Thermal Energy Storage (TES) systems capture and store heat or cooling for later use, enabling renewable energy integration, reducing peak demand, and improving efficiency. There are three main types — Sensible Heat Storage (SHS), Latent Heat Storage (LHS), and Thermochemical Storage (TCS) — each with unique principles, advantages, and applications. Beyond the technical differences, TES delivers major economic, environmental, and operational benefits, making it a key technology for industries worldwide, especially in regions with high cooling demand like the Middle East.

Why Thermal Energy Storage matters now

As the energy transition accelerates, intermittent renewable sources such as solar and wind are becoming central to power generation. This shift brings challenges: supply and demand peaks rarely match, and conventional backup systems often rely on fossil fuels.

TES addresses this gap by producing thermal energy — heating or cooling — during off-peak hours, when energy is cheaper and often cleaner, and storing it for use during peak demand periods. This process:

-

Reduces the size (and capital cost) of required heating and cooling plants.

-

Cuts waste by storing energy that would otherwise be lost.

-

Lowers greenhouse gas emissions and air pollution.

-

Improves overall grid stability and energy security.

The International Energy Agency (IEA) highlights TES as one of the most impactful tools for energy efficiency and renewable integration in the coming decade.

What is a Thermal Energy Storage System?

A Thermal Energy Storage (TES) system captures thermal energy in a medium and releases it later when needed. This can involve:

-

Changing the temperature of a medium (sensible heat).

-

Harnessing a phase change (latent heat).

-

Storing energy in chemical bonds (thermochemical storage).

TES can be integrated into:

-

District cooling and heating systems.

-

Industrial processes requiring high or stable temperatures.

-

Renewable energy plants to balance generation and demand.

-

Combined systems with technologies like Turbine Inlet Air Cooling (TIAC).

The three types of Thermal Energy Storage Systems

1. Sensible Heat Storage (SHS)

Sensible Heat Storage is the most established and widely used TES technology. It works by raising or lowering the temperature of a storage medium — such as water, rock, concrete, or molten salts — without changing its physical state. The more thermal energy you add, the higher the temperature of the medium; conversely, energy release lowers its temperature.

Because it is based on simple, well-understood principles, SHS is often chosen for projects requiring reliability and cost-effectiveness. The energy storage capacity depends directly on the specific heat capacity of the medium and the temperature difference between charging and discharging phases.

Examples:

-

Hot water storage tanks in residential, commercial, and district heating systems.

-

Concrete thermal mass integrated into building structures to stabilize indoor temperatures and reduce HVAC loads.

-

Molten salt tanks in Concentrated Solar Power (CSP) plants, allowing energy collected during the day to be used at night.

Advantages:

-

Low installation and maintenance cost.

-

Straightforward design and operation.

-

Long operational lifespan with minimal performance degradation.

2. Latent Heat Storage (LHS)

Latent Heat Storage takes TES a step further by using the energy absorbed or released during a material’s phase change — typically from solid to liquid, liquid to gas, or vice versa. This process allows large amounts of thermal energy to be stored at a nearly constant temperature, making LHS ideal for applications where temperature stability is crucial.

The key to LHS systems is Phase Change Materials (PCMs), which can store 5 to 14 times more heat per unit volume than sensible storage media for the same temperature range. This higher energy density enables more compact systems, which is a major advantage in space-constrained installations.

Examples:

-

Ice storage systems: Water is frozen during off-peak hours when electricity is cheaper, then melted during peak hours to provide cooling for commercial buildings, hospitals, or stadiums.

-

PCM panels and building materials: Integrated into walls or ceilings to passively regulate indoor temperatures, improving comfort and reducing HVAC loads.

-

Solar thermal collectors with PCMs: Capture daytime heat and release it at night for heating or hot water production.

Advantages:

-

Higher energy density than SHS, reducing footprint.

-

Maintains steady output temperature during the phase change.

-

Ideal for cooling applications and precise temperature control.

-

Potential for integration with renewable energy systems for demand shifting.

3. Thermochemical Storage (TCS)

Thermochemical Storage represents the most advanced and highest-density TES technology. Instead of storing heat in a material’s temperature or phase change, TCS uses reversible chemical reactions to capture and release thermal energy.

When the reactants combine, they either absorb or release heat. This energy can then be recovered later by reversing the reaction. Because the energy is stored in chemical bonds rather than as heat in a material, there is no self-discharge over time, making TCS ideal for seasonal or long-term storage.

Examples:

-

Metal hydrides: Store hydrogen and release it with heat for combined heat-and-power systems.

-

Metal oxides: Store solar heat for high-temperature industrial processes like cement or steel production.

-

Salt-based thermochemical systems: Provide seasonal heating for residential or district energy networks.

Advantages:

-

Highest energy density of all TES types — several times greater than LHS.

