The Power Generation industry is driven by efficiency, and recent industry trends, as well as trends looking beyond 2020, reflect that. The use of renewable energy and natural gas is becoming popular at power plants across the globe, and these trends, among others, offer opportunities for innovation. Moreover, there are prevalent issues that the Power Generation industry has yet to tackle, such as growing demand for energy and fossil fuels in addition to rising emissions. For players operating in the industry, efficiency and innovation at every point is an absolute necessity. Gas turbines, a common source of power generation, have become a focus regarding the efficiency challenge. In this post, you will learn an overview of gas turbines, factors affecting performance and efficiency, as well as innovative turbine solutions. For a more in-depth look at the Power Generation industry and gas turbines, download our free compilation e-book.

Types of Gas Turbines and Power Plants

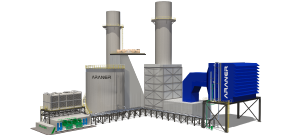

Figure 1: A Gas Turbine Power Plant

Many times, it’s necessary to determine if a gas turbine is really the right fit for your power plant. Gas engines are a typical alternative to gas turbines, and gas engines are usually used in smaller projects. Gas turbines tend to be a better fit for bigger-scale projects. Typical turbines include aero-derivative gas turbines and industrial gas turbines, with common turbine manufacturers being Siemens, General Electric, Ansaldo, and Mitsubishi. For power plants, the choice is often between open or combined cycle gas turbines. Each power plant’s needs are different, so you must really understand the theory behind each option to make the right choice. For an in-depth look at the pros and cons of each type of turbine, read the Power Generation and Gas Turbines eBook.

Performance and Efficiency of Gas Turbines

Figure 2: Industrial gas turbine

Gas turbines are only about 60% efficient in current industry conditions, although experts predict this percentage to rise slightly by 2020 . The performance of gas turbines is dependent on a variety of issues ranging from high temperatures and humidity to losses and fuel. The fact is, unless you do a proper study of your GT Power Plant, systems, and turbines, you risk huge inefficiencies. Especially for plants operating in high ambient air conditions like the Middle East, your gas turbines will suffer reduced power output in extreme heat or humidity. As average temperatures are rising steadily each year, this is a problem that needs to be tackled NOW. But how?

Gas Turbine Solutions: TIAC and TESTIAC

Luckily, there are several innovations available to increase turbine performance and efficiency: Turbine Inlet Air Cooling (TIAC) and TIAC combined with Thermal Energy Storage (TES).

Figure 2: TESTIAC configuration for a power plant

A Turbine Inlet Air Cooling system is the perfect innovation for combatting hot and rising temperatures. TIAC provides a stable air temperature to the inlet air of the turbine, allowing for power augmentation