The power generation industry is leaning towards combined cycles, which are in high demand for their minimal delivery time and higher efficiency. Enhanced efficiency is beneficial for both countering the greenhouse effect and reducing fuel expenses. One of the most important components in combined cycle and cogeneration power plants is the Heat Recovery Steam Generator (HRSG), which is sandwiched between the gas turbine and the steam turbine. In this article, we highlight the basics of the HRSG and its importance in the industry. Consultants, plant engineers and generally anyone involved in projects will find this information relevant when making key decisions regarding the system.

Where the HRSG is Used

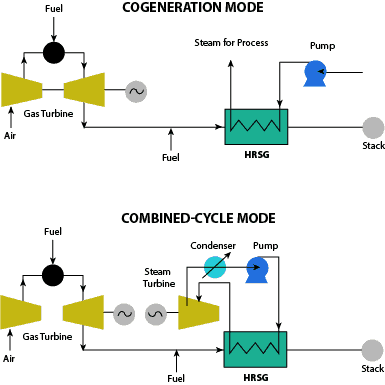

The HRSG can be used to drive a steam turbine for power generation, or to generate steam for factory processes or district heating. When used for cogeneration purposes, the HRSG-produced steam is for process applications. In the combined cycle mode, the steam produced goes to a steam turbine generator for power generation. The two modes are demonstrated in the figure below.

Fig 1: Cogeneration Mode and Combined Cycle Mode

When used in cogeneration, these devices offer environmental and economic benefits. They also enhance overall plant efficiency to as much as 90%. In combined cycles, the HRSG has been seen to enhance efficiency of the combined system to as much as 60%.

Design and Operation

Even with the numerous brands of HRSG in the market, the basic design has remained largely the same. The generator is simply a group of tubes placed within an exhaust gas path. The exhaust gases that heat the water-containing tubes are at a temperature of up to 650ºC. Heat absorption from the flue gases is often through convection method, but some designs use convection or radiation. To produce steam, the water is held at a temperature of 200ºC and extremely high pressures. Essentially, the HRSG is composed of several heat exchangers making it a large heat exchanger. The heat exchanger tubes are set in different modules or sections, popularly known as:

- Economizer

- Evaporator

- Super-heater

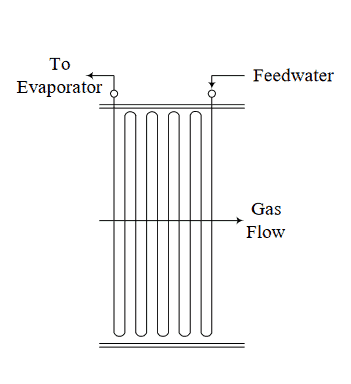

Economizer

The function of the economizer is to preheat the feed-water and replace the steam removed. Once the water approaches the boiling point (saturation temperature), it supplied to the steam drum.

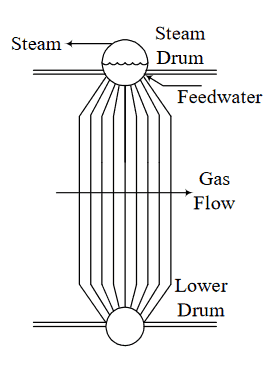

Evaporator

The evaporator refers to the section where the water in the tubes turns into steam from the heat of the gas turbine exhaust.

As shown in the figure above, water/steam moves from the lower drum to the upper drum (steam drum). Steam leaves the upper drum via the steam separating equipment.

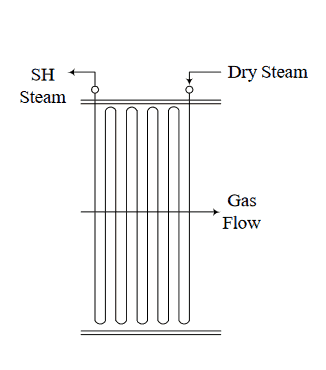

Superheaters/Reheaters

When saturated steam leaves the evaporator, it goes to the superheaters/reheaters where it is turned into dry steam. This is important because steam turbines run on dry steam. The movement of the steam through this section is as showed in the diagram below.

Classification of HRSGs

Classification is based on operation, application, or design. This gives several types of these generators as described below.

⦁ Vertical And Horizontal

Depending on design or construction, HRSGs can be either vertical or horizontal. Vertical generators have vertically flowing gas and horizontally placed coils. For horizontal types, gas flows horizontally across vertical coils. While the overall cost of these designs is almost the same, client’s preference may be advised by footprint area, maintenance, structural requirements and other factors that may vary,

⦁ Fired and Unfired

The second way of classifying HRSGs is to consider the heat input. Conventionally, HRSGs rely on exhaust heat alone. However, this becomes a challenge at part loads. Ambient conditions also affect turbine performance. That is why supplemental firing is often part of the system.

⦁ Single and Multi Pressure

Basing the classification on pressure level gives these two types of generators. With one steam drum, single-pressure HRSGs generate steam at a single pressure level. This is unlike the multi pressure type that features multi pressure circuits.

Conclusion

There is a reason why a lot of focus is on combined cycle and cogeneration power plants- the overall efficiency of the plant is increased in both cases. Whether used for district applications, process heating or electricity production, HRSG offers value for money for the owner. Furthermore, you can always enhance the efficiency of your HRSG in ways that we will explain in an upcoming post. Keep reading our posts.