-

No thermal losses during storage, enabling energy to be kept for months without degradation.

-

Suitable for high-temperature applications where other storage media may be impractical.

-

Flexible integration into industrial, commercial, and renewable energy systems.

Where TES makes the biggest difference

1. Meeting Peak Cooling demand

In many climates, peak cooling needs coincide with peak electricity demand, putting pressure on both power plants and the grid. TES allows cooling systems to run at night (off-peak hours) and store chilled water or ice for use the next day, reducing daytime power demand and operational costs.

2. Facilities with excess Off-Peak capacity

If a system has excess capacity at night but struggles during peak hours, TES stores that unused cooling or heating and deploys it exactly when needed, avoiding expensive equipment upgrades.

3. Combined with other technologies

TES can enhance the efficiency of other systems:

-

Turbine Inlet Air Cooling (TIAC): Stored chilled water improves turbine output during hot weather.

-

District Cooling: TES provides backup during maintenance or equipment failure.

-

Renewable Integration: Stores surplus renewable energy as heat or cold for later use.

4. Regional advantages – The Middle East case

In regions such as UAE, Saudi Arabia, and Qatar, rapid growth and high cooling demand make TES essential. In some countries, it’s even mandated by law for certain projects to help meet national energy efficiency and climate targets under the Paris Agreement.

TES helps these regions:

-

Reduce strain on the grid.

-

Cut reliance on fossil fuel backup systems.

-

Lower carbon footprints.

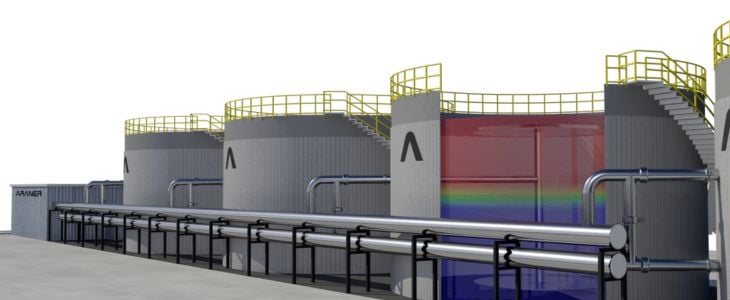

Real-World TES applications by ARANER

Farah Hospital – Amman, Jordan

One of the Middle East’s largest hospitals needed a LEED-certified expansion. Instead of traditional diesel boilers and electric chillers, ARANER installed a 1,280 TR·h TES tank with 3,300 kW high-efficiency industrial heat pumps. The result: lower operational costs, reduced plant capacity requirements, and increased energy efficiency. Discover more about this project.

Qatar Football Stadium

For one of the world’s most famous stadiums, ARANER implemented a 30,000 TR·h naturally stratified TES tank to meet peak cooling demands, manage load variations, and serve as a backup for chillers — ensuring comfort during high-profile global events. More about Qatar Football Stadium.

How to choose the Right TES System for your project

When deciding between SHS, LHS, and TCS, consider:

-

Temperature requirements

-

Storage duration (short-term vs. seasonal)

-

Available space

-

Budget and CAPEX/OPEX goals

-

Integration with existing systems

A hybrid approach — combining heat pumps with TES — often delivers the best efficiency and ROI.

TES at the heart of the energy transition

Thermal Energy Storage systems are a cornerstone of modern energy infrastructure, enabling efficient, sustainable, and reliable heating and cooling. Whether it’s storing solar heat for night-time use or cutting peak demand costs, the right TES system can transform project performance.

ARANER specializes in custom-designed TES solutions that optimize cost, capacity, and sustainability. Contact our engineering team to explore how SHS, LHS, or TCS could benefit your project and help you meet your efficiency and sustainability goals.

FAQs about Thermal Energy Storage Systems

1. What is the main purpose of a Thermal Energy Storage (TES) system?

A TES system stores heat or cooling for later use, helping balance energy supply and demand, reduce peak loads, and improve integration with intermittent renewable sources like solar and wind power.

2. Which TES type has the highest energy density?

Thermochemical Storage (TCS) offers the highest energy density, long-term storage capability, and no self-discharge, making it ideal for seasonal and high-temperature applications.

3. How do TES systems help with renewable energy integration?

TES captures excess renewable energy during high production periods and stores it for use when production drops, reducing reliance on fossil-fuel backup systems and stabilizing the grid.

4. What industries benefit most from TES systems?

TES is widely used in district cooling and heating, industrial processes, hospitals, stadiums, data centers, and renewable energy plants.

5. Can TES reduce energy costs?

Yes. By shifting energy use to off-peak times and reducing the size of required heating and cooling plants, TES can significantly cut both operational and capital costs.

6. How do I choose the right TES system for my project?

Consider your required temperature range, storage duration, available space, budget, and integration with existing infrastructure. Consulting with a TES engineering specialist ensures optimal system selection.