New challenges are raising worldwide in the majors cities to reduce the CO2 emissions at the same time that heating and cooling systems demand is growing due to the climate change. In all these cities, there is the same common denominator: the excess heat produced in the wastewater treatment plants. But is it possible to turn wastewater into a source for heat pumps?

Wastewater from medium and large municipalities always contain a certain amount of heat.

Actually all majors public or private water treatment companies are focused on the biogas generation from the sludge’s treatment and it makes sense that the methane production is a high interesting business and added value to create a circular economy reducing our natural gas dependency.

However, the other side of the water treatment plant, effluent water, can be considerably higher temperature heat source than other costly one with a more reliable and stable way to reuse in a district energy plant.

This waste heat could be a common solution for a potential large range of cities worldwide to obtain a radically CO2 emissions reduction with high efficiency coupling heat pumps.

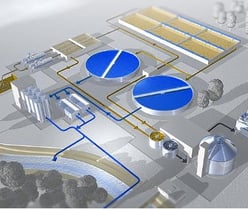

Wastewater treatment plant for district energy providers

The water treatment plant process could be achieve by different processes as flocculation, sedimentation, filtration, disinfection, sludge drying, fluoridation and a final pH correction. Some of these processes are exothermic, so there is an increase in the temperature of the treated water throughout the different steps.

Almost all municipalities try to maintain and respect a maximum return temperature to the public water supply chain based on a minimum time of residence.

Heat recovery from wastewater could be a considerable source of energy for heat pumps and at water utilities.

Low grade recovered heat could be used for the water utility buildings space heating or for other heating processes for external usage as a district energy.

The use of heat pump coupled to the internal and renewable electricity production from biogas boiler could be a benefit to be promoted to increase the projects reliability.

On top of the heat recovery potential for district heating proposal it could be also an opportunity to reduce biogas self-consumption in the water treatment plant and increase their benefit providing higher amount of biogas to the gas grid network.

The use of heat pump technology could also increase the overall efficiency of the heat recovery system by being able to provide district cooling energy during the summer season.

Depending on different factors water treatment plant heat recovery systems could be implemented in almost all sizes and types of cities creating a large amount of waste heat at interesting temperatures to be reused as heat source in heat pump.

The temperature, however, depends on a number of factors, mostly on the outside and ground temperatures, the length of the sewage pipe and the retention time of wastewater in the sewer.

A heat recovery system in a wastewater treatment plant

Heat recovery systems as simple heat exchangers are installed in all majors’ large water treatment plants to be used as low-grade heat source as a counter flow for the proper treatment processes.

For other processes as heating digester or sludge’s drying higher temperatures are needed so that gas boiler are used with hot water temperature.

Another way to recover heat in wastewater treatment plant is to extract heat from the effluent water to be used as a heat source in a heat pump machine.

Normally temperature at this stage would vary between 20-25ºC in summer time down to 12-10 ºC in wintertime depending the outside air conditions. The heat pump system consist in an evaporator where effluent water is cool down around 4 to 12ºC depending the period of the year and its inlet temperature. The more the temperature can be allowed to decrease, to avoid freezing it, the more heating energy can be extracted.

Normally temperature at this stage would vary between 20-25ºC in summer time down to 12-10 ºC in wintertime depending the outside air conditions. The heat pump system consist in an evaporator where effluent water is cool down around 4 to 12ºC depending the period of the year and its inlet temperature. The more the temperature can be allowed to decrease, to avoid freezing it, the more heating energy can be extracted.

The refrigeration loop will use a Carnot principle to elevate the pressure of the refrigerant employed up and compressed it in the compressor. Then passing this hot refrigerant gas by the condenser the loop will be closed coming back to the evaporator after its expansion. The proper heat pump controller could control the heating process of the hot water it has produced on the condenser and depending on the level of temperature required it.

Some of the heating processes (digester or sludge drying) inside the plant could require hot water temperature between 60ºC to 80ºC, building space heating between 50ºC to 80ºC and a district heating network between 60ºC up to 85ºC.

The heat pump efficiency will vary in function of the final usage of the hot water but it could be relatively simple to integrate this technology in almost all range of plant sizes and countries.

The main reasons to promote this heat recovery application are:

⮚ Reduce the CO2 emissions for internal heating processes

⮚ Reduce biogas or gas consumption for self-consumption

⮚ Increase biogas selling to the gas network

⮚ Recover energy and integrate renewable energy sources

⮚ Create an added value business collaborating with district energy providers

⮚ Simple solution to promote decarbonization in all sizes of cities

Why heat pump integration is an opportunity for utilities providers?

Decarbonization of the industry and the large cities is one of the major challenge never done and this revolution will need all the efforts from an engineering point of view to assess which heat sources are the most common and simple to be reused in thermal energy sector.

This efficient way to produce thermal energy could be the key success factor to start an easier energy transition in most of the medium and large cities worldwide.

All major energy utility providers companies would need to focus their first effort to create collaboration agreement with wastewater treatment utilities providers to ensure that a great part of their base load production be produced from low cost heat source and high efficiency heat pump systems.

Different reports realized by different environment engineering companies and public departments find in their waste heat mapping the sewage water treatment plant as one of the biggest potential to reduce their CO2 emissions and satisfy their reductions objectives.

At the same time treatment, plant operators have a clear objective to increase their biogas production to serve it to the gas network increasing their benefits as new stakeholders in the market.

Definitively the heat recovery systems based on heat pump could provide different benefits for water utility provider business as:

- Reduce biogas self-consumption

- Increase their economic benefits with thermal energy

- Provide clean and reliable electricity to the heat pump system

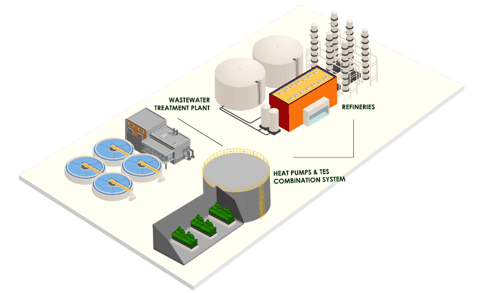

This business diversification will help to all stakeholders to promote this heat recovery retrofit in all existing plants and to develop these systems as a standard in all new projects as one employed in Canada by METRO VANCOUVER public development for the new wastewater treatment plant that be held for North Vancouver area.

Wastewater treatment plant heat pump integration

ARANER is participating in different heat pump projects but sewage water heat recovery system are one of the most energy efficient to be applied in a simple way.

This heat pump integration could be improved if renewables energies are coupled and a thermal energy storage will be implemented to increase the heat recovery capacity during whole year.

Check our website for more information on this topic and the district heating market.