Choosing the correct tank diffuser is one of the most decisive engineering steps in achieving high performance in a Water Thermal Energy Storage (TES) system. TES tanks rely on stable thermal stratification - warm water at the top, cold water at the bottom - to store and deliver cooling efficiently. Because stratification depends heavily on how water enters and exits the tank, diffuser selection directly influences thermal efficiency, capacity recovery, mixing losses and overall reliability.

Industry associations such as the International District Energy Association (IDEA) and Euroheat & Power highlight diffuser performance as a core component in district cooling systems that use stratified TES tanks. Proper diffuser engineering ensures that thermal layers remain intact throughout charging and discharging cycles, maximizing the economic and energy benefits of TES.

This guide explains how TES works, what tank diffusers do, the different diffuser types, performance metrics and how to select the ideal diffuser for your TES tank.

How does a TES Tank work and why do diffusers matter?

A chilled-water TES tank functions by maintaining natural stratification:

-

Warm water rises to the top of the tank

-

Cold, dense water settles at the bottom

-

A thin transition zone, the thermocline, forms between both layers

This separation allows TES systems to store cooling energy during off-peak hours and release it during peak demand.

Why stratification depends on diffusers

If water enters the tank too quickly or with turbulence, it disrupts the thermocline, causing mixing that reduces usable cooling capacity. Organizations such as ASHRAE—which publishes widely used TES and chilled-water design guidelines—emphasize that diffuser design is the key factor in maintaining laminar, low-velocity flow.

Diffusers therefore determine whether a TES tank performs at its intended efficiency or suffers from significant mixing losses.

What is a Tank Diffuser?

A tank diffuser is a specialized inlet/outlet device installed at the top or bottom of a TES tank to regulate flow distribution during charging and discharging.

Its main functions are to:

-

Slow down incoming water

-

Create laminar flow instead of turbulence

-

Spread water evenly along tank surfaces

-

Prevent thermal mixing

-

Preserve the thermocline

-

Improve overall tank efficiency

In TES applications—especially those documented by the Cooling Technology Institute (CTI)—diffusers are considered essential structural components, not optional accessories.

What Problems Do Diffusers Prevent?

Without a properly engineered diffuser, the tank may experience:

-

Turbulence

-

Variable dispersion

-

Foaming

-

Aeration

-

Excessive inlet velocity

-

Water hammer

-

Surge shocks

-

Cavitation

-

Severe layer mixing

-

Loss of thermal storage capacity

A well-designed diffuser mitigates all these issues by ensuring controlled, predictable flow behavior.

Types of Tank Diffusers for TES Systems

TES tanks typically use two categories of diffusers: radial diffusers and slotted diffusers. Each is suited to specific hydraulic and operational conditions.

Radial Diffusers

Radial diffusers are composed of one or two horizontal plates arranged parallel to the tank floor or ceiling. They provide a wide area—five times larger than the inlet pipe—for water to expand and slow down before being redirected.

Advantages

-

High resistance to surge and water hammer

-

Simple, durable structure

-

Good for systems with fluctuating flow

Limitations

-

More complex installation

-

Lower precision in fine stratification

-

Higher cost in large diameters

Radial diffusers are widely referenced in design guides for district cooling systems supported by IDEA and CTI, which highlight their robustness under unstable hydraulic conditions.

Slotted Diffusers

Slotted diffusers use ring-shaped pipes with machined openings facing the tank wall. This design ensures uniform vertical dispersion of water.

Advantages

-

Superior stratification performance

-

Very sharp thermocline

-

High efficiency and uniform distribution

Limitations

-

More sensitive to flow surges

-

Higher pressure drop

-

Requires precise sizing and engineering

Slotted diffusers are frequently referenced in Euroheat & Power case studies where TES is used in high-efficiency district cooling networks.

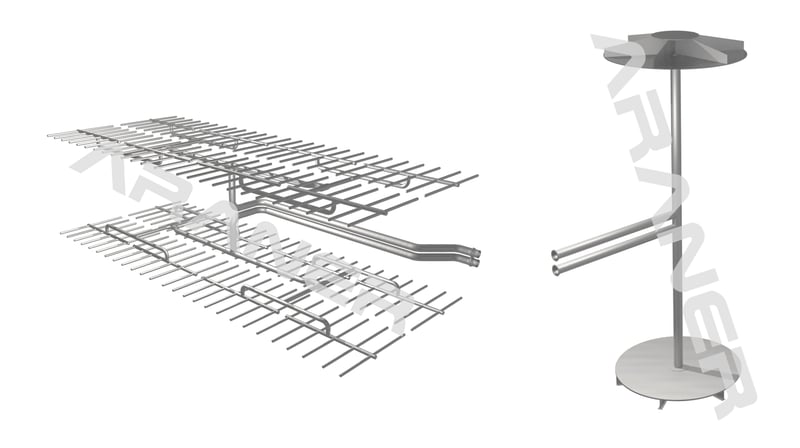

Figure 1: Slotted Pipe Diffuser and Radial Diffuser for TES Tanks

How to choose the correct Tank Diffuser for your TES Tank

Selecting the right diffuser requires engineering analysis based on system conditions, thermal goals and tank geometry.

1. Evaluate Flow Conditions

Ask whether the system will experience:

-

Flow surges

-

Water hammer

-

Rapid flow fluctuations

If yes → Radial diffusers are preferred.

If the system has stable flow → Slotted diffusers may offer higher efficiency.

2. Define Performance Objectives

If your priority is:

-

Maximum stratification

-

Highest thermal efficiency

-

Best Figure of Merit (FOM)

→ Choose slotted diffusers.

If your priority is:

-

Robustness

-

Tolerance to surges

-

Long-term stability

→ Choose radial diffusers.

3. Consider Tank Geometry

-

Tall and narrow tanks → slotted diffusers work exceptionally well.

-

Wider tanks → radial diffusers may distribute flow more evenly.

4. Assess Temperature Difference (ΔT)

Low ΔT = low density difference, harder to stratify →

Slotted diffusers perform better.

High ΔT = easier stratification →

Both diffusers can work, selection depends on flow conditions.

5. Review Cost, Maintenance and Installation Needs

Radial diffusers → simpler, stronger, lower maintenance

Slotted diffusers → more efficient but more complex

6. Use CFD and TES Modeling

Advanced TES projects—especially in district cooling—benefit from:

-

CFD simulations

-

Thermocline modeling

-

Full system flow analysis

ARANER performs these simulations to ensure that the diffuser is perfectly matched to project requirements and international guidelines such as those recommended by ASHRAE and IDEA.

How to Measure TES Diffuser Performance

Performance is assessed using the industry’s standard metrics:

Thermal Efficiency (η)

How much chilled-water capacity is recovered vs. stored.

Figure of Merit (FOM)

Measures usable energy delivered during discharge.

Lost Capacity (Cₗₒₛₜ)

Energy lost due to mixing or poor layer separation.

The right diffuser significantly improves all three indicators.

Conclusion

Choosing the correct diffuser for your TES tank is essential for:

-

Strong stratification

-

Maximizing usable cooling capacity

-

Reducing mixing losses

-

Improving operational efficiency

-

Reducing pump stress

-

Ensuring predictable performance

Both radial and slotted diffusers are valid options—what matters is selecting the one that aligns with flow behavior, tank geometry, thermal requirements and system design.

ARANER uses advanced engineering analysis and simulations to select or design the optimal diffuser for each TES installation.