Regardless of the important changes that the energy industry is going through these days, natural gas-fired power plants continue to be on the rise after many years. Gas turbine power plants are a popular choice for power production and manufacturing industries, as they offer lower costs, greater efficiency, and lower carbon emissions than other options. However, the efficiency and power output of gas turbines decreases as ambient air temperatures increase, as demonstrated in this video. This loss of power and efficiency in large warm areas can be very problematic when dealing with critical facilities where every second count.

Fortunately, there are several affordable technologies that can help power producers to avoid this output drop, improving their profitability and guaranteeing constant power production during peak hours, with a moderate investment. Continue and find out what are these technologies!

Turbine Inlet Air Cooling - TIAC

Turbine Inlet Air Cooling (TIAC) involves cooling the air flow entering the gas turbine when the weather is hot, which usually coincides with the hours of peak demand. This is highly prevalent in the Power Industry in the Middle East, where day-time temperatures far exceed night-time temperatures throughout most of the year.

Figure 1: A Turbine Cooling installation at a Power Plant

Figure 1: A Turbine Cooling installation at a Power Plant

How does TIAC improve gas turbines? The cooler air increases the airflow through the combustion chamber, increasing the rate of combustion. Increased combustion results in increased power output and improved efficiency of the turbine. The actual power recovered varies by individual application, but some installations have achieved increases of up to 40% using this technology. Turbine efficiency improvements are also frequently near 30%. TIAC also reduces the heat rate of the turbine by about 5%, meaning that the fuel consumed to produce the same power output is 5% lower with this system. This feature makes TIAC a proven green technology with carbon credits, and so a popular option for those with environmental concerns while needing additional power and higher efficiency. Turbine cooling technologies like TIAC offer improvements for both new and existing gas turbine power plants. It is compatible with nearly any turbine or process and more affordable to install than an additional turbine. Besides, the time required to construct a TIAC system is shorter compared to a new gas turbine delivery; one of the reasons? At ARANER we can design these systems as both modular and/or skid-mounted units requiring minimal setup and installation.

Thermal Energy Storage - TES

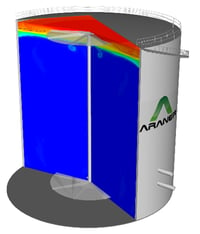

Figure 2: A Thermal Energy Storage tank with natural water stratification

Figure 2: A Thermal Energy Storage tank with natural water stratification

A Thermal Energy Storage (TES) system offers the opportunity to generate energy during off-peak hours and store that energy to be later used during on-peak hours, allowing operators to balance supply and demand.

Let’s break down the TES process: These tanks stratify the water naturally, with warm water on the top and cold water on the bottom. Due to this natural stratification, warm water enters and exits out the top of the tank, and cold water enters and exits via the bottom. View a short video of this process by clicking here.

A TES system like those designed by ARANER results in less wasted energy, cost-savings, versatility, and reduced stress on the power grid. Most of these benefits directly result from shifting generation from times of peak demand to off-peak demand. TES provides an ideal opportunity to meet small, intermittent cooling loads where they exist, increasing the efficiency of chillers at reduced capacity and thus contributing also to reduce carbon emissions. Furthermore, TES can serve as a backup system during a power or equipment outage like in this Data Center Case Study.

TESTIAC - The Combination of TES and TIAC

Thermal Energy Storage applied to Turbine Inlet Air Cooling (TESTIAC) is an innovative combination of the two previously discussed technologies. While TIAC provides an increase in overall power augmentation and efficiency, TES allows for the storage of energy created during off-peak demand periods (energy is cheaper), for its use during peak demand periods (energy is more expensive). This way TESTIAC provides an excellent solution where different electrical tariffs or heavy production variations affect the cost of production. Discover 3 benefits of a TESTIAC system for your GT Power Plant in this post.

Conclusion

Power augmentation and increased efficiency of gas turbine power plants are both achievable and affordable without the need of installing additional power. Your Gas Turbine Power Plant will run better than ever if you employ TIAC or its innovative combination with Thermal Energy Storage called TESTIAC. The experts at ARANER can help you determine which power augmentation methods are best for your facility – we perform a full analysis and accompany you through the entire process from start to finish. Trust in us – we have great time-tested experience at increasing power output and efficiency in gas turbine facilities in warm areas using these technologies.