District heating using electrical driven Heat Pumps is one of the cutting-edge technologies that is being implemented in the market as a sustainable energy solution for heating our present and future and its use for large scale district heating networks is increasing more and more.

There are several Heat Pumps technologies that we discussed in previous articles but today we want to review the best refrigerant for Heat Pumps that are present in the market.

Background on refrigerants

Over the last decades legislation has prohibited the use of ozone-depleting CFC refrigerants, and these were replaced with HFC refrigerants. In more recent times it has been realized that GWP factor is equally damaging to the atmosphere so legislation has provided limitations with regards to the GWP value, the manufacture, and usage of the refrigerants. Current legislation is covered by the F-Gas Regulations and Kigali amendment to the Montreal protocol, which intends to limit the use of GWP refrigerants and establish a phase down for those which exceed the acceptable values.

Nowadays, the refrigerants R134a, R404a/R407a or R410A are widely used in the industrial refrigeration chillers and heat pump market. This HFC has zero ODP, non-flammable, very low toxicity, non-corrosiveness and good thermodynamic properties, but there is a problem, its high GWP. But what are the alternatives? HFOs, “natural refrigerants”, low GWP mixed blends? It is sometimes difficult to get at the truth from the conflicting claims and vested interests of the chemical manufacturers and “green” groups.

This brings us to the current situation, where the industry is looking for proper replacements for the existing and new HVAC&R installations and there is a huge portfolio of best refrigerants for heat pumps with low GWP, HFC, HFO, blends and Naturals refrigerants including hydrocarbons. Let’s see which parameters shall be evaluated to select the proper one for a heat pump project.

Appropriate selection & parameters for Heat Pump refrigerant

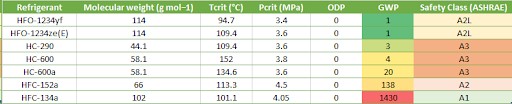

The best refrigerant for heat pump must be non-corrosive, non-toxic, non-flammable, with no ozone depletion and global warming potential, as well as easy to produce.

Focusing on the refrigerant gas selection for an industrial Heat pump system, one of the most relevant parameters is the critical point. The critical point is related to the desired temperature to be achieved in the heat sink. Many refrigerants such as R134a, R410A, R32 or R1234yf have the critical point below or around 100ºC, so that means that the maximum temperature on the heat source could be 70-85ºC. Thus, other refrigerants such R1234ze or R152a have the critical point above 110ºC, making it possible to reach up to 95ºC of hot water supply in a heat pump system.

Another aspect to have in consideration is the price per kg of gas. In large installations with several large HP systems the refrigerant load can reach several tons. While the price of the natural refrigerants or pure gases such R717, R744, R600 or R152a are low (1-5USD/kg) the same could rises significantly (up to 100USD/kg) in new proprietary gases such R1233zd, R1234ze or R1234yf. This difference is impacting directly on the total installation cost and shall be considered. Also taxation of each gas shall be considered, that generally is higher as higher is the GWP value.

Flammability is a key aspect; considering many of the new proposed refrigerant alternatives, we found that many of them are slightly flammable. Seems that is difficult or impossible to find a low GWP alternatives without being flammable, mainly formed with ethane or propane particles, and seems that the industry and regulations are becoming friendly with A2/A2L refrigerant in the meantime there is no non-flammable alternative without affecting other parameters of the equation such performance or low GWP.

Finally, it is important to have in consideration the differences between the direct GWP and indirect GWP. It is observed that many replacements of the actual refrigerants have lower efficiency than the actuals. This is directly translated into higher operation cost and electricity consumption to reach the desired amount of heat and might be indirectly translated into a higher CO2 emissions, depending on the technology of the electricity source, which nowadays is coming largely from fossil fuels. It is important to realize that the direct GWP of a refrigerant only would produce the damage in the environment if the same is released to the ambient. Here the importance of having a trained personnel to handle the heat pump and its maintenance, avoiding any leak on the system.

Conclusion

Balance between important aspects such as flammability, direct GWP and indirect GWP (related to the efficiency), thermodynamic capacity, working pressure, safety, sustainability, cost or even intellectual property are essential to determine the best refrigerant for heat pumps.

The wide-ranging of alternatives makes it necessary to study each case to determine the best solution. For that and other reasons, Araner is the ideal partner as a heat pump and district energy expert, providing for each case the proper solution thanks to our widely experienced and state of the art tailor-made solutions.