Traditionally, the heating in homes and many commercial buildings has been provided by boilers burning fossil fuels. These methods were not only inefficient, but also have been responsible for the emission of substantial amounts of greenhouse gases. Many cities in Europe and throughout the world have begun to shift to the use of District Heating systems and are using biomass or combustible fuels. In recent years, these cities have also begun to implement heat pumps in their District Heating systems as they continue to move away from the use of fossil fuels. The main economic factors that are influencing the use of heat pump operations are:

- Cost of fossil fuels

- Cost of electricity

- Interest rates

- Efficiency of the heat pump system

- Simultaneous availability of heat supply and heat demand, simultaneous demand for heating and cooling

- Investment cost differences

Benefits of Using Heat Pumps

Figure 1: High-efficiency Industrial Heat Pump

Industrial heat pumps can offer an operational cost savings when the relative cost of fossil fuels and electricity is smaller than the efficiency of the heat pump. The energy savings and reduced emissions of heat pumps make them an attractive option for direct heating systems. The coefficient of performance for these types of pumps generally exceeds 1, or 100% efficiency, because they don’t just convert work into heat as many traditional heating sources do. Heat pumps also have the unique ability to draw heat from a heat source to where it is needed. They can use the air, ground, and even water as a heat source, they concentrate the heat from the source and use it to heat. Heat pumps can generate heat from water that is 4⁰C and operate near 300% efficiency. Heat pumps with capacities in excess of 100kW are considered large, however pumps are also available into the several MW range. They can provide heat output to about 70-90 ⁰C, which can put limitations on the use of these pumps in applications where high temperature output is required for certain applications or times. Industrial heat pump manufacturers are currently working on providing pumps which are capable of higher temperatures. In the meantime, heat pumps are best suited for direct heating applications where high temperatures aren’t necessary or to augment an existing heat source. They work perfectly for this application and are ideal for space heating and providing domestic hot water as well.

Heat Pumps and Thermal Energy Storage

Heat pumps can also be combined with Thermal Energy Storage (TES), a technology which stores and then allows for the transfer of thermal energy by heating a storage medium, such as water. The stored energy can be used later to provide heating. TES offers considerable potential to enhance energy management across many sectors by improving the use of heat, including waste heat, at varying temperature levels. Heat pumps can be used to extract the waste heat from the air or other processes very efficiently and that energy can be stored using TES to provide buffer storage so that excess thermal energy is available when needed; and to provide domestic hot water, space heating, heating or drying, and other on-demand heat applications. This allows the heat to be produced efficiently using the heat pump, perhaps when there is waste process heat available or outside temperatures are ideal and this heat can then be stored for later use. Thermal Energy Storage provides a sustainable solution for energy storage and supports the conversion towards an energy system based on more efficient and environmentally-friendly energy sources. TES can provide additional increases in efficiency throughout the system.

District Heating and Heat Pumps

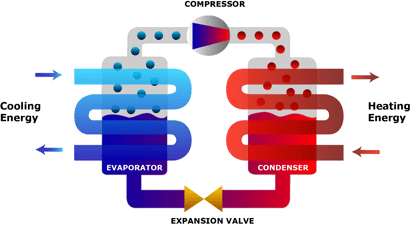

Figure 2: The heat pump cycle

Heat pumps are becoming increasingly popular in many cities in Europe because of their reduced emission of greenhouse gasses and the tremendous efficiencies which can be realized. The pumps do require some initial investment, however the operation and maintenance over the life of a this type of pump is less expensive than traditional boilers. Industrial heat pumps can also be used as a partial heating source in districts where higher temperatures may need to be achieved from time to time. The pumps can be installed in areas where it would be advantageous, for example to take advantage of waste heat or to provide space heating and can then be connected to the District Heating system to augment the system. Heat pumps may also be used to extract the heat from the return flow of the District Heating system and then that air is further heated by the district heat system, in this manner the heat pump can serve as a base load and a more traditional district heat source handles the peaks. A heat pump and district heat can also operate side by side. In a system with TES, the storage could potentially provide higher temperatures during times when the traditional district heat wasn’t operating.

Conclusion

The use of heat pumps in District Heating and Thermal Energy Storage continues to grow. As manufacturers continue to find ways to meet consumer needs, such as higher temperatures and greater efficiency in colder climates, these industrial pumps become more and more appealing. They offer unrivaled performance and significantly reduce the emission of greenhouse gasses, which is important these days considering ample local and international regulations. To find out why industrial heat pumps are an ideal complement to any District Heating or TES system, contact ARANER’s experts today!