District heating is set to play a key role in the pursuit of decarbonised cities and more efficient heating systems.

While cities account for more than 70% of global energy use and for 40 to 50% of greenhouse gas emissions worldwide (according to research by Seto et al), it’s increasingly clear that optimizing urban heating solutions is a crucial step to fight climate change.

In such a context, opting for the right district heating system is proving to be the source of major energy savings. At the same time, cost optimizations and other advantages brought along with district heating make these systems a convenient choice for end-consumers as well.

But what exactly is district heating, how do these systems work and what are the benefits of district heating? Keep reading to find out.

It may interest you: Heat pumps heating: an energy-efficient alternative

What is district heating

District heating refers to an urban-scale heating energy model where heat and cold are centrally produced and then distributed through pipe systems, which are responsible for making this energy available to end consumers.

In other words, in a district heating system, energy is produced at a high-performance central station and then transported through thermal fluids. This way, it’s possible to generate hot water and heating systems for both private and commercial buildings.

Elements in district heating systems

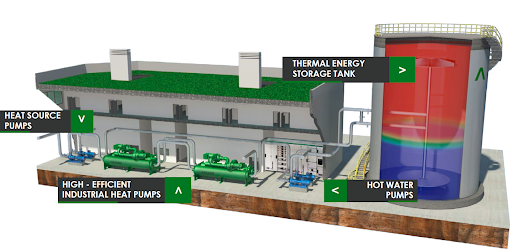

- Centralized production plant. The district heating plant is in charge of producing energy via multiple systems which are enumerated below in this article. For instance, in heat pump systems, these would be located at the centralized district heating plant. More complex district heating systems can incorporate more than one plant.

- Distribution Pipe Network (DPN). The pipe network is in charge of distributing fluids from production plants to final consumers. Currently, these mostly consist of insulated, underground tubes.

- Terminal stations or collectors. Installed inside each building, they’re in charge of adapting pressure and temperature values for energy consumption according to the premises’ needs.

Keep reading: TES & District Heating: How to integrate heat pumps

How does district heating work

Simply put, district heating systems work by using a closed loop cycle in which heated water travels from the centralized production plant to each terminal station and then back to the DH plant.

A key aspect of how district heating works is the choice of heating sources.

Heating energy for these structures can be obtained from a variety of sources, including the burning of fossil fuels. However, the following heating energy sources provide more sustainable choices which can push modern cities’ efforts forward in order to meet decarbonizing goals:

- Energy from waste facilities (EFW). EFWs are power plants in charge of burning non-recyclable waste with the purpose of obtaining electricity and heat. The number of such facilities, which are pushing circular economy models for energy production, is growing across Europe. Copenhill is perhaps the most famous of all, in charge of treating around 400,000 tonnes of waste annually and producing electricity and heat for 150,000 homes, while also playing a part in the city’s leisure life.

- Waste heat from industrial processes. Residual thermal energy from industrial processes that would otherwise go to waste may be used for district heating.

- Cogeneration centrals. These facilities produce both electrical and useful heat energy. While traditional electricity generation using fossil burning could produce 60% rejected heat loss, cogeneration centrals enhance efficiency in energy production by using energy that would otherwise go to waste. Cold generation processes may also be incorporated, creating trigeneration centrals.

- Solar energy sources. These incorporate solar cells.

- Geothermal sources. Heat energy is extracted from underground sources, when available.

- Biomass and biogas. These may also be used as a source of energy for district heating.

- Electric boilers. In order to make these systems sustainable, wind or other renewable electricity sources must be used.

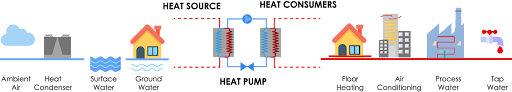

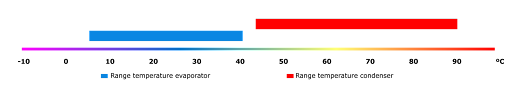

- Heat pumps. These structures generate an energy conversion process by using multiple heat sources, which include energy extracted from ambient air, water or the underground, sewage and wastewater, return water in district cooling or waste heat from industrial processes.

