What is power quality? Power quality is not an easy term to define, as there are many factors that could be involved in the definition, but in broad terms power quality is usually related to following concepts:

- The deviation of voltage and currents from the ideal sinusoidal waveforms

- The electrical efficiency of the plant

- Reliability

But, what impact do power quality problems have on a Cooling Plant? Why is power quality analysis so important?

Efficiency: Power Factor

Most loads in a Cooling Plant are inductive, which includes motors and transformers as main loads. These need a magnetic field to operate. Inductive loads require two kinds of power: Active power (P [Watts]) to perform the useful work, and Reactive power (Q [VAr]) to sustain the magnetic field. Active power and reactive power together make up Apparent power (S [VA]). Power factor is the ratio of Active power to Apparent power, as per below formula:

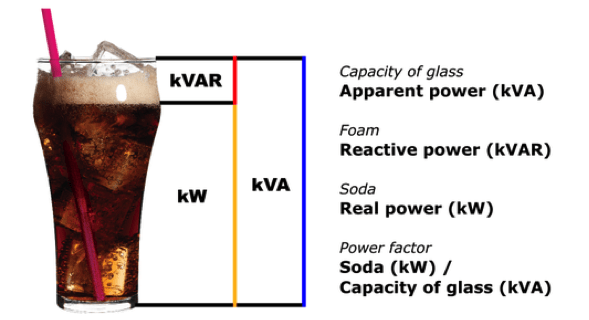

Power Factor is an indicative of the plant efficiency, as it is the ratio between the total power consumption and the useful power consumption. A low power factor implies that the customer is not using all the electrical power that is paying for. For example, take a glass of soda. The capacity of the glass represents apparent power (kVA), the summation of the reactive power and working power. When you have a lot of foam (kVAR) in your glass, the lower your working power (kW), which is equivalent to a low power factor.

Figure 1: Glass of soda, active and reactive power analogy

Having a low power factor in the plant presents some disadvantages such as:

- Oversizing of transformers, bus, switches, cables…

- Increasing of the consumption of the plant.

- Increasing of the losses

- Increasing of the voltage drop

- Financial penalties from electrical utility

Power factor can be improved by adding power factor correction capacitors to the main distribution board. This will generate capacitive power that will make decrease consumed reactive power of the plant, therefore the efficiency (PF) of the plant will increase.

Sinusoidal waveform distortion: Harmonics

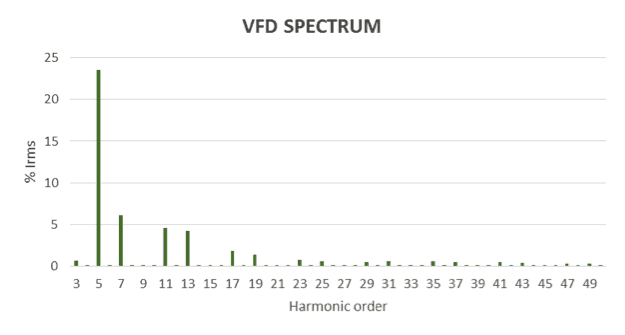

Harmonic distortion is a specific type of perturbation that is associated with the increase in the use of power electronic equipment in industrial plants. In a Cooling Plant, the main source of harmonics are 3-phase nonlinear loads (VFDs, UPS, converters…), where the dominant harmonic orders are 5 th, 7 th, 11 th and 13 th. The mentioned equipment usually have installed six-pulse converters with a harmonic spectrum similar to the one shown below:

Figure 2: 6-pulse VFD Harmonic Distortion Spectrum

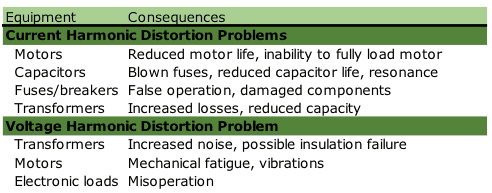

These harmonics distort the line current sinusoidal waveform. Harmonic distortion can cause serious operating problems like unintended faults that involve losses of power supply in the plant. Some of the negative consequences that harmonics can have on typical equipment found in a Cooling Plant are summarized in below table:

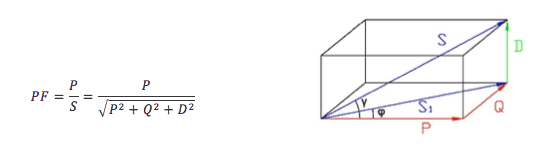

Also, high levels of harmonic distortion imply a decrease of the power factor. This is due to a new component of power as consequence of harmonic currents, named Harmonic Distortion power (D). Therefore all the inconveniences related to a low power factor seen previously also need to be considered. New power factor is defined as per below formula:

Figure 3: Power diagram

In addition to the mentioned disadvantages, more and more utilities are demanding their customers more strict requirements related to harmonic distortion. IEEE Standard 519-1992, IEEE Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems, represents the most recent effort to establish a standard level of acceptable harmonic distortion levels on a power system. End users must limit the harmonic currents injected onto the power system and the utility must control the harmonic voltage distortion. In order to comply with harmonic distortion requirements, some of the solutions shown below can be applied:

- Passive filters: installed in series with nonlinear loads to absorb specific harmonic currents generated.

- Active filters: installed in parallel with nonlinear loads to inject a counter phase current to harmonics current in our plant.

- Install more efficient converters with lower harmonics contents (12-pulse, 18-pulse…)

As a summary, improving the power quality of a Cooling Plant involves the following benefits:

- Decrease of the plant consumption

- Decreaseof the losses

- Decrease of the voltage drop

- Avoid financial penalties incurred through non-fulfillment of contract related to power quality

- Prevent damages to another electrical and electronic equipment

- Prevent unintended trips of electrical protections, avoiding costly plant outages

- Reduce heating of electrical equipment, increasing his life cycle

- Avoid unnecessary oversizing of electrical equipment (Transformers, cables….)

Reduce risks with the appropriate design

As it has been shown above, having a low power quality in the plant can involve several technical and economical inconveniences. Also the standards and utility requirements are becoming more demanding, therefore during the design stage of the project this issue must be studied deeply in order to find the optimal solution for the specific plant. If you need expert’s advice at this point, don’t hesitate to contact ARANER. We will be pleased to help you!