Using hydrogen for heating has been at the center of a number of initiatives which are looking for decarbonizing alternatives to fossil fuels in heating.

While today 95% of hydrogen is produced using hydrocarbon methods (either fossil fuels or biomass), the promising methods of hydrogen electrolysis lie at the heart of many important sustainability efforts. In fact, using hydrogen for heating is now becoming one of the most crucial in terms of renewable heating solutions.

What if the waste heat produced by hydrogen electrolysis (which amounts to between 30 to 20% of electricity used in the process) could be harnessed and converted into heating through district energy initiatives? Mejor poner un link a algun post sobre Heat Pumps Keep reading to find out.

How does hydrogen for heating work

When speaking about hydrogen for heating, the conventional approach has turned to burning hydrogen gas, which usually is produced using fossil fuels.

While this method is responsible for significant green gas emissions, the perspective of employing waste heat from hydrogen electrolysis represents a much more revolutionary approach.

Hydrogen electrolysis is the process of obtaining hydrogen by using electricity to split water (H2O) into its constituent elements, hydrogen (H2) and oxygen (O2). This method has been hailed as a clean and sustainable energy source (especially when the electricity used is generated from renewable sources) that has important implications in fields such as transportation or industrial processes.

However, hydrogen electrolysis is faced with a challenge: the energy losses it creates. This is because, in the process, between 60 to 70% of electricity input is transferred to the product, while the rest of energy is dissipated into heat.

This is precisely where district energy and heat pumps come in, facilitating the reuse of such heat and effectively generating clean, sustainable hydrogen for heating projects.

While this residual heat presents low-to-mid temperature ranges, the use of industrial heat pumps could enable its reutilization by upgrading it and redistributing it through district heating systems.

This possibility is no longer just a potential: it’s being implemented in pioneer projects in Denmark and other locations, while it’s said to be able to cover 12% of Austria’s current District Heating demand and up to 4% of Europe’s demand for heat below 100 °C (Böhm et al.).

The benefits of hydrogen for heating via hydrogen electrolysis and district heating

The first obvious advantage of embracing hydrogen for heating via an hydrogen electrolysis route is an increased efficiency.

Current data shows that an electrolyzer and heat pump solution can increase energy utilization to ranges between 75% to 96%. This is particularly true if highly-efficient heat pumps are employed, so that their design also results in machines with lower energy usage. All in all, this solution increases the use of energy in hydrogen electrolysis processes, thus also making green hydrogen production a more attractive prospect.

This adds up to district heating’s own claims for impressive efficiency. A centralized approach to heating production and distribution, district heating has been hailed as a marker for extraordinary efficiency when paired up with the right industrial heat pumps.

Additionally, this approach to using hydrogen for heating also represents a step forward in reducing heating plants’ footprint. It’s in fact yet another way to integrate renewable energies into heat production, incorporating a flexible and reliable source that moves towards effective decarbonization.

What the future of hydrogen for heating looks like

As we’ve seen above, hydrogen electrolysis can greatly benefit from being paired up with district heating initiatives. Both of them thus represent two fundamental pillars and good practices for what efficient, sustainable cities of the present and future look like.

By building synergies between power-to-hydrogen and district heating, there are countless opportunities for leading in initiatives that seek to decarbonize heating.

At the same time, both hydrogen electrolysis and district heating initiatives are being promoted by international institutions and governmental funds. As the world moves to achieve climate goals, the development of efficient, sustainable and synergic projects such as pairing up hydrogen electrolysis and heat pumps will continue to be favored. Such is the case of the hydrogen strategy in the European Union (which aims at implementing up to 40 GW electrolyzer capacities in the EU in the coming years) and the institution’s favorable approach to efficient district heating initiatives.

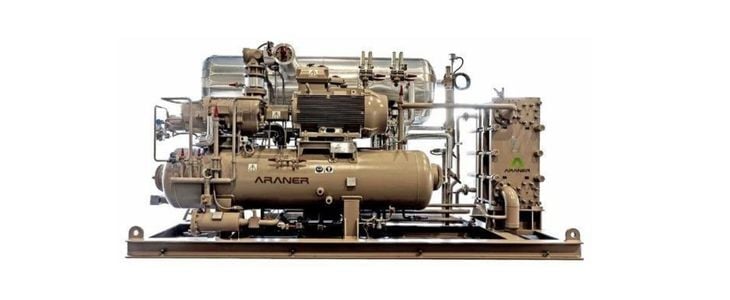

At Araner, we’re committed to putting our heating engineering expertise to work in decarbonizing initiatives. This is why we stand at the center of projects aiming at pioneering efforts in using hydrogen for heating in a sustainable manner. As such, our district heating solutions remain a leading initiative for advanced projects looking to take hydrogen electrolysis to the next level by exploiting its potential for heating.

Get in touch with us and speak to our team about this possibility.