In climates with high ambient temperatures the power output and efficiency of gas turbines used by oil companies are both reduced. Lower inlet air temperatures significantly increase power production and improve efficiency during periods of warm weather, whether the gas turbines are used for electrical power generation or mechanical drive. This was the case of Aramco, which is well known as the biggest Oil & Gas Company in the world, with the largest crude oil reserves and the highest daily oil production. In 2013, Aramco continued with its expansion developing three Independent Power Projects comprised of three greenfield gas-fired power plants in Arabia. Over the course of the expansion they found it necessary to improve the efficiency and deliver a power increase to all of the new gas turbines. At ARANER, we supplied the Turbine Inlet Air Cooling systems (TIAC) for these projects. By cooling down the Gas Turbine Inlet Air, ARANER improved the turbine efficiency for each unit and increased its power output. Saudi Aramco obtained more than 146.16 MW of extra power thanks to TIAC systems with a very low capital cost. We designed and fabricated the most suitable and adequate equipment based on different scenarios according to individual site conditions. You can get more information on this post or by downloading for free the Saudi Aramco Case Study.

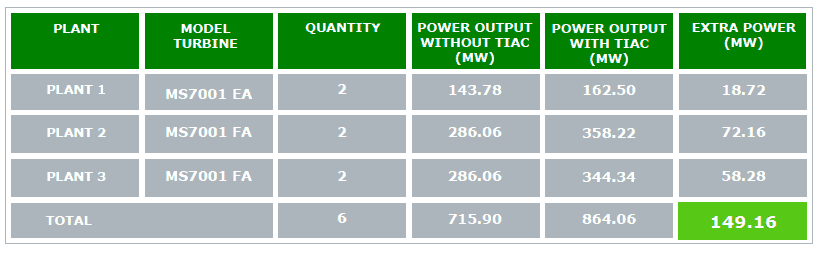

TIAC solution final results

Turbine Inlet Air Cooling is a proven power augmentation technology . With TIAC systems, the air is cooled down to 15º C (or close to 15º C) so the gas turbine will be working close to design conditions producing the maximum power. The conclusion is that more than 149.16 MW of extra power are recovered thanks to the TIAC system with a very low capital cost . Although for this case the increase in power output is only 21 % because of the project requirements and parameters, for some cases and especially for aero derivative gas turbine the power recovered can be up to 40 %. As a result, the project has surpassed owner expectations not only because of the extra power but also because of the efficiency increase that is achieved thanks to the Turbine Inlet Air Cooling.

About ARANER’s TIAC solution

Turbine Inlet Air Cooling (TIAC) is a group of technologies and techniques whose objective is cooling down the intake air of the gas turbine and ultimately power output augmentation. This technology is widely used in climates with high ambient temperatures that usually coincide with on-peak power demand. With the modular solution, site works are reduced to the minimum possible. The TIAC modular solution leaves the factory in a state of being ready to start the operation. All that is left to carry out is the connection to the existing utilities. For this purpose, and because of the extreme site conditions found in the plant location (proximity to the sea and surrounding industrial area), ARANER applied a special coating for the Inlet Air Heat Exchangers based on phenolic resin which guarantee a long service life with no deterioration or corrosion. Are you interested in our solutions? Contact us for further information.