Climate change and clean energy issues have made the world such an uncertain and dynamic place. Governments and everyone else concerned are constantly looking for the way forward in the power generation industry. In the midst of this entire mere, focus on enhanced power efficiency remains crucial. Enhancing efficiency of the existing power plants can achieve a lot in terms of reducing emissions, conserving resources and reducing generation costs.

Main Problems of the Sector to Increase Its Productivity

Estimates show that the global demand for electricity is growing steadily and will hit 38,700 terawatt-hours within three decades. With this massive increase comes escalated demand for fossil fuels. Fossil fuels cater for 81% of global electricity, a level that has remained unchanged for three decades. Coal is still holding a substantial share of this portion, and in fact, its use is increasing in some regions- non-OECD countries. Global carbon dioxide (CO2) emissions caused by humans continue to grow, mainly because of power generation. Improved operations could help avoid these emissions. Such interventions include installing modern power generation solutions and improving operations in coal fired power plants. Some of the problems the sector must tackle to increase productivity are:

1. Enhanced Power Plant Efficiency

Power plant efficiency is not difficult to determine, yet only a few facilities are committed to this exercise. Often, the problem is lack of expertise and test equipment or instrumentation.

2. Risk of the Solutions

While efficiency improvement is generally a positive solution, there are cases it is perceived to put electricity regulators and power plant operators at risk. The best solution in that case is to conduct a thorough risk analysis, including calculations of whether the solution is profitable.

3. Financing Challenges

Many utilities are interested in enhancing thermal efficiency, but financial incentives for the expensive processes are hard to come by. This is especially a challenge when the consumer will take the brunt of fuel costs.

ARANER Customized Solutions

When it comes to filling the gas in the power generation industry, Araner has done an incredible job. We can group the solutions as TIAC, TESTIAC and TES. TIAC refers to Turbine Inlet Air Cooling while TES refers to Thermal Energy Storage. TESTIAC is a combination of the two solutions. These solutions add value because gas turbines (GT) are central to the power generation industry. GT technology offers low CAPEX and a short delivery time. Addition of Heat Recovery Steam Generators (HRSG) technology at the GT exhaust offers high efficiencies. Unfortunately, a challenge develops when you take this setup to extremely hot climates. The ambient temperature reduces turbine power output and efficiency. Using TIAC, Araner is able to contain this problem. TES is the storage of chilled water generated during off-peak periods. Storage is in a Stratified Thermal Energy Storage (TES) tank and has many proven benefits, including optimization of inlet chilling.

Repowering

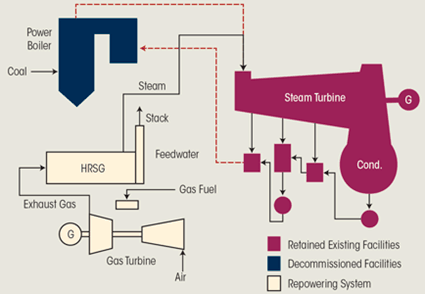

Repowering involves removal and replacement of the steam generation section of a power plant and in its place putting Heat Recovery Steam Generators (HRSGs) and combustion turbines (CTs). The new gas fired machine produces steam, which goes to the steam turbine for electricity generation. Replacement of the obsolete technologies means that still-relevant components are retained for effective usage of the existing plant. Here are some benefits of this method:

- Better environmental performance

- Improved generation economics

- Longer power plant life

- Enhanced maintenance and operation

- Increased power output and efficiency

Repowering comes in handy for existing coal- or gas/oil-fired power plants in certain conditions with the aim of making the plants competitive in terms of costs. The parameters are measured alongside the benefits we have listed above.

Different Options for Repowering

The gas turbine can be repowered using the following technologies:

- Heat recovery repowering

- Feed-water heater repowering

- Hot wind-box repowering

- Site repowering

Schematic Diagram of Heat Recovery Repowering

Repowering, also called uprating, is a reliable power enhancement technology for existing power plants, for instance combined cycle power plants and simple-cycle gas turbine. More intelligent configurations and technologies are used while the type of plant is maintained. Some of the technologies that can also be used to improve the performance of old steam power plants are:

- Repair

- Retrofit

- Rehabilitation

- Cogeneration

Power plant improvement can significantly reduce harmful emissions and increase profitability. Solutions come in all forms, ranging from simple methods to long-term solutions. Araner aims to help utilities achieve continuous improvements that will enhance efficiency by implementing best practices and using latest technological solutions. Contact us if you would like to learn more about any of these technologies for the power generation industry.