Did you know that increasing the inlet temperature of a gas turbine can decrease power loss by as much as 30 %? That is why turbine inlet temperature increase of a gas turbine is such a popular practice today. Even systems that initially did not have the cooling components are considering installing them to stay in touch with power demands. Achieving a cooling system without necessary investment in a new unit is such a cost-effective approach. It is possible for turbine-based power plant to enhance its capacity by up to 30 %. ARANER has been on the frontline developing turbine air inlet cooling solutions, particularly chillers, to make turbines more efficient.

Why Use these Technologies

The technique of cooling turbine inlet air goes by many names including turbine inlet cooling (TIC) and turbine inlet air-cooling (TIAC). Opponents of TIAC solutions cite high power consumption. However, you only need to look at the level of power enhancement the systems introduce in a power plant to disregard such negative views. The net power gain may depend on many turbine and ambient factors, but the bottom-line is that power improvement is usually immense. If you are looking to install such a system, here are your main options.

1. Chiller Technology

Chiller systems cool air indirectly using a cooling fluid. Specifically, the air goes through cold extended surface heat exchangers where humidity condensation takes place. The system removes the condensate droplets by directing them to pans at the base. Most of the condensate droplets are removed this way, but to ensure complete dryness, the air must pass through a mist eliminator unit. Chiller technology comes in the form of either vapor absorption or vapor compression. A vapor absorption chiller uses thermal energy to power its cooling system. Despite its low coefficient of performance, this system is cost effective because it relies on waste heat. When it comes to vapor compression chiller, the system is powered by a small portion of the extra electricity produced. Have you ever wondered why chilling systems are so popular for humid and hot climates? First, this technology is able to cool the air below the wet bulb temperature, which means it can produce more power. In addition, some of these TIAC systems can operate without water consumption. Perhaps the most popular chilled inlet air-cooling project that ARANER has ever undertaken is the TESTIAC system at Dewa L1 station in UAE’s Jebel Ali Power Plant. The benefit of this solution is twofold: it augments power and increases efficiency of three Frame 9 gas turbines. Achieving a turbine inlet temperature of 20° degrees is not a joke in an environment where the ambient temperature is around 50° and humidity is extreme. ARANER has used its immense expertise and state-of-the-art technology to overcome this and other challenges in the implementation of the project.

Jebel Ali Power Plant

2. Evaporative Cooling

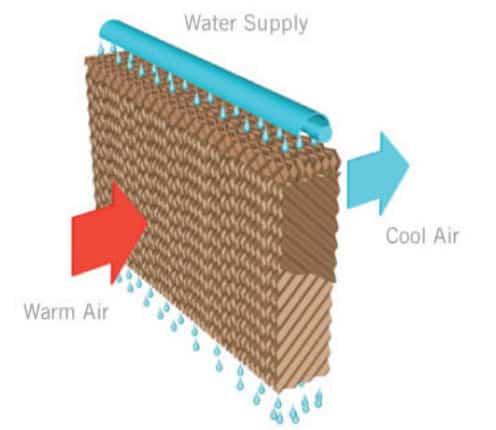

This is probably the most natural cooling process you will ever find. As demonstrated in Fig. 2, this method is all about exposing warm air to water to achieve a temperature drop. Warm air passes through a medium that holds air and exposes it to a large surface area. At the same time, the warm air is exposed to cold air, leading to the formation of cool humid air. This type of inlet air cooling technology is suitable for hot and dry ambient conditions. One reason this method is also preferable is its ease of installation and operation. However, the drawbacks of the evaporative coolers are the low performance and the water consumption.

Simple Demonstration of Evaporative Cooling

3. Fogging

The basic idea of fogging is to mix the inlet air with very fine droplets of water. Because of the exposure to water and the sensitivity of the compressor, a moisture eliminator is a critical component of the system. Because of varied ambient condition needs, these systems come in different designs. This method is low cost, but it comes with several drawbacks, including limitation of cooling water up to wet bulb temperature, blade erosion and overreliance, changes in relative humidity and very high water consumption.

Our Conclusion

There are many technologies to decrease turbine inlet temperature as illustrated here. Each of them has its limitations and advantages. If you are planning to install a turbine inlet air cooling system in your power plant, you might want to research enough and consult an experienced solution provider such as ARANER. There is no better way to maximize turbine output and efficiency for your power plant. Contact us for further information.