It is very rare not to find a heat exchanger in a modern industrial plant. The heat exchangers are so critical to the plant’s operations that they may even determine the overall energy efficiency. Designing a good heat exchanger encompasses maintainability and types of fluids used, but we will try to focus on types of heat exchangers for now. Heat exchanger technology is as old as the duration that man has been using ovens and pots. To recap the principle of heat exchange, we need to look at the three methods of heat transfer namely radiation, conduction and convection. From the pot in those years to today’s advanced heat exchangers, the technology has undergone incredible transformation over the years. We already have a plate and frame heat exchangers weighing it at more than 400 tons. To move such a machine would require a jumbo jet or a powerful crane. Some estimates predict that the heat exchanger market will amount to 19.9 Billion USD by 2026.

What is a heat exchenger?

A heat exchanger is simply equipment that transfers heat from one medium to another. It could be between a fluid and solid particulates, between a fluid and a solid surface or between fluids. Even as the magnitude and complexity of heat exchangers changes, you must keep in mind that their basic configuration remains pretty the same.

Types of heat exchangers

There are different ways of classifying heat exchangers:

- Classification according to heat transfer mechanism

- Single- phase convection on both sides

- Single- phase convection on one side, two- phase convection on other side

- Two- phase convection on both sides

- Combined convection and radiative heat transfer

- Classification according to number of fluids involved

- Two – fluids

- Three – fluids

- N – fluids (N > 3)

- Classification according to design/construction features

- Shell-and-tube: Cross flow to tubes or Parallel flow to tubes

- Spiral Tube

- Pipe coils

- Classification According To Flow Methods

- Single – pass

- Multi-pass

- Shell-and-tube

- Plate

Due to these many classifications, we will choose one of them and run away with it. In the industry, we find it more relevant to base the classification on flow method. Of course, this is not to downplay the relevance of the other classifications.

Shell-And-Tube Heat Exchanger

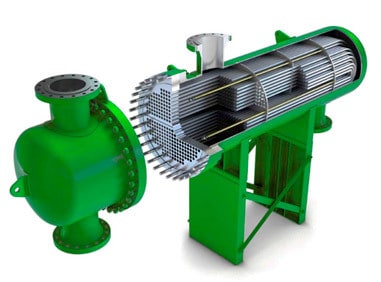

Fig 1: Shell and Tube Heat Exchanger

This heat exchanger gets its name from its two main components - a cylindrical shell with round tubes mounted inside it. Other components of this heat exchanger are:

- Expansion joint

- Spacers & tie rods

- Baffles

- Tube sheets

- Pass partition plates

This is easily the most popular heat exchanger in the industry today. It features a very flexible design, allowing a wide range of temperatures and pressures. Furthermore, the device can be made from a wide array of metallic and non-metallic materials. Design pressures and temperatures can be as high as 6,000 psi and 800̊C respectively. Compared to other types of heat exchangers, the shell and tube heat exchanger is sturdier in construction. That means it will withstand process and physical abuse for longer. Unfortunately, it is economic and efficiency shortcomings make it a poor fit for applications where highly viscous fluids are used. It may also not suit heat recovery applications for the same reasons. The two main categorizations of this type of heat exchanger are:

- Those found in the petrochemical industry

- Those found in the power industry

Plate Heat Exchanger

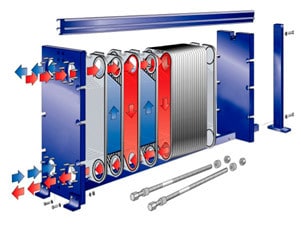

Fig 2: Plate Heat Exchanger

The main components of most heat exchangers are cooled or heated pipes, but the plated variety is a bit different. In place of pipes, this device comes with alternating chambers, and between them are metal plates. Since the plates occupy a small area but create a large surface area, this heat exchanger tends to be compact. The design also supports a wide range of applications. Maintenance is easy thanks to the removable plates. Another plus of this heat exchanger the accurate temperature control it offers.

Enhancing Heat Exchanger Efficiency

If you are using thermal performance to measure the efficiency of a heat exchanger, you can pursue a number of approaches to enhance efficiency. We summarize them using three areas as outlined below.

-

Installation

Installation of the heat exchanger matters a lot. It is important to follow the manufacturer’s guidelines. In most cases, the fluids within the device should flow in opposing directions regardless of the type of heat exchanger in focus. -

Flow Rate

Flow rate applies for primary and secondary sides of the equipment. The interaction between flow rate and mass is interesting. Therefore, it is important to contact ARANER specialist for the best balance of these two components. -

Temperature Differential

The efficiency of the heat exchanger also depends on the temperature difference between coolant and hot fluid. Of course, the coolant should be perpetually cooler than the fluid. The colder the coolant, the more heat it will take from the hot fluid.

Countering fouling in heat exchangers and other related problems starts with knowing the basics of the equipment. Our review of heat exchanger technology has taken us to definition, classifications and a bit of maintenance. You can be sure there is so much to regarding these irreplaceable industrial devices. Do not hesitate to contact the team with any comments or questions.