Thermal energy storage (TES) using chilled water is a popular solution for facilities across the globe because of low operating and maintenance costs as well as minimal complexity. As long as there is enough space to accommodate the sizeable tanks, any building can use this method. The operation of the TES system is inherently efficient. The chilled water plant produces and stores chilled water during off-peak power demand at night. It releases the chilled water during daytime for cooling applications. The right balance between the different systems, defined by the operating strategies and modes, contributes to the optimal performance of the cooling plant. With a correctly designed and sized system, the most demanding cooling needs of a facility can be met. Around the globe, ARANER has successfully installed chilled water systems for turbine and district cooling.

Operating strategies

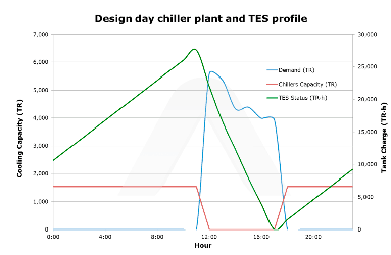

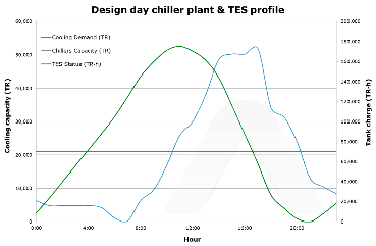

The evaluation of the weather data and the required daily cooling load enables TES tank designers to determine the optimal design and operating conditions. The cooling capacity and dimensions of the TES tank, among other factors, are defined in order to satisfy the highest cooling demand. As shown in Figure 2, cooling energy can be required during a limited number of hours per day by only using thermal energy storage ( full storage) or during most of the hours of the day by using the chiller units in conjunction with the thermal storage system ( partial storage).

Figure 1

Figure 2

TES Tanks: Operating modes

The above examples of operating strategies implement different modes of operation to optimally meet the cooling needs. In the case of full storage, the chiller charges the tank during the off-peak period ( charging storage with no load). In the discharging phase, when the energy is needed, the chiller is stopped and the TES tank will be the responsible to supply the required chilled water ( meeting load from discharge only). With this method, the system will improve the energy efficiency on the required hours since the electrical consumption is minimized by having the chiller stopped. The other typical case is when cooling energy is demanded during most of the hours of the day, for example in District Cooling applications. For this case, the chillers need to operate at a constant rate and the TES tank is installed in order to complement the energy supplied by the chiller. With this configuration, the chiller is running at every hour. When the cooling demand is lower than the chillers cooling load, the excess of capacity generated by the chiller is accumulated in the tank ( charging storage while meeting the load). On the other hand, if the cooling demand is higher than the chillers cooling load, the already accumulated capacity in the tank in the previous hours is used to supplement the chillers cooling load ( meeting load from discharging and direct equipment). By this way, the refrigeration plant size is reduced because the capacity needed for the chillers will be lower, and the chillers are working under constant conditions for the whole day, using the tank as buffer tank to cover the variations in cooling demand.

Supplementary considerations

Although TES technology is characterized by a low maintenance cost, certain supplementary considerations contribute to the enhanced long-term operation of the storage plant. The integrity of the TES system throughout its lifetime depends on the system cleaning from the beginning which must adhere to the local authority regulations. When chemicals are used, the compatibility of these products with system materials must also be checked with chemical suppliers for any limitations in the use of such additives. The monitoring of the water temperature and level contributes to maintain the volume of storage media and the cooling capacity of the system in accordance with the design conditions. Manufacturer’s instructions provide the guidelines to properly operate the system and the treatment of the storage media. Regular inspections of materials and sensors contribute to keep the performance level as at the commissioning of the plant.

To conclude

TES systems represent a cost- and energy-efficient solution to meet the most demanding cooling needs. The right balance between the operation of the different systems in accordance with the required daily cooling load is a key factor in the optimal performance of cooling plants. If you want to improve your TES facility or are planning to install one and need the advice from experts, do not hesitate to contact ARANER’s team. We are glad to help! If you enjoyed this post about TES tanks, you may be want to know how to improve a chilled water refrigeration system.