The steam turbine has been a crucial component in processes related to the generation of energy. As society is more and more involved in looking at how energy is created and the sustainability and efficiency of the process, addressing the question of ‘what is a steam turbine’ and how this technology can be improved becomes essential.

Let us guide you through a quick but insightful guide into the steam turbine: what this component is, its functions and the developments in the steam turbine that are facilitating the efficiency improvements.

What is a steam turbine? A definition

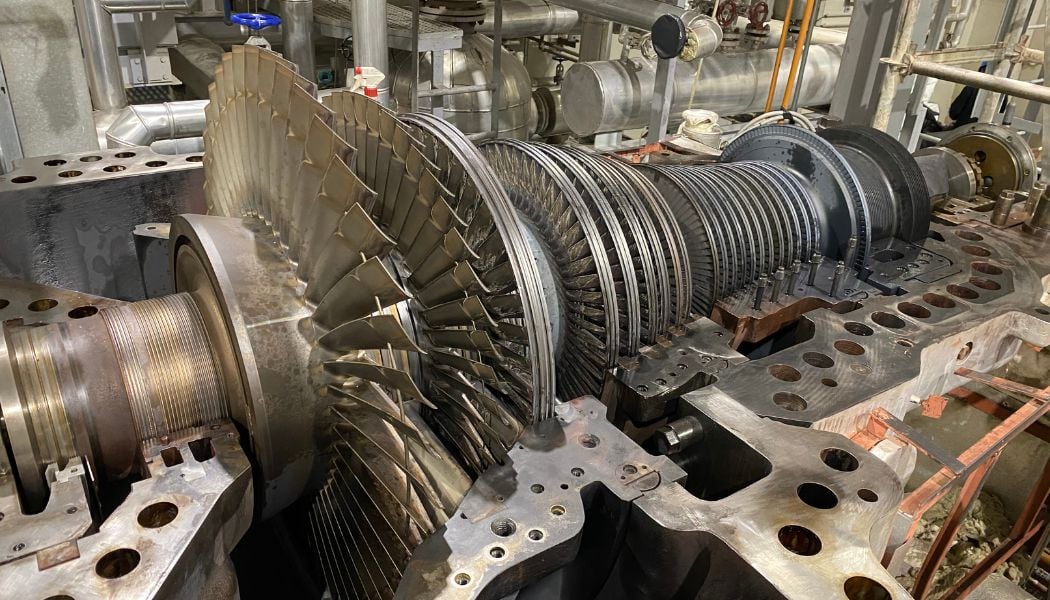

The steam turbine is a machine that, categorized as a form of heat engine, is able to extract thermal energy from steam and convert it into rotary motions.

The modern version of the steam turbine was invented by Charles Parsons in 1884 and is guided by the principles of thermodynamic efficiency, focusing on the different stages of steam expansion.

What is the function of a steam turbine?

The steam turbine has become a key component in the generation of energy. As mentioned above, the steam turbine converts steam energy in steam into rotary motion. Coupled to a generator, this then is converted into electricity.

Steam turbines can be found in key energy generation processes, including thermal power stations and district cooling schemes.

The prevalence of this type of energy generation can be measured by looking at its market value prospects: the Steam Turbine Market Report by Global News Wire forecasts a compound annual growth rate (CAGR) of 4.41% for this market from 2022 to 2026.

How does a steam turbine work?

- The steam turbine employs a heat source to warm up water and convert it into steam. These heat sources vary from gas, coal, to nuclear or solar power

- Water molecules expand thanks to this process

- Steam is then passed through the turbine’s blades, which turn the thermal energy of steam into kinetic energy by rotating. The blades are able to control steam’s speed, direction and pressure. Following a structure where only small increments are made gradually, this means turbines can reduce steam’s pressure and thus improve the electrical output and efficiencies

- The steam turbine is connected to a generator, in charge of producing an electric current

Efficiency in steam turbine

Generally speaking, the term turbine efficiency describes the ratio of electrical output that is achieved in comparison to the required heat source input. In a context of rising heat source prices (such as natural gas), as well as an increased focus on sustainability, the efficiency of steam turbines cannot be underestimated.

In short, better turbine efficiency reduces operational costs and presents a lower environmental impact.

Having a clear understanding of the turbine efficiency formula remains an essential tool for operators looking to reduce fuel consumption and profitability options. Considering fuel costs are beyond any operator’s control, taking a look at turbine efficiencies remains key.

Heat rates are also a valuable insight for operators. This metric connects power plants to thermal efficiency values, and compares the amount of heat capable of generating 1 kilowatt-hour (kWh) of power. It is inversely proportional to power plant efficiency, and is related to three key concepts: Electric Power Output, Operating Conditions and Plant Design.

Heat rate improvements can take many shapes and forms, the focus on steam turbine performance being one of them. Again, this strategy looks into the power output of the turbine compared to the used resources to measure efficiency.

Key developments in this area include incorporating Heat Recovery Steam Generator (HRSG) structures and Turbine Inlet Air Cooling (TIAC) solutions mixed with Thermal Energy Storage (TES), the latter being particularly crucial in locations with extreme weather conditions.

Types of steam turbines

There are different criteria that can guide the classifications of steam turbines. These include construction techniques, sizes or working pressures, among others. The following include two of the main classifications:

Impulse vs. reaction turbines

- Impulse turbines operate on the basis of superheated steam sent through the turbine blades at high velocities, generating a rotating motion and kinetic energy in the turbine. This type of turbine allows for large pressure drops per single stages, so that a smaller number of stages can be considered. This, in turn, is favorable for improving efficiency at low speeds.

- The operation of reaction turbines relies on steam passing from fixed blades to the shaped rotor blade nozzles, which causes the turbine shaft to react and rotate. This equipment, invented by Sir Charles Parsons and also known as the Parsons turbine, works with the steam having expanded in previous stages through the fixed nozzle. This converts potential energy to kinetic energy, as the steam collisions with the blades and experiences further expansion, which as a result causes rotors to turn. As such, pressure drops take place in different stages because pressure drops per stage are lower. As a result, the steam that reaches the turbine presents a lower pressure and temperature, so that the best efficiency can be achieved. Appart from a higher efficiency, another key difference with impulse turbines is that reaction equipment will typically need a higher number of blade rows to generate the same thermal energy output, a characteristic that has an impact on the bigger size and weight of reaction turbines.

Condensing vs. noncondensing Turbines

- Condensing turbines operate by condensing steam to achieve pressures below atmospheric values. The goal is to boost the amount of energy that can be obtained.

- Noncondensing turbines, on the other hand, operate with steam above atmospheric pressure. This means the steam can then be used for heating before becoming part of the water boiler.

The goal of our brief guide was to provide a clear answer to ‘what is a steam turbine’ and describe in short what the function of this equipment is and how it’s taking the central stage in several modern applications.

This includes district energy solutions, an approach to heating and cooling that is facilitating the move towards sustainability and efficiency.

From our perspective as experts in pioneering energy solutions, at ARANER we’re at the forefront of developing efficient district heating equipment that incorporates the latest developments in steam turbine technologies.

Download our free ebook about district energy to learn more about the role of steam turbines in this kind of energy generation initiatives or get in touch with us to speak to our team.