The original design of an absorption chiller is credited to the likes of Ferdinand Carré, Carl Munters and Baltzar Von Platen, renowned scientists who did their works between the 1850s and 1920s. While the products were first produced commercially in 1923, it was only in the 60s that serious production started due to rising demand for caravan refrigerators. The legendary contributions of these men are still visible today — they are playing a crucial role in district cooling systems. Their early innovations laid the foundation for a cooling technology that, over time, has evolved into a cornerstone of modern sustainable cooling solutions.

Recently, research and development in absorption cooling technology has increased due to higher interest in decentralized energy systems and the ever-tightening energy efficiency regulations. Governments around the world are pushing for reduced carbon emissions and energy consumption, making absorption systems even more appealing. Technological advancements have also enhanced the efficiency, reliability and operational flexibility of modern absorption chillers, enabling their application across a wider range of industries, including healthcare, hospitality, data centers and food processing.

Absorption chillers have proven to be ideal replacements for compressor chillers in places where power is unreliable, unavailable or costly, where waste heat is available, or where restrictions on noise deem compressor chillers useless. In areas with limited access to a stable electricity grid, their reliance on alternative heat sources rather than mechanical work gives them a decisive advantage.

What is an absorption chiller?

Every chiller relies on some external force to transfer heat to a high temperature medium from a low temperature one. For instance, electric chillers have compressors. Absorption chillers replace the compressor with steam, hot water or any other external heat source. An absorption chiller has a very straightforward operation. Its operation is fundamentally similar to what happens in a vapor compression chiller in that both processes involve condensation and evaporation of the refrigerant within the system.

Absorption chillers vs. Compression chillers

While an absorption chiller uses a thermo-chemical process, a conventional chiller relies on mechanical energy. They only difference is how the increase the pressure of the refrigerant from evaporation level to condensation level. Simply put, the absorption chiller does not compress refrigerant vapor; instead, it dissolves the vapor in an absorbent, and transfers the resulting product to higher-pressure environment using a pump with a very low electricity consumption. Of course, this only a description of the basic absorption cycle —there are more complex cycles that even have extra components.

Working principle of absorption chiller

Some substances have the peculiar property of having affinity for other substances at certain pressure and temperature conditions, only for this affinity to change if the conditions are altered. Michael Faraday came up with the idea of the absorption chiller based on this concept in 1824. The principle behind an absorption process is to separate and recombine to fluids (refrigerant and absorbent) to create a cooling effect. Usually, absorption chillers are either NH 3-H 20 (ammonia-water) cycle or LiBr (Lithium bromide) cycle. In the first cycle, water acts as the absorbent while ammonia water solution acts as the refrigerant. In the latter cycle, lithium bromide is the absorbent and water is the refrigerant. Most industrial chillers use the ammonia-water vapor absorption system because of the following benefits:

- High solubility of ammonia in water.

- Ammonia water absorption chiller works with positive pressure (Li-Br works with negative pressure) reducing maintenance problems and making the machine to be more robust

- Ammonia water absorption chiller can work with extreme conditions (high condensation temperature and low evaporation temperature).

- Able to cool glycol at negative temperatures.

- Compatible with air cooled condenser (zero water consumption).

Discover: Industrial Chillers for DCPS: efficiency analysis

How do absorption chillers work: step by step explanation

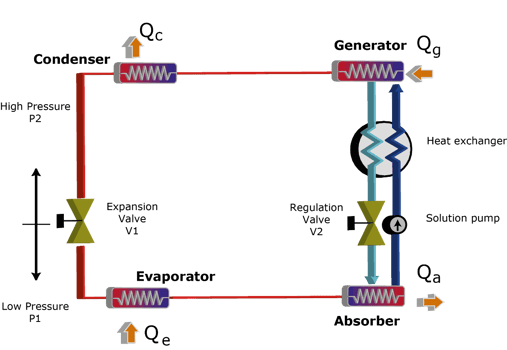

Representation of a simple absorption refrigeration cycle

- Generator: in the generator, a heat source produces ammonia vapor from a strong ammonia solution. Before the ammonia (refrigerant) vapor enters the condenser, it passes through a rectifier for dehydration.

- Condenser: the now dehydrated and high-pressure ammonia enters the condenser where it is condensed. After cooling, it goes through a throttle valve (expansion valve) and pressure and temperature is reduced. The new values must be below what the evaporator (next stage) maintains.

- Evaporator: the evaporator, which is essentially the cold refrigerated space, appears now. The cooled ammonia enters the evaporator, absorbs heat and then leaves as saturated ammonia vapor.

- Absorber: as the vapor enters the absorber, it is exposed to a spray of weak ammonia-water solution. The weak solution in turns becomes a strong solution. The pump directs the new solution to the generator through the regenerator (may also be referred to as heat exchanger). By the time the solution arrives, it has already attained generator/condensing pressure. The process starts again.

To grasp the process, let us go step-by-step, starting at the generator. Other components of this chiller are the condenser, the absorber and the evaporator. The idea behind this process is the creation of a liquid solution with the refrigerant that can be pumped to a higher pressure level. This pumping process, is a replacement of the mechanical compression that uses electrical power.

