District Cooling plants have become an increasingly popular option to provide cost-effective, efficient cooling to business districts and communities.

In areas where there is a nearby source of naturally-occurring cold water, many of these plants are opting to use water-cooled chillers. Water-cooled chillers, as their name states, use water to remove excess heat from the process water and conduct the heat out of the plant using heat exchangers. In water scarce areas, there is a greater preference for Air-cooled chillers.

District Cooling plants have environmental benefits and, as with any process that involves the transfer of energy, have environmental considerations and concerns.

Environmental Considerations of Chillers for District Cooling

Different chillers vary in their method of operation and, as a result, have different environmental impacts. Consideration of environmental factors during chiller selection includes availability of water, refrigerants, and power consumption.

Water Use

Water and water conservation require careful consideration during chiller selection. The proximity of natural cooling water to the District Cooling plant and local water conservation policies are important considerations during the selection process. Many locations have regulations surrounding the reduction of water consumption, which may impact the selection. The air-cooled chiller, with no water requirement, may receive preference when water conservation requirements are too stringent for a water-cooled chiller. For a use-case of an air-cooled chiller, discover the Abdali Area in Amman, Jordan.

Refrigerants

Figure 1: Ammonia is a common refrigerant used in District Cooling plants

Some chillers may require commercial refrigerants to achieve cooling. These refrigerants contain chemicals that may contribute to global warming. These chemicals absorb infrared light and trap it in the atmosphere, resulting in a slow, persistent increase in temperature. New refrigerants, believed to cause less harm than older refrigerants, are available. These new refrigerants contain chemicals thought to reduce the greenhouse effect and experts consider them less harmful. ARANER uses these new refrigerants as well as natural refrigerants like ammonia and CO2. However, careful consideration of refrigerant use and impacts are crucial when selecting a chiller.

Power Consumption

We often think of power consumption in terms of life cycle costs, but when selecting a chiller, one must also consider the environmental effects. A chiller with a higher power consumption results in additional carbon emissions from the power plant. The assessment for power consumption and carbon emissions must include the chiller and all ancillary equipment, like pumps, for equivalent comparison. ARANER are experts at analysis of this type, to be able to choose the correct system for your unique use.

Benefits of a Water-Cooled Chiller

Using naturally occurring cold water to remove heat is efficient, requiring less electricity than conventional solutions and having no direct carbon emissions. Water-cooled chillers do not require large quantities of chemical refrigerants, which are often required by air-cooled chillers and may harm the earth’s atmosphere. Furthermore, either freshwater or seawater can be used for water-cooled chillers.

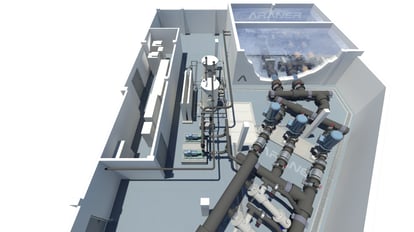

Figure 2: Ayla District Cooling Plant using seawater cooling

Discover the case study on the seawater-cooled Ayla Oasis Resort, where no fresh water was consumed. It is important to note that there is a drastic reduction in electricity when using a water-cooled chiller resulting in reduced carbon emissions from the power plant. Additional opportunities for power savings and a reduction in carbon emissions exist when the water-cooled district cooling plant takes advantage of balancing supply and demand, offering incentives for users who shift their use to times of the lower demand for both cooling and electric. Another complementary solution, which enhance the savings, is the use of a Thermal Energy Storage System. There may be incentives other than the environmental considerations for selecting a water-cooled chiller for your project, including a legal requirement, or incentives from the government or utility provider.

Maintenance and Projected Lifespan for Water-Cooled Chillers

Proper maintenance is essential to the overall efficiency and environmental effect of the cooling plant. A good preventative maintenance program and attentive operators can help to avoid unwanted environmental impacts and keep a plant running for many years. The life of actual equipment varies, typically water-cooled chillers have a lifespan of 10 to 20 years, with some lasting 25 years or more. The underground piping that carries chilled water, both natural and processed, can last up to 100 years with proper maintenance.

Benefits and Maintenance of Air-Cooled Chillers

Despite the benefits of water-cooled chillers, in a water scarce area like many parts of the Middle East, air-cooled chillers are more appropriate. More than that though, by not using water, air chillers avoid high water costs, have no water wastage nor chemicals, and don’t have to deal with water problems in the event of a disaster. Although traditionally thought to be less efficient than water-cooled chillers, they have vastly improved in efficiency and NPLV rating. A final benefit of air-cooled chillers hinges on maintenance. They are almost completely maintenance free except for the occasional cleaning of condenser coils, which can be important in polluted environments to avoid fouling and increased power consumption.

Conclusion

Water-cooled chillers have tremendous advantages for a District Cooling plant near a natural water source. These chillers offer tremendous efficiency and can considerably lower the potential CO 2 emissions from the direct cooling facility. If there are water regulations in your area, take advantage of the increased efficiency and low maintenance of air-cooled chillers, which tend to even more environmentally-friendly than water chillers. The professionals at ARANER can help you determine if a water or air-cooled chiller is right for your project and design a plant that has the best technologies for both efficiency and reduced CO 2 emissions. Proper design, installation, and maintenance are imperative to getting the expected performance. ARANER has significant experience with air and water-cooled chillers and can help you every step of the way.