Heat pump fundamentals

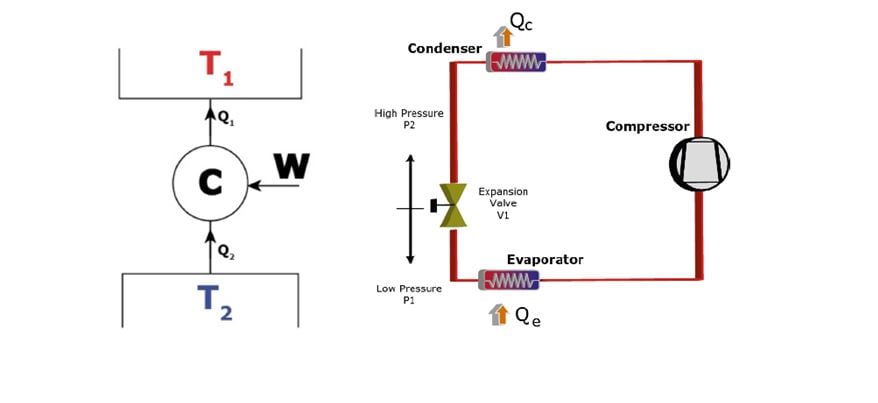

A heat pump is a machine used for producing heating energy. It needs an electrical input and another system to extract heat from. It is a versatile solution for heating because most often those sources are available. The heat pump cycle principle consists of transferring heat from a cold system (T2) to a hot system (T1), following the Reversed Carnot Cycle. Since this transfer of heat goes against the natural energy flow according to the Laws of Thermodynamics, work should be applied on a third system, consisting of a fluid changing its phase between liquid and gas. This fluid receives the name of refrigerant. The refrigerant in the evaporator has a lower temperature than the cold system (T2), so energy is transferred from the cold system to the refrigerant. The refrigerant changes its phase from liquid to gas, since it is absorbing heat. Then the refrigerant is compressed; the rise of pressure causes the refrigerant temperature to rise above the hot system temperature (T1). Therefore, as the refrigerant enters the condenser, energy is transferred from the refrigerant to the hot system. The refrigerant changes its phase from gas to a liquid since it is releasing heat. Afterward, the pressure is dropped with an expansion valve, making the temperature of the refrigerant lower than the cold system (T2) just like at the beginning of the cycle, to go inside the evaporator again. As stated before, the result is that heat flows in the opposite direction as it would naturally do; that means from a cold system into a hot system. Depending on the application of the machine, the attention on temperature controlling will be focused on one of the heat exchangers (evaporator or condenser):

- When the purpose is producing heat, the temperature is controlled in the condenser.

- When the purpose is to produce cold, the temperature is controlled in the evaporator. In this case, the machine receives the name of the chiller, as it is a more suitable name regarding its application.

Fig 1. Heat Pump Cycle

Heat pump components

The heat pumps can use diverse technologies, depending on the application and the particular project constraints. Also, the refrigerant selection plays an important role in the technology and the materials used. The compression technology is very important, as it is where work is supplied to the refrigeration cycle, in the form of pressure increment. The technology used for industrial solutions may be screw or centrifugal.

Screw compression is a positive displacement compression. The principle is to reduce the volume of the chamber where the gas is contained, resulting in an increment of pressure. When the pressure reaches the desired value, the gas is discharged into the system.

Centrifugal compression is a dynamic compression. The principle is to increase the speed of the gas particles, increasing the kinetic energy. This kinetic energy is transformed into static pressure when the gas is discharged into the system. The centrifugal technology is normally used for satisfying higher heating loads. Regarding the heat transfer, the heat exchanger in the condenser and evaporator may be plates or shells & tubes.

Heat source (cold system)

The heat is dragged from a cold system, therefore this cold system is often referred to as heat source. The heat is transferred from this system to the heat pump evaporator, where the refrigerant changes its phase from liquid to gas. The cold system varies depending on the project constraints. This conditions the evaporation technology. The ambient air is frequently used as a heat source. In this case, frosting can occur with low evaporation temperatures depending on the weather conditions, causing the loss of heat transference capacity of the heat exchanger. That implies the performance of defrost cycles. A fluid coming from another process can also be used as a heat source when lowering its temperature does not affect the process that it serves, just like the considered “waste” products of an industrial process. The recycling of waste energy usually supposes the enhancement of the global plant efficiency. The use of geothermal energy as a heat source may be another interesting possibility when implementing the heat pump solution. Underground water has usually a stable temperature, often higher than the ambient temperature, as it retains the solar heat, resulting in higher efficiency.

A heat sink (hot system) – applications

The heat is transferred to a hot system, which is often referred to as heat sink. The heat goes from the heat pump condenser, where the refrigerant changes its phase from gas to liquid, to the consumer. The application of the heat pump solution is very wide and extends to a great variety of sectors.

- Residences: the accommodation to live has associated a heat demand in most cases, both for air conditioning and hot water, which can be provided by a heat pump. This includes particular residences and hotels, with different load profiles in a wide size range.

- Business buildings: the spaces dedicated to business can be very diverse, as they include shops, offices, bars, restaurants, etc. The usual destination of the heat demand is air conditioning and hot water, but some businesses may have specific applications similar to small industry.

- Process industries: having a process with heat requirements is pretty common. They are often large consumers and their load profile is particular to each production process, even if they share common traits. Having an industrial heat pump can solve some of their emission issues.

The future of heating: District Heating

Depending on the application and use of the heating necessity, the hours where the peak demand takes place can vary significantly. Bringing together the different heat demand profiles with high requirements result in a more efficient design, as the heat production can be centralized and simultaneity coefficients can be applied. This is why District Heating makes sense. The preference for heat pumps in District Energy has to do with the fact that this technology is very energy efficient. The energy that the heat pump is consuming is electrical energy, and this consumption is way less than the heat they are producing. Most industries are striving to keep energy consumption as low as possible, which is understandable given the rising energy costs.

Moreover, the electrical energy consumption means that no gases are released to the atmosphere, which leads to their easy implementation in urban areas. Renewable electricity production is being implemented worldwide to fight against global warming, therefore the electric driven heat pump is already prepared for working together with these technologies.