As such, they represent a very versatile option which can convert electricity to heat at high efficiencies: their coefficient of performance (COP) can reach values around four, resulting in a great resource optimization. Additionally, the US Energy department calculates that ducted air-source heat pumps can reduce electricity use for heating by approximately 50% compared to other structures, while geothermal heat pumps can reduce energy use by 30%-60%.

You may also be interested in: Heat pumps benefits in District Heating system

All in all, the choice of the most convenient heat source must be investigated by dedicated and expert engineers, as it may vary according to each area’s possibilities.

The evolution of district heating

District heating systems have evolved to increase efficiency and reduce energy loss through a series of 4 generations:

- First generation systems were developed at the end of the 19th century and used high-temperature water steam to distribute heat from electric centralized production plants.

- Second generation district heating structures evolved to replace steam with high-temperature water. This allowed for increasing security as well as the possibility to store spare energy.

- Third generation systems were born in the 1980s and are still the most common district heating solutions. Energy efficiency improvements were made in terms of isolating pipe systems as well as finding the alternative and more sustainable sources for heat described above.

- Fourth generation solutions are being developed today with the goal of minimizing heat loss issues as well as lowering temperatures in energy production.

Keep reading: District Heating Market Trends and Growth

6 benefits of district heating

1. Energy efficiency improvement

The centralized generation of energy translates into an improved efficiency in obtaining such energy. In fact, the ‘District energy in cities’ report by the United Nations Environment Program quantified operational efficiency gains of up to 90% and cited Helsinki’s CHP plants operating at 93% primary energy efficiency,

This is especially true for heat pump DH systems, where the maximum efficiency in hot water production and electricity consumption is achieved as proven by their high COP.

At the same time, the UN report claims DH systems facilitate decreases in primary energy consumption of between 30–50%, and cites the Paris network, which uses 50% less primary energy.

2. Cost reduction

District heating structures present lower operation and maintenance costs than in-building structures, which are typically hindered by their small scale but complex equipment and other related expenses (including upgrading needs, replacement pieces or insurances, among other costs).

Additionally, district heating systems using alternatives to fossil fuels benefit from an increased price stability, as they don’t depend on fluctuating prices.

3. A decrease in CO2 footprint

Sustainability is among the key benefits of district heating, which is guided by two possibilities:

- District heating systems facilitate the inclusion of renewable and alternative energy sources, as cited above

- Their increased efficiency helps reduce greenhouse gas emissions

In fact, the UN report cited above gathers some figures around district heating’s improved sustainability: the city of Milan reported savings of 2.5 tons of particulate matter, 70,000 tons of CO2, 50 tons of NOx and 25 tons of SO2 in 2011; Oslo avoids 500,000 tons of waste going to landfill annually and reduces the pollution equivalent to 150,000 cars driving 15,000 km a year in the city.

Discover: Sustainable heating technologies: how to make district heating more environmentally friendly

Again, in order to achieve a reduced CO2, the right heat source must be chosen. In fact, systems such as heat pumps can increase sustainability by cutting down CO2 and other nocive emissions.

4. Improved security

District heating systems guarantee a reliable and safe energy generation and supply, all while minimizing sanitary hazards and avoiding the need for flammable gasses inside buildings (unlike some traditional heating systems).

These structures also provide major improvements in air quality.

5. More useful space available

Centralized DH systems mean buildings can avoid the need for incorporating large equipment. The size of technical rooms is reduced and visually unpleasant elements eliminated as boilers and other equipment aren’t required.

6. Use of renewable and local energy sources

District heating structures allow for the incorporation of local and sustainable energy. These possibilities are expanded by including heat waste as a source and thus generating synergies between supply and production.

This, in turn, translates into the possibility of promoting increased city wealth, as local resources are used and employment is created for the design, construction, operation and maintenance of such systems.

Want to learn more about district heating and the current possibilities of these systems to decarbonize energy production and optimize costs?

Download our ebook ‘District heating: reference book’ and discover why this technology can be implemented in projects where decarbonization, energy efficiency, sustainability and operational costs are the main design factors.