Whether we realize it or not, we are in the middle of an energy crisis. After decades of unprecedented development in all corners of the globe, the energy demand has become extremely high, being the economic development and the constant population growth in big cities its main drivers. When we consider the consequent rapid increase in energy consumption, the critical importance of planning a sustainable energy supply becomes clear. Solving this challenge will require greater effort in increasing the efficiency of important processes that will play a part in the future of energy, such as District Cooling systems.

District Cooling in Smart Cities

The development of smart district cooling systems aims to improve the management and use of energy demand. District cooling covers the generation and distribution of refrigeration streams in district networks. Some districts in the United Arab Emirates, more precisely in Dubai, have already implemented their first networks with smart district cooling systems, taking a meaningful step forward into the future of district cooling. For its remarkable energy efficiency, district cooling has become a sustainable solution for high-density buildings. However, it can eat a big portion of the power budget if this efficiency is overlooked.

The Ultimate Efficiency Measure: Thermal Energy Storage

One of the best ways to increase the efficiency of a district cooling plant is the effective implementation of a Thermal Energy Storage (TES) system. A TES system can be defined as a technology utilized to accumulate thermal energy during the periods of excess of production (off-peak time), to use it during the periods of shortage of production (on-peak time). And, what are the benefits of TES applied to District Cooling plants? First, the overall cost of the installation is lower. This is because the installed capacity of the refrigeration plant is reduced, leading also to a reduction in the plant dimension. Alongside that, there is a reduction in the operational cost, as peak consumption can be avoided during high electrical tariff periods. The environmental impact is also mitigated as the CO 2 emissions are reduced, thanks to the improved operating efficiency when storing the energy.

TES Technologies for DC Applications

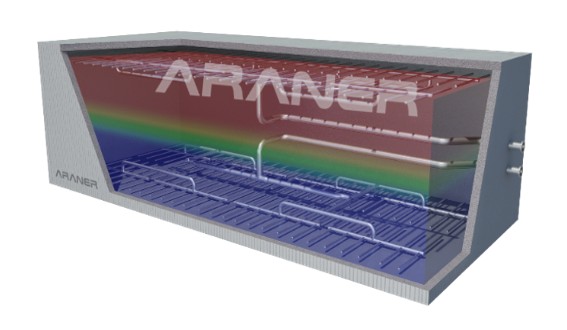

Fig.1: ARANER Thermal Energy Solutions

Thermal energy storage comes in various technologies that store energy in the form of chemical energy, latent heat, or sensible heat. A more specific categorization of TES technologies is as shown below. Whereas ice storage uses the latent heat of fusion of water to store cooling, chilled water storage uses the sensible heat capacity of water. As a simple thought, if you are looking at overall efficiency, the chilled water type scores very highly. However, they tend to occupy larger space than the ice storage technologies. Interestingly, the chilled water solutions are more affordable than the ice ones are. At ARANER, we are always happy to help our clients with this important decision in order to select the best thermal energy storage option for their cooling plants.

Issues to Consider in TES System Sizing & Design

Fig.2: TES Tank with Stratified Water

In District Cooling, TES allows for average load-based sizing of chillers as opposed to peak load sizing. This reduces the operating costs of chillers significantly considering that off-peak power rates are normally low. When sizing the system, we must look at several details to calculate the optimal system size: cooling loads profile, plant details and, operating patterns and temperatures. It is also important to consider the factors upon which we will base the design, such as:

- The tank capacity on size of cooling plant.

- The minimum operating time for the plant. This approach is mostly applicable where equipment cycling is undesirable.

- Meeting the cooling demand of the smallest zone within the district. This is essentially the most critical zone that needs cooling the most.

Keep in mind that a TES system for District Cooling doesn’t work without issues and it is important to remember them in the design stage. The Thermal Energy Storage system must be safe and energy efficient, but also controllable. Even more important is to avoid either over-sizing or under-sizing. An under-sized TES tank doesn’t store sufficient cooling from the plant, hence it is inefficient. Moreover, such a tank is incapable of supplementing the chiller plant output during times of peak cooling demand. Similarly, an over-sized tank would be inefficient as well.

How to Ensure the Design: Computational Fluid Dynamics

As shown in this video, Computational Fluid Dynamics (CFD) simulation is a specialized tool to explore the effects of all the variables involved in the fluid system in order to obtain the optimal design of the TES tank and maximize its performance. Without modifying or installing a real system or a prototype, CFD simulation can forecast which changes in design layout are most vital to improve the performance of the TES Tank. Being able to check the performance inside the tank, ARANER guarantees the cooling load required for the District Cooling Plants. Our engineering team has wide experience in using simulation software and works with the most recent CFD tool in the market. In ARANER we put a great effort to design, manufacture and install the most efficient TES solutions for every District Cooling Plant.

Conclusion

ARANER helps clients to make the right decision when selecting the best Thermal Energy Storage Technologies for District Cooling Plants. We certify the performance of all tailor-made solutions and always offer excellent service. If you want to take advantage of benefits like capital cost reduction, increased efficiency, and reduction in peak electrical consumption, consider using a TES technology for your District Cooling plant. Our experts are always eager to assist you to achieve the perfect solution for your application. To learn more in-depth information about Thermal Energy Storage, download our technical ebook for free. Get in touch with us!