Chilled water thermal energy storage (TES) has proven to be an effective technology for managing central cooling plants in some climates. Where it has been applied, this technology has often produced significant operating cost savings for owners, added flexibility to plant operations, and enhanced energy efficiency in the production of chilled water. At the center of this solution is the TES tank, which collects and stores chilled water from the system, mostly during the night. Diffusers are important components of the tank thermal stratification, so this article explains the importance proper diffuser design in regards to cooling efficiency.

Stratified Thermal Energy Storage

In stratified TES, natural stratification of chilled water takes place inside the TES tank. Since the water remains in liquid form, it qualifies as a sensible storage medium. The chilled water cooling system utilizes the TES tank as the main storage container in a process that involves CHARGING and DISCHARGING processes. TES charging mode involves an overnight process whereby the chiller stores cooling energy in the TES tank. The system withdraws warm water from the tank via the top diffuser and sends it to the chiller plant. Subsequently, cold water returns to the TES tank via the bottom diffuser following a cooling process in the chiller plant. Charging mode is complete when the tank is full of chilled water. The system is now ready for DISCHARGING. During the discharging mode, the chilled water which was previously stored is sent to the consumers. The chillers can be stopped or in operation, depending on the cooling demand. When this process is complete, the TES tank will be full of majorly warm water, and be set for the start of the CHARGING cycle. The presence of diffusers at both the top and bottom of the tank ensures the formation of a stable transition layer referred to as “thermocline”, such that the layers of chilled water below and the warm water above are perpetually separate. The cool thing about modern TES tanks is that their insulated walls ward off heat gain, thus enhancing efficiency. However, it is the design of the diffusers that does the magic for thermal stratification.

Different Types of Diffusers

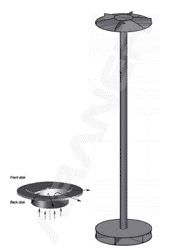

The type of diffuser used in thermal stratification matters a lot. There are several types of diffusers, but the radial version is recommended for cylindrical TES tanks. For this type, water is introduced into the tank along the perimeter of the diffuser plate and spreads radially. This diffuser is sturdy in design, meaning that it can withstand water surges and hammers.

Fig. 1: Radial Diffuser

The other version is an octagonal slotted-pipe diffuser, which consists of one or more concentric slotted octagonal pipe rings. Its operation is characterized by water being withdrawn and introduced through transverse slots cut in the diffuser piping walls on the side facing away from the tank interior. Compared to the radial diffuser, the octagonal diffuser requires more installation, but might be more cost-effective depending on the case and also can be adapted for different tank shapes.

Diffuser Design: Key to Reliable Cooling Efficiency

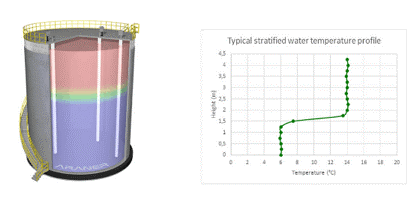

It is important to design and construct the diffusers to form and sustain stratification within the recommended flow rate level. Most important, the velocities at the inlet and outlet streams must be sufficiently low for the sake of a good balance between buoyancy and inertia. The basis of detailed diffuser design for thermal stratification is the fact that every TES customer comes with unique needs. To get the exact cooling requirements, the designed diffuser geometry must be subjected to real conditions. Alongside design, testing its performance before erection is also strongly advised. On design, the different types of diffusers are taken into account, with Computational Fluid Dynamics (CFD) simulation being a crucial approach. CFD is crucial because we must analyze the occurrence of the non-physical boundary called the Thermocline in natural stratification. Important parameters in the design include diffuser size, Reynolds number, Diffuser Type, chilled water temperature and warm water temperature. Others are Aspect Ratio and flow rate.

Fig 2: CFD Analysis Comes in Handy in Design

Temperature difference is crucial as it determines tank capacity. The need to maintain the boundary makes the mixing of the water an intricate process. Specifically, mixer design can be a daunting task in TES systems, so CFD comes in handy as a reliable tool for unique designs.

Conclusion

ARANER are specialists in diffuser design method for efficient district cooling. They solve complex flow problems using high-speed computers and numerical techniques. Using such an intricate solution is based on the knowledge that cooling efficiency is dependent on diffuser design for thermal stratification. You can contact the experts for more insights regarding this solution.