Did you know District Energy Systems are essential for our cities in order to fight climate change, while remaining cost-effective and energy-efficient? The role of industrial heat pumps is key.

Focusing on Europe, one of the main pollutants when it comes to CO2 emissions is ‘the heating of buildings’. An outstanding solution for this issue are industrial heat pumps: a clean, affordable and efficient way of heating.

Even though we can find multiple methods to generate the heat needed in a District Cooling & District Heating Network (geothermal, thermal solar, heat storage, etc.), heat pumps are a clear solution which have been growing more popular lately.

Nowadays, they are being widely implemented in Northern Europe and North America and have become a key part in the industrial, commercial and residential sectors. In Scandinavian cities, almost all heating services are being delivered through low-carbon, centralized district energy plants. According to the UNEP - The Environment Program from The United Nations - a modern DCH System should have innovative technologies such as the one provided by industrial heat pumps.

But, what exactly is a heat pump?

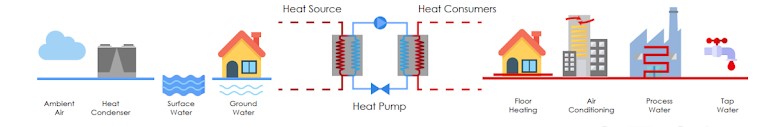

Industrial heat pumps transfer heat from a lower temperature system to a higher temperature one, thanks to a refrigeration cycle that takes place between each of these steps. First, the energy is extracted from a heat source and then this heat is transferred at the right temperature, through the pump, to its final consumers or users.

Heat pumps can be used in a wide range of fields, from residential to commercial or industrial size. They are an alternative to traditional boilers or electric heaters which produce heat energy, as well as the efficiencies they can achieve are higher when there is a suitable heat source available.

What's the role of heat pumps in district energy?

As we say in Araner, heat pumps are the heart of the heating plant. They have multiple applications and especially, their role within District Cooling & Heating Networks will be increasingly important for future renewable energy systems.

What are the benefits of a heat pump and why is the right choice for my organization?

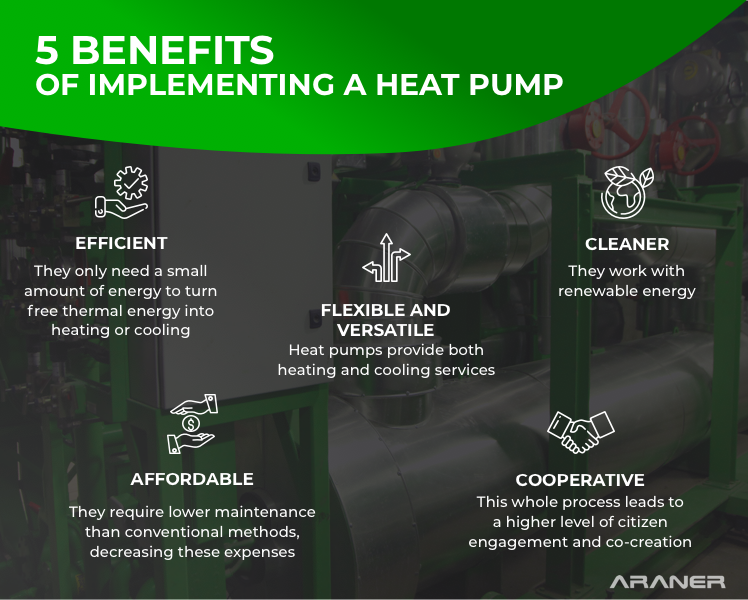

1. Efficient.

They only need a small amount of energy to turn free thermal energy into heating or cooling.

They keep energy consumption as low as possible, which is strongly seeked for given the rising energy costs.

2. Flexible and Versatile.

Unlike other heating options, industrial heat pumps provide both heating and cooling services.

3. Cleaner.

Heat pumps can use “free” renewable energy by extracting thermal energy from already existing sources, such as outside air, soil, seawater, etc.

They provide one of the best solutions for decarbonization. They reduce fuel dependency, decrease carbon emissions drastically and improve air quality; which is not only the best for the Earth, but our health too (short and long-term wise).

Another highlight is the utilization of natural refrigeration. Instead of phased-out options which are no longer valid and can be detrimental to our planet, natural refrigerators such as ammonia and propane can be implemented for heat pumps, protecting our ozone layer.

4. Affordable.

Costs are divided among multiple users and stakeholders. We should consider end-consumers, government bodies, engineering companies and environmental agencies among others.

Both the public and private sectors tend to collaborate into finding the most appropriate business-finance model to achieve a higher ROI.

Additionally, industrial heat pumps require lower maintenance than conventional methods, decreasing these expenses.

5. Cooperative.

This whole process leads to a higher level of citizen engagement and co-creation. Also, if there are more benefits within the local economy, more local jobs can be created.

Why are heat pumps the future in energy integration?

Simple. Because they keep up with the market trends that allow for cost-saving and energy-efficient solutions, while also setting the path for a sustainable, low-carbon transition. Here are three reasons why:

1. Circular Economy

Circular Economy aims to reach a transition towards renewable energy sources by redefining our current system in order to reduce consumption and, as a consequence, reduce the amount of waste we produce and make efficient use of it.

Thanks to heat pumps we can achieve sustainable DCH’s: Industrial heat pumps minimize negative impacts by making the most of available local energy sources and recovering (waste) energy. Moreover, they can be fully integrated with other renewable energies.

2. Carbon Neutral Compliance

Businesses should reach a net-zero carbon footprint by 2050. Many regions are already presenting new policies to guarantee this: bans, tax reforms, fossil fuel subsidy reforms, etc.

Therefore it is key to take some steps ahead and be prepared. District Cooling and District Heating Networks can promote this decarbonization, ensuring efficiency improvements and an ecological transition.

3. 4th Generation and 5th Generation District Heating

4GDH and 5GDH lead the evolution to smart cities. Future District Heating Networks will be designed following a low-temperature flow, minimising heat loss and greenhouse gas emissions.

Actually, moving towards the 5th (and even the 6th) Generation, there will be a much stronger focus on combining heating and cooling. We will start talking of District Energy Systems, rather than cooling and heating separately. This will be facilitated by seasonal storage as well.

In this case, heat pumps are one of the best alternatives. On the one hand, thanks to their low energy demand and integration of renewable energy sources. On the other hand, because they already provide cooling and heating.

Therefore, heat pumps are not lonely workers in your District Energy Network, there are other technologies that improve the process as a whole, such as Thermal Energy Storage tanks (TES). If you want to know more about how they balance energy demand during high-cost peak times, just read our following article on TES.