From the beginning of industrial refrigeration, when in the nineteenth century the first systems were developed for applications related to the food industry, until today, where the applications are increasingly diverse (District Cooling, Electricity Production, and Data Centers, amongst others), a common interest has always been maintained: supply the necessary cooling capacity in the most efficient and safe way. Many of the problems related to the failures of security in the refrigeration systems, in any field, usually come given by the lack of knowledge, either when designing, installing or using the equipment. Knowing the refrigeration systems well, whose basic principle of operation is the same regardless of the sector of application, will help us to be able to decide which solution best suits our needs. In ARANER we never forget any of the principle steps. Keeping that in mind, in our eBook we discover together how refrigeration works and the important parameters to be taken into account.

Compression Cycle or Absorption Cycle?

Compression and absorption cycles looks very similar in principle but they are different in the way the refrigerant pressure is increased. In compression cycle, the refrigerant pressure is increased in a pure mechanical way; while the increase of pressure in and absorption cycle involves several thermo-physical processes. The decision of using one or another cycle depends on the availability of heat and electricity resources principally. Absorption is advisable when low cost heat can be obtained, most often the residual heat from some other process.

Refrigerant Selection

The refrigerant should be a fluid capable of operating in the conditions proposed by the refrigeration cycle. The selection of the refrigerant for each situation would depend on its particular conditions with the lowest possible environmental impact. For this reason, there are some refrigerants already banned or with limited use by the authorities. The refrigerants are sorted mainly into two scales based on their environmental rating: Ozone Depletion Potential (ODP) or Global Warming Potential (GWP).

High-Level Components for an Industrial Refrigeration Solution

The Refrigeration Compression Cycle involves four main components: compressor, evaporator, condenser and expansion valve/throttle valve. The compressor is the dynamic part involved in the refrigeration cycle. It is the element that adds energy to the system in accordance with the Thermodynamics Laws. For the refrigerant to transfer energy with the other systems involved, a wide range of heat exchangers could be used. The cooling energy is produced in the evaporator, where the refrigerant is evaporating by absorbing heat from the media. The compressor increases the pressure of the refrigerant up to the condenser pressure, so the refrigerant is able to exchange heat with the ambient air or other fluids. Then the refrigerant is expanded in the expansion valve so the pressure is reduced up to the evaporating pressure and the cycle is closed. A proper selection of the components ensures a good performance, as you can check in our eBook.

Unique Heat Rejection Solutions

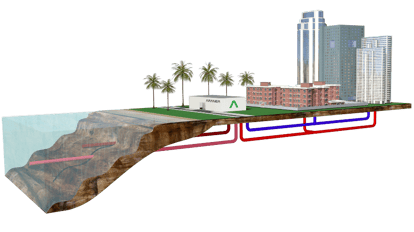

Refrigeration means extracting heat from one system. Therefore, heat should be rejected into another one, which is often the environment. This makes the heat rejection a crucial part in a refrigeration system that will not only depend on the individual physical constrains (location, weather), but also should take into account the environmental and legislation limitations. In spite of the complexity that certain operating situations can present, especially in the areas of the planet where the environmental temperatures are high (like Middle East), all the projects need to be optimized and always reach the maximum efficiency. ARANER selects the suitable heat rejection technology (sea water, air cooled, and cooling tower) for each particular project and integrates it within the contour conditions. Find out more information in our eBook!

Figure 1: Sea Water industrial cooling solution

ARANER's Expertise in Industrial Refrigeration Projects

While it is true that the principle of operation is common in all refrigeration systems (extracting heat from a system, it is also true that the technical solution required by each and every industry is unique. This fact makes necessary the appearance of specialized companies such as ARANER, experts in tailor-made solutions.

Conclusion

Having in mind how crucial is to have a clear and reliable idea of how the Industrial Refrigeration market works, ARANER has compiled a brand-new, high-level Industrial Refrigeration Reference EBook with the necessary information needed to understand the working principles and new trends of the Industrial Refrigeration market. This EBook details the operation of the refrigeration cycle, an analysis of the different types of refrigerants, the latest technologies used for heat rejection, and the most relevant applications of industrial refrigeration equipment. Fill out the form below to receive your eBook for free!