Generator

The warm dilute solution enters the chamber, which is at a higher pressure. The solution is sprayed over the heat exchanger carrying hot water or any other heat source. Heat transfer occurs and the solution boils, thereby releasing refrigerant vapor and a hot concentrated solution.

Condenser

The refrigerant vapor goes to the condenser, where it is converted back into a liquid by the cooler heat exchanger. The next stop for the liquid refrigerant is the evaporator, but it has to pass through an expansion valve first, so that temperature and pressure can drop.

Evaporator

The refrigerant enters this section at low pressure as a mixture of liquid and vapor. The purpose of this section is to chill. For commercial applications, the evaporator chills the water for cooling via the building HVAC system.

Absorber

After being vaporized in the evaporator, the refrigerant enters the absorber. The absorber has a strong solution, it simply absorbs the refrigerant vapor, and it is diluted. The resulting heat is discarded to the atmosphere via the cooling water.

It may interest you: Industrial refrigeration maintenance: Best Performance

Absorption refrigeration system in combination with combined heat and power (CHP)

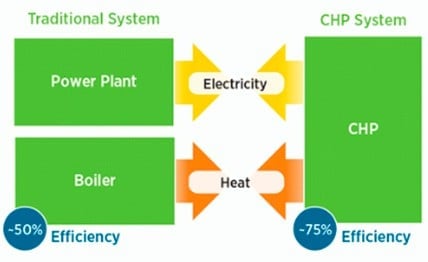

As energy prices skyrocket, power production and the point of use has become more reliable and affordable than supply from a far-flung power plant. A local Combined Heating and Power (CHP) plan is bound to be not only more energy efficient, but also more energy friendly because it produces less greenhouse gases. The CHP system is characterized by the concurrent generation of useful thermal energy and mechanical power/electricity from a single energy source. It is also referred to as a cogeneration system.

Fig: Process Flow Diagram of a CHP System

Fig: Process Flow Diagram of a CHP System

Absorption chillers rely on heat energy to chill water, so they make a perfect combination with CHP systems. Combining an absorption refrigeration system with a cogeneration plant allows for the usage of excess heat. The plant produces hot water, which in turn drives the absorption chiller. The concept of this technology (also called “trigeneration”) is borne out of the concurrent need for chilling, power and heating in the same facility. A wide range of facilities has such a need for example, shopping malls, the food industry and hospitals. There is one requirement for chilling and CHP to work perfectly- the end users need to be in the proximity of the plant because distribution of chilled water is costly as compared to electricity. Return on investment starts to emerge during seasonal periods that allow for the maximum utilization of the waste heat produced by the power plant. For example, this system exhibits flexibility by offering cooling during summer and for heating in winter. This way, running hours are maximized for the benefit of the environment and facility owners.

Keep reading: Chilled Water System on your next project: save up to 40% of energy

Absorption chillers: get the best from them!

While absorption chillers are an improvement to the conventional cooling methods in the ways we have already enumerated, proper and regular maintenance is necessary for optimal performance. This is the only way to ensure the equipment reaches its 25 years lifespan. A chiller will work perfectly if technicians focus on these maintenance areas: controls, mechanical components and heat transfer components. Here are some of the areas that need attention:

- Pump shaft seals- check for wear

- Refrigerant leaks- loss rate shouldn’t exceed 1%

- Heat transfer surfaces- should be free of sludge and scale

- Heat exchanger tubes – cracking, pitting and corrosion are undesirable

- Pump bearings- replacement or cleaning may be necessary

Choosing the best absorption chiller

You may perform all the above maintenance procedures, but the equipment still to deteriorate and the maintenance costs increase. That might be the time to upgrade to a modern, more reliable and more efficient machine. If the system is working at part load for long periods, choosing a chiller with high part load efficiency may be all you need. It is also important to size the chiller correctly. A chiller that is oversized for a certain application will easily operate at a low efficiency. It could even develop serious problems if it runs for extended periods under such loads. Let thorough analysis of the operational needs, facility type and schedule define the chiller upgrade/selection process.

It might interest you: Industrial Process Refrigeration: An In-Depth Look at Each Component

Absorption chillers: all its benefits!

We touched on this slightly at the start of this post. Going by the description of the operation and requirements of absorption chillers, the following are scenarios where the chillers would be preferable.

- High electricity costs and low fuel costs. Make sure the differential is huge enough.

- There is no enough electrical power available.

- Waste heat is available (for example from exhaust flow or hot water from engine jacket).

- Availability of enough hot water or low-grade waste steam.

It will also suit areas where a quiet environment is the priority —an absorption chiller is quiet, wear-free system due to lack of moving parts— minimal maintenance requirements.

Araner, experts in absorption chillers

Are you still wondering, “ how do absorption chillers work?”. As ARANER, we have been performing cooling and heating load analyses for many years, so they can help. If you are considering installing an absorption chiller, it is worthwhile to conduct a feasibility study before injecting your money into a huge project. Such a study will show whether indeed there are any economic and environmental advantages. Absorption chillers work in a manner that justifies them where peak electricity demands are high. Using heat recovery is another opportunity for cost savings for facility owner as we have described. Get in touch with the team for guidance and support.