District Cooling (DC) systems generate chilled water at a central plant and pipe the water to area buildings and the overall district to provide air conditioning. Centrally-located facilities should be custom-designed to adequately meet the specific cooling loads required by the premises served. Since the equipment for District Cooling is in a central location, the buildings served may be able to take advantage of additional usable floor space, as there is no need for a large mechanical room. While District Cooling systems may be operated using electricity from the public grid, ARANER is able to design systems with practically null dependence on electricity such as absorption chillers fed by waste heat from the plant process or chillers driven by diesel/gas engines, or gas turbines. The solution based on absorption chillers are closed systems that rely on chemical and physical principals to chill water, rather than mechanics. Absorption chillers offer lower operating costs and are generally as reliable as mechanical compression chillers, meaning low maintenance is required. In addition to the potential for reduced maintenance costs, District Cooling systems operate at a higher thermal efficiency as a result of the economy of scale, which offers the potential for additional cost savings over the life of the system. At ARANER, we create systems that take advantage of an existing heat source or locally sourced fuels to provide long-term cost savings. Below, we explain how tailor-made DC systems work to ensure the electricity supply, the different methods used, and the environmental and cost benefits provided by these systems.

What happens when the electric goes out?

Figure 1: A complete power outage in a major city

Traditional cooling systems commonly rely on the local power grid to provide energy, and by nature, are highly susceptible to power outages and brownouts (defined as a partial or temporary reduction in system voltage or capacity). The ARANER team can design a District Cooling system that uses a non-electric powered heat source, and therefore it will not be vulnerable to these outage events. These systems continue to provide enough cooling, heating, and hot water to the served buildings during power outages by providing an alternative source of electricity through cogeneration or trigeneration.

Cogerenation and Trigeneration

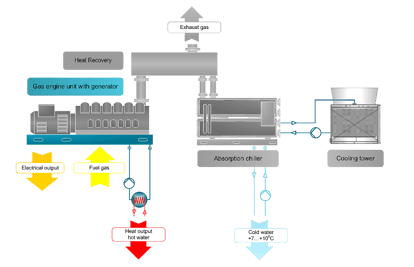

Cogeneration is the production of electricity and heat using a single source, and similarly, trigeneration refers to the generation of power, heating, and cooling from a single heat source. Taking advantage of cogeneration or trigeneration results in significantly less wasted energy and provides even higher efficiencies than district systems alone. These energy savings result in the potential for future cost-savings on cooling, heating, and electricity for the district.

Combined Heat & Power Systems

Systems that use cogeneration or trigeneration are often referred to as combined heat and power (CHP) systems. CHP systems are used for continuous cooling, heating, and hot water by providing power to any components of the system which may need it, such as pumps. These systems may also be used to supply back-up power to critical components and lighting systems during outages. A CHP system can be designed to provide redundancy of power to servers, phone systems, and other operations, allowing them to remain functional during an interruption in the traditional electric supply.

Figure 2: Typical Trigeneration Scheme

A CHP system has significant financial and environmental benefits. A CHP system can operate at higher overall efficiencies than traditional power systems. Trigeneration systems are the most efficient method, as the same heat source provides electricity, cooling, heat, hot water, and even steam or hot air (for certain industrial applications). These systems offer the most significant benefits when designed to fit buildings which require a constant supply of electricity, heating, and cooling. CHP systems also offer significantly lower emissions than traditional heating, cooling, and electrical generation systems alone. These systems, as discussed, are designed to incorporate local and renewable resources; examples might include industrial waste heat, geothermal energy, biogas, or solar power. Seas, rivers, and lakes located within reasonable proximity to the district may provide fresh and cooling water. In areas where water availability is a concern, ARANER can design systems tailored to offer no or low water use options, contributing to local water conservation efforts. In addition, ARANER has a wealth of experience in designing tailor-made CHP systems that use cogeneration or trigeneration.

LEED Certification - Leadership in Energy & Environmental Design

Figure 3: LEED certification on a building

LEED, or Leadership in Energy and Environmental Design, is an internationally-recognized rating system that attests to a building’s “green” features. It encourages the design, operation, and maintenance of buildings that use resources efficiently and have a reduced impact on the environment. Factors that are considered include energy and water savings, reduction of carbon emissions, and environmental quality and impact, among others. ARANER designs systems that are eligible for points towards the LEED certification of a building. Since ARANER’s tailor-made District Cooling and CHP systems capture power otherwise lost and use it to generate cooling and heating, they are 75-80% more efficient and reduce fuel use. These are valuable assets towards gaining points for LEED certification. When ARANER designs a CHP system with LEED certification in mind, the system should easily achieve the maximum number of points allowed, putting the building closer to gaining its LEED certification.

Conclusion

When the electricity supply goes out, plant owners and operators need to have a secure and stable District Cooling system that they can rely on. Customized and advanced District Cooling systems, like those provided by ARANER, are able to prevent events like power outages and brownouts from happening by using a non-electric heat source. Furthermore, a DC or CHP system offers benefits like lower capital costs, high efficiency, reduced operations & maintenance costs, and reduced or no dependence upon the grid for electricity. ARANER systems offer many great options to keep buildings comfortable year-round, regardless of the climate, and even when you experience power outages! Our District Cooling systems are custom-designed specifically to meet every facility’s unique needs and come with outstanding service. If you’re working towards a LEED certification, ARANER will design a system to help you achieve it! Get in touch with ARANER and let our design team come up with the perfect solution for your project.