Every operator has the big role of promoting optimum efficiency of gas turbines and facing water condensation in TIAC. Given the economic upheavals of recent times, any technology or solution that generates profits through increased profitability worth a try. When gas turbines run efficiently, they also help to safeguard the environment because emissions are minimal. Over the years, several technologies for enhancing the gas turbine (GT) output have emerged. Since temperature and humidity of the air entering the GT affect the operation and efficiency of the unit, most of these technologies focus on controlling these elements.

What are TIAC Systems?

TIAC stands for Turbine Inlet Air Cooling. As the air is cooler, it is also denser, which means more mass of air in the same volume. This improves the compression relation of the gas turbine and consequently its performance. The rated performance of gas turbines is based on these conditions: 60% Relative Humidity (RH), air pressure at sea level, and 15°C temperature. Outside of these parameters, then the GT will most likely have a lower performance. During hot days when power generation demand rises, the operator may actually suffer a reduction of the performance of the GT. With gas Turbine Inlet Air Cooling, this problem can be controlled. There are two main methods: Evaporative cooler and Inlet chiller. Evaporative cooling has been around since time immemorial and is still a cost-effective method of cooling GT inlet air. However, absorption chillers, mechanical chillers, and TES systems are some of the modern solutions being applied widely.

Presence of Water Condensation in TIAC

Gas turbines are designed to work in a broad range of conditions. They could even operate with 100% relative humidity. Nevertheless, free moisture is not advisable for the gas turbine. The presence of water or condensation in a gas turbine can be extremely harmful. If the water enters the blade area, it can cause erosion and corrosion of the surfaces. The steam turbine obviously needs a robust water removal mechanism, but the gas turbine requires it as well. Ambient conditions and factors related to the TIAC process itself could introduce condensate water into the process. A properly designed and installed filtration system is necessary to keep the GT in good shape. That is why ARANER installs a protective layer for the gas turbine and its components.

Methods of Countering Water Condensation Effectively: ARANER Technology

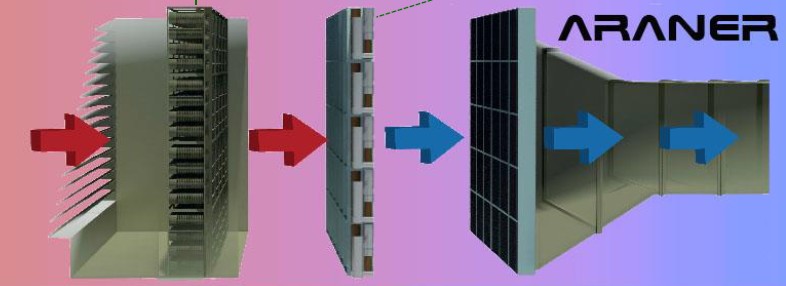

The best inlet air system needs to protect the turbine in all respects to not only maintain superior performance but also prevent costly repairs/replacements. Condensation introduces water droplets into the gas path, so this problem must be handled effectively. ARANER’s TIAC solution consists of air heat exchangers, whose role is to offer indirect cooling to the air before it enters the turbine compressor. These heat exchangers are positioned after the filter section. Since the heat exchangers have droplet catchers, any condensate from the cooling coils is trapped.

Fig 1: ARANER Heat Exchanger

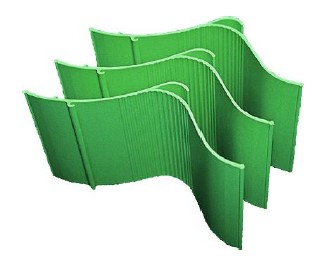

After many years of experience, ARANER has developed two main solutions to help to remove condensate from the inlet air stream of TIAC technologies in an effective way: the ARADrop and the ARATrap. ARADrop is a droplet catcher system that removes the humidity condensation water drops with an efficiency of 99.9 %. By removing every drop from the water, the turbine integrity is assured. The specially designed configuration also makes sure that the pressure drop is minimum so that airflow is not disturbed.

Fig 2: ARADROP

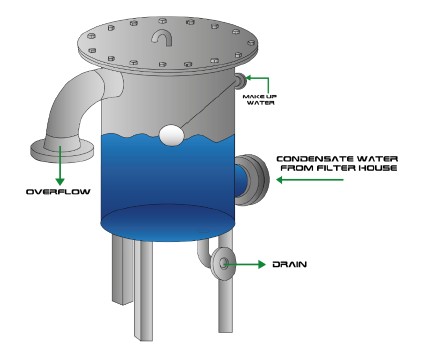

The ARADrop slats trap the water drops in the air and collect them down in the condensate water tray. From there it is conducted to the ARATrap. ARATrap is a water seal device designed by ARANER to prevent the ingestion of unfiltered air through the condensate drain piping due to the air pressure difference between the ambient and the filter house interior. ARATrap collects the condensate water and sends it to the drain line, and at the same time, it ensures that the unfiltered air does not enter the filter house through the condensate drain system.

Fig 3: ARATRAP

When the TIAC system is off or it is running but the ambient conditions are not prone to produce condensate water, the ARATrap should not receive any condensate water. If it does, it is possible to have a leak within the filter house, in the coils, and the ARATrap gives an alert. This makes the combination of the TIAC control system and ARATrap indispensable.

Conclusion

Whether your gas turbine is exposed to an extremely cold or humid environment, you can still enjoy the power augmentation benefits of TIAC technologies. ARANER has been applying ingenious methods of dealing with the condensation challenge for the sake of system integrity. Get in touch with a company representative to discover how you can take advantage of the best solutions against water condensation in TIAC technologies.