Heat generation is a common byproduct of many industrial processes, even high precision and high-speed operation technologies, , leading to the need for effective cooling solutions. Servers, variable frequency drives, spindle motors and other countless components need perpetual or regular cooling to perform optimally.

HVAC systems systems alone can account for a significant portion of a facility's energy consumption, easily can consume up to 30% of the total energy. Industrial facilities can use more than this, especially if they feature substantial process loads.

Instead of having a risky refrigerated system or traditional refrigeration systems, installing an energy efficient chilled water system for your next big project is an excellent idea. You can save up to 40% of energy in the process. Let's explore why and how.

Chilled Water Systems- Applicable in numerous projects

For a long time, chilled water systems have been integral to large-scale HVAC solutions, effectively transferring heat from high-load areas to a refrigeration system or condensing loop. This cooling method comprises of several components as below:

- Compressor

- Heat absorption- evaporator

- Refrigerant piping (for evaporative cooled or air-cooled system) or condenser water piping (for water-cooled system)

- Heat rejection – radiator or cooling tower

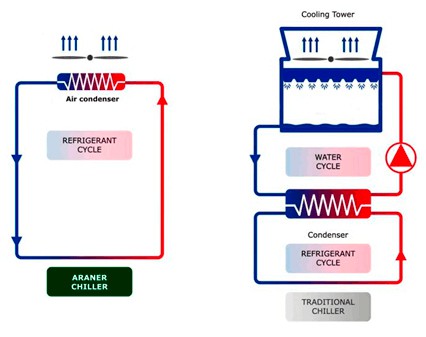

Fig 1: Water Cooled and Air Cooled Chillers

In addition to these primary components, chilled water systems incorporate various supportive elements such us controls, pumps, refrigerant/ water treatment, filtration devices and air eliminators/ air separators. These systems find applications in both commercial and industrial settings.

Large commercial buildings, campuses, industrial facilities, and similarly large sized projects require chilled water systems for their cooling equipment. Industries are faced with stringent EPA control requirement and worsening utility cost situations. In a bid to reduce these costs and comply with requirements, they are turning to chilled water systems.

The cooling system transfers heat from production processes and industrial equipment. Two most notable components in these applications are chiller (cooling unit), that collects the heat gained from the processes/equipment, and heat exchanger, that enables the plant equipment and production processes to lose heat to the cooling water. This heat can be lost through either a closed loop system or the atmosphere (via cooling towers).

If you have any of the following projects, the best chilled- water system could come in handy:

- Power generation

- Pharmaceutical

- Refinery- gasoline, ethanol, biodiesel

- Manufacturing

- Food and beverage

- Petrochemical

Araner, experts in Chilled Water Systems

In most cases, designers only give the project attention only in the initial stages of operation. But at ARANER, we understand the critical role that reliable chilled water systems play in ensuring comfort and efficiency in buildings.

To determine the best design practice for long term service of the system, ARANER analyses how various system components respond to present and future factors. For instance, the team seeks to know how coils are affected throughout the life of the system. For successful analysis, modern software is used and parameters modified.

Our approach goes beyond the initial design phase to ensure long-term performance and adaptability. Through advanced simulations, we analyze how system components will respond to present and future factors, ensuring optimal performance throughout their lifespan.

We recognize that factors like fouling and friction can affect system efficiency. As air and water contact the coils, scale and particulates form on the surfaces. Fouling hinders heat transfer and reduces efficiency of the system. Our simulation processes allow us to address these issues proactively, optimizing system performance and minimizing energy losses. For a big project, seemingly small factors can translate into large losses. Moreover, the weather can be a hindrance, especially if your project is in the tropics.

With decades of experience in commercial refrigeration projects, we offer solutions that deliver highly efficient systems, whether through new installations or improvements to existing ones.

Design for up to 40% savings

Achieving significant energy savings requires a comprehensive approach. With many years’ experience in commercial refrigeration projects, ARANER is able to apply the expertise and knowledge gathered to offer solutions that will ensure highly efficient systems. This can be achieved through a brand new installation or improvement of the existing one, whichever our analysis and your decision will lead us to.

At ARANER, we focus on optimizing every aspect of the chilled water system, from pump efficiency to Thermal Energy Storage (TES) installations. By minimizing energy usage and maximizing efficiency, we help our clients realize substantial cost savings.

Pomping system

The pumping system is a crucial component in cold water systems, and at ARANER we focus on maximizing its efficiency to reduce energy consumption. Our experts design pumping systems with optimal configurations, adjusting pressure settings to the lowest possible value and appropriately programming their operation. Additionally, we ensure pumps are properly maintained, including lubrication, alignment, and maintaining positive suction pressure.

Thermal Energy Storage (TES)

Thermal energy storage (TES) is a critical strategy for maximizing the efficiency of chilled water systems. At ARANER we implement TES systems that allow us to take advantage of lower energy rates at night to cool and store water, which is then used to meet demand during the day, when energy costs are higher. This not only reduces operating costs, but also reduces the load on the electrical grid during peak hours. TES systems are especially beneficial in large-scale projects, where energy demand can be considerable. With our experience in the design and implementation of TES systems, we help our customers achieve significant energy cost savings and maintain the efficiency of their cooling systems over the long term.

Fig 2: A TES Tank for Chilled Water

Other solutions towards savings of up to 40% are:

- Optimizing pump settings and scheduling.

- Implementing TES to take advantage of off-peak energy rates.

- Investing in water treatment systems and monitoring flow rates.

- Regular maintenance to prevent issues like Low Delta T Syndrome, a system problem that leads to inefficiency.

Conclusion

From design to implementation, ARANER has the expertise and capabilities to handle projects of any size. From laying of kilometers of pipework, to swift chiller efficiency replacements, to the installation of reliable chiller plant, the team at ARANER has all under their sleeves.

Our focus on efficiency and cost savings ensures that your project not only meets its cooling needs but also reduces energy consumption and operational costs. For more information about our chilled water system services, contact us any time.