Water Thermal Energy Storage (TES) is used to increase capacity and lower operating costs of direct energy systems. The technology relies on the natural stratification of water in a tank, withdrawing warm water from the top of the tank where it rises and cold returns to the bottom where it settles.

Water enters the tank by means of diffusers, which reduces the velocity of the fluid entering the tank and encourages stratification by promoting laminar flow. Laminar flow occurs in sheets or layers of fluid next to each other and the vertical walls of the tank, without intermingling. Laminar flow happens parallel to the walls of the container, a Thermal Energy Storage tank in this case, and contains no type of current or swirls. A tall, narrow tank can reduce heat loss and mixing of layers because of reduced contact between the various temperature layers. More significant temperature differences between stored water and inlet water mean more substantial density differences; these differences reduce mixing naturally. Thermoclines, or transition layers, develop at higher inlet velocities when all these conditions exist; a higher aspect ratio and significant temperature and density differences.

What are tank diffusers?

There are multiple factors to consider when guaranteeing TES tanks work correctly, especially when considering the especially delicate operations involved in circulating substances at extreme temperatures.

This is particularly true regarding the entry and evacuation of both chilled and warm water or, in other words, the input and output of water or its charging and discharging. Throughout both these operations, a number of undesirable issues can take place if the right measures are not taken. These issues include:

- Turbulences

- Variable dispersion

- Excessive velocity

- Aeration

- Foaming

- High-flow surge conditions

- Cavitation

Tank diffusers represent a solution to minimize such matters. Located at the top or bottom of TES tanks, they are in charge of guaranteeing tank water can stratify so that the colder, denser water remains at the bottom and the warmer water stays at the top. Between these two layers of water, a transitional layer of water named thermocline is formed. When this layer is clearly defined and sufficiently thin, this combination of water layers will eliminate the issues named above, such as turbulence.

In order to do so, a number of operations take place within the diffuser, operations that are directly affected by the adequate design choices within the component. Typically, this will include curved interior flow channels for water to circulate, as well as annular outlets in charge of dispersing water.

Generally speaking, tank diffusers are used in the wider field of liquid flow systems with the aim of preventing foaming and other undesirable processes. Their invention relied on a series of developments, with some key names related to the U.S. patents leading to tank diffusers, including Albert C. Smith, Jr., George H. Gundlach and, Russell A. Gulick, among others.

Implementing the right type of tank diffusers is not only important to guarantee TES tanks work smoothly by implementing the right type of tank diffusers; it’s also key to extend pump life, as this is directly related to the occurrence of turbulence.

This importance is extended when considering how tank diffusers represent just one element in the bigger picture of a TES tank, as they are connected to the return flow passages and also directly in charge of conducting the returning liquid into the wider body of liquid in the tank in the right manner.

All in all, the right choice will be a system that presents a low maintenance and maximum efficiency when paired with its allotted TES tank. This might include the possibility of developing custom systems that respond to the specific needs of each system. Let’s now go through the different options when it comes to tank diffusers for TES tanks.

Types of Tank Diffusers used with TES

The diffuser selected for the inflow and outflow of the tank can help to improve the stratification of the tank and increase system efficiency. These devices need to be constructed to develop and sustain the various layers at the highest expected flow rate throughout the storage period. The diffusers used with chilled water TES tanks include radial diffusers and slotted diffusers. These diffusers have to keep the velocity low enough that buoyancy prevails over inertia, creating a current across the top or bottom of the tank, so the warm water “floats” on top of the cold water. Below we will discuss the characteristics of two different types of Thermal Energy Storage diffusers.

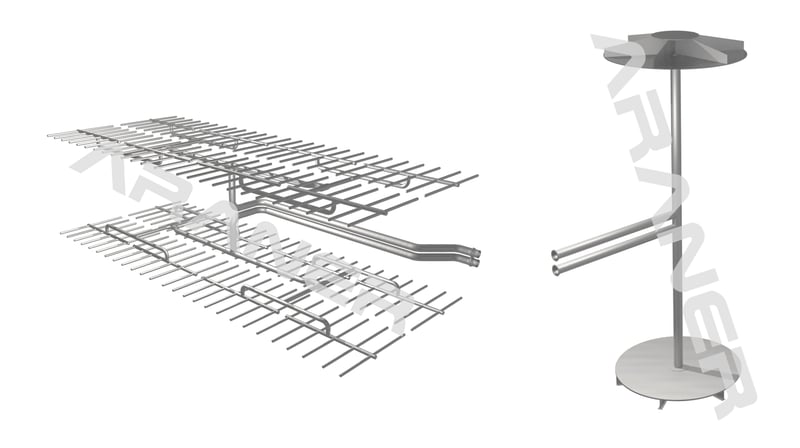

Figure 1: Slotted Pipe Diffuser and Radial Diffuser for TES Tanks

Radial Diffusers

A radial disk diffuser general comprises two circular plates mounted parallel to each other, or a single disk parallel to the top or bottom tank surface. The disks form a path for the water entering, or exiting, the tank. At the top of the tank, the surface of the water may form a spreading surface, whereas, with the tank bottom, the floor of the tank may form a dispersing surface below the diffuser, which forms the channel. The radial diffuser has an area about 5 times greater than that of the influent pipe, allowing the water to slow significantly before flowing into the tank and redirecting it to a more substantial portion of the tank. Radial disk diffusers are relatively simple in both structure and installation, yet highly effective. They stand up well to water hammer and surging and are best suited to tanks where this may be a problem. However, these diffusers may be difficult to install and can be expensive; therefore, it is essential to ensure that this is the correct diffuser for your application. ARANER will do a complete system and tank study in order to make sure you get the correct solution.

Slotted Diffusers

As its name implies, this type of diffuser consists of slotted pipes formed into ring shapes mounted horizontally in the center of the tank. The slots in the pipe of the diffuser face the side of the tank where the diffuser is mounted, top or bottom. The flow enters the tank through these slots, where it becomes dispersed along the vertical surface of the tank. Slotted diffusers require more precise design than radial diffusers but usually get better performance results. These diffusers are more vulnerable to the shock of water surges and experience a higher pressure drop than radial diffusers.

Measuring Stratified Thermal Tank Diffuser Performance

Several measures commonly used for quantifying the performance of stratified Thermal Energy Storage tanks include:

- Thermal Efficiency: The ratio of capacity delivered during a complete discharge cycle to that absorbed during a complete charge cycle of the tank. Thermal efficiency is a dimensionless number often represented by the Greek η.

- Figure of Merit (FOM): Described in terms of integrated capacity, which is the net amount of energy delivered or stored during the charging or discharging cycle or half-cycle in such cases.

- Cycle

- Half-cycle

- Lost Capacity (Clost): The capacity lost to mixing, outlet limitations, or is otherwise lost because it is unavailable at a productive temperature. This quantity can be measured during a cycle or half-cycle.

We see improvement in these measures with the installation of diffusers. Diffusers selected and sized appropriately for the tank, project, purpose, and other factors affecting performance are likely to provide the most considerable improvement in these and other quantifying factors used to gauge tank performance. Specially-designed diffusers may boost these metrics even higher by providing velocities and directional flow that enhances the natural stratification in the tank and increases overall efficiency.

Conclusion

Radial and slotted pipe diffusers each have their own advantages and considerations. The professionals at ARANER have experience using different TES diffusers in various applications. Let us perform a study of your system or project, new or existing, and tell you where diffusers could improve thermal stratification and efficiency in your Thermal Energy Storage tank.