The world wastes a lot of heat every day. Take for instance the amount lost in traffic. As you press the gas pedal of your car, the tailpipe emits waste gases at a temperature of between 300 and 500̊C. Scenarios like this one make experts think about heat generation from waste heat. Globally, the heat waste potential is astounding. Experts have identified waste heat as a significant contributor to global warming. This is based on the law of conservation of energy, which states that energy can only be converted from one form to another - it can never be destroyed. So, how good would it be for an industry to have the capability to transform its waste heat into power? The industry can generate power and sell waste heat for more profit. With the recent growing interest in clean and high-efficient energy, waste heat can do more than just supporting District Heating and Cooling systems. It can actually produce substantial power.

Different Options for Waste Heat Recovery

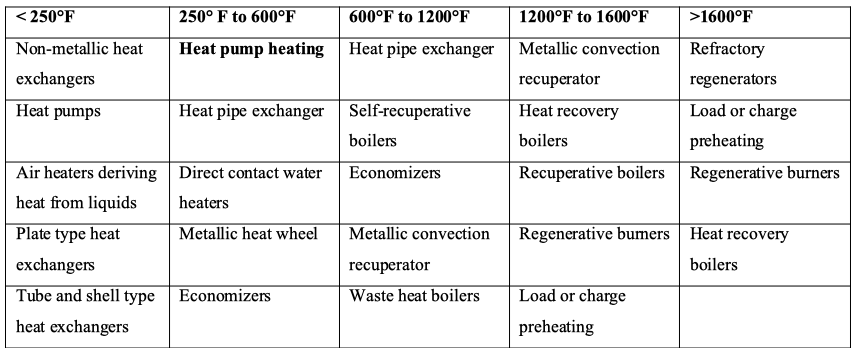

There are different technologies for capturing heat waste in applications across the world. Most of these solutions are industry-specific. Due to the wide range of customizations available, it is not always easy to classify the solutions in a standard manner. Perhaps, the best categorization criterion is temperature range. Based on temperature range, some heat waste recovery methods include the following:

Fig 1: Waste Heat Recovery Technologies (source: Bian, 2020) Furthermore, most of the technologies in the market are under continuous improvement to achieve things like:

- Footprint

- Thermal efficiency

- Manufacturing and operation cost

- Maintenance costs

- Evolving customer demands

Heat Waste for Power Generation: Some Popular Technologies

Clean energy generation has mostly focused on wind and solar technologies, solutions that have proven to be sometimes unmanageable based on dollar-per-watt. Heat waste for power generation is not only more affordable on this basis, but also more suitable for baseload power. The waste heat area offers enormous heat power, for instance, the one that emanates from an oil refinery, chemical plant operations, industrial operations, mining and even power generation. For waste heat to generate power, several technologies come into play. These processes may have an intermediate mechanical section, but the result is still power.

Organic Rankine Cycle

Processes under this category use liquids with lower boiling pressures and temperatures as compared to water. Because of this, ORC processes tend to offer low efficiencies. The efficiency range is usually between 10 and 20% for temperature levels up to 350 degrees centigrade.

Steam Process

Water vapor powers a steam turbine connected to an electric generator. Capable of reaching 540°C temperature level, steam processes have a higher efficiency of as much as 42%.

Kalina Process

These complex processes rely on ammonia solution. They are renowned for superior adaptation and sizeable heat exchangers.

Stirling Process

The most important components of this process type are the working gas and the mechanical shaft. Application or removal of heat depends on the expansion or contraction of the gas, leading to shaft rotation.

Choosing Best Technology

Using any of the above options to generate clean and high efficiency energy is a lengthy process that starts with a feasibility study. A feasibility study helps answering many questions including the type of fuel, the gas characteristics and the availability of cooling water. The contractor should then proceed to help the client to calculate various aspects of the power generation, select the manufacturer and determine how the system will operate. Construction planning, installation and tests follow these steps. It is important to offer installation support to ensure smooth running of the power generation facility.

Conclusion

Are you in steel milling, cement manufacturing, petroleum refining, natural gas compression or related businesses? What are you doing with all the waste heat from your operations? It is possible to reduce power consumption, protect the environment, promote sustainable development goals (SDGs), and fulfill your corporate social responsibility. All this can happen if you can transform your heat waste into power.