The cooling demand in urban areas is increasing because of comfort requirements, heat island challenges and internal heat loads. The relatively high temperatures of the Middle East and Africa are other significant drivers of district cooling demand. We are at a point where Saudi Arabia and fellow emerging economies are looking at DC technology to serve their needs. In the midst of all these developments, the truth still lingers that adopting DC technology calls for a measured approach, whereby only the best components and equipment are applied. One area that every project manager must scrutinize carefully is industrial chiller quality. If you are implementing a district energy project, you may want to invest in a highly efficient industrial chiller. We have seen district cooling projects that use conventional chillers, for instance the older and small-scale ones. Challenges come in droves for such installations, ranging from unbearable greenhouse gas emissions to excessive primary energy consumption. You could unlock the highest potential of your DC system by using the highly efficient ARANER industrial chiller units.

District Cooling System Components

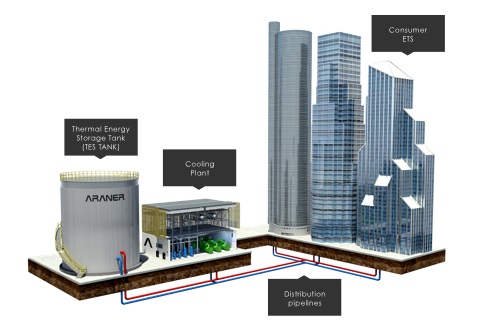

One way of identifying district cooling components is in terms of the following segments:

- Central chiller plant

- Distribution network

- Customer ETS: Energy Transfer Stations

Fig 1: District Cooling Components, ARANER.

Industrial chiller units are installed in the central chiller plant for production of chilled water. Electric grids globally conventionally suffer strain whenever the cooling demand is high. With district cooling option, grids enjoy some relief. Backed by efficient DC systems, major cities are seizing the opportunity and scaling their energy infrastructure with reduced fuel costs and healthier loads. Not counting, the capital expenditure cost savings on cooling setups for individual establishments. Several systems and technologies exist for optimizing District Cooling. One of the most basic approaches is to identify energy sources and find a dense cooling demand. Popular customer segments for this application are city centers, hotels, hospitals and retail centers.

Nevertheless, pursuit for optimum system performance doesn’t stop there. You can still enhance efficiency through implementation of thermal energy storage (TES), integrating energy production, proper maintenance, and retrofitting the chillers. At ARANER, we regard industrial chiller efficiency highly, similar to all the other options.

Industrial Chiller and Efficiency

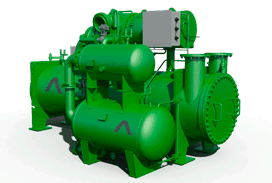

DC projects are capital intensive, so project owners look for ways to recoup this cost. Apart from applying economies of scale, the designers pursue component designs that promote energy efficiency. Relying on renewable sources of cooling water is also a viable strategy. Chillers are central to district cooling system configuration, unless the system is reliant on “free cooling” from oceans or deep lakes. Industrial chillers operate on either absorption or vapor compression refrigeration cycle to rid of heat from a liquid.

Fig 2: High-Efficiency Industrial Chillers from ARANER.

Waste heat is a byproduct of this cycle. Instead of releasing the heat into the ambient air, the chiller plant can be designed to recapture it for reuse, thereby increasing chiller efficiency in the process. Considering the importance of chillers for DC, it is important to select carefully, specifically to ensure high efficiency at both partial and full loads. This optimizes energy savings for the system. Chiller efficiency is derived from the relationship between cooling provided and energy consumed, but there are different rating methods. For instance, chillers powered by electric motors have efficiency given in terms of kilowatts/ ton of cooling. Absorption chiller efficiency is in terms of heat source (fuel/gas/vapor) consumed/ton of cooling. The point is that you want to ascertain the chiller has the required efficiency level when sourcing one for your district cooling project. While at it, it is worth noting that the manufacturer/dealer matters. Some providers are simply better than others are. Positive reputation borne out of years of experience and expertise is irreplaceable.

ARANER Industrial Chillers Offering the Best Performance

At ARANER, we provide high efficiency industrial chillers that can support different cadres of DC projects. With decades of experience coupled with continual training, our experts are capable of recommending and installing chillers for any district cooling project. Our prowess in customizing chillers to suit customer’s applications is renowned. If you are looking for the most energy efficient industrial chillers for your next DC project, be sure to contact the team. Get all the information you need and have all your queries regarding this technology answered by the experts. Even if you want the chiller delivered within a short timeline, you can rest assured that your search for a high efficiency chiller ends here.

Fig 3: Tailor-made Chiller adapted to project requirements by ARANER Engineers

The outstanding Emirates district cooling projects and many others globally are proof of what experienced engineers can achieve with high efficiency industrial chillers.

Conclusion

When you decide to install a district energy system, you are obviously expecting a reliable, energy efficient and environmentally friendly option. You can only enjoy all the dc system advantages if you execute this project professionally. The chiller, like any other major component of the district energy system, must meet efficiency requirements, alongside other standards. You will find numerous industrial chiller manufacturers out there, but ARANER offers standout quality. Are you interested in detailed information about robust industrial chillers for new installations or retrofits? Contact us today.