When Do CHP and CCHP Make Sense for Data Centers?

CHP and CCHP are not universal solutions. They are most suited for data centers operating under specific technical and economic conditions:

- Sites with Grid Limitations: Locations with limited grid capacity or long grid connection timelines.

- Fuel Availability and Cost: Locations with competitive gas prices or reliable access to alternative fuels like biogas or synthetic fuels.

- Thermal Offtake Capability: Data centers that can export heat or integrate into district heating networks.

- Load Profile: High-load facilities with predictable 24/7 energy demand.

- Sustainability Goals: Operators seeking improved sustainability through combined heat and power cycles.

Conversely, they are generally not suitable when:

- No Viable Thermal Use: There is no viable thermal use for the recovered heat, either on-site or off-site.

- Fuel Volatility: Gas availability is constrained or subject to significant price volatility.

Conclusion: Synergy as an Efficiency Strategy

The integration of CHP and CCHP systems, when leveraging the waste heat from a continuous generation plant (not emergency backup), represents a high-value energy optimization strategy. They do not replace UPS, backup generators, or critical cooling systems, but they complement the traditional data center architecture by:

- Reducing grid dependence through on-site generation.

- Significantly increasing fuel-to-energy efficiency via heat recovery.

- Lowering operational costs under the right market conditions.

- Enabling circular models with district heating or supplemental cooling.

These technologies offer a viable pathway to achieve maximum sustainability and operational resilience in contexts of grid constraints, rising energy costs, and strong sustainability goals, provided they are implemented where they are technically and economically justified.

Want to learn more about how to optimize data center power generation through advanced thermal engineering strategies such as cogeneration and trigeneration? Discover our data center reference ebook and data center cooling solutions, and get in touch with us to speak to our team about how we can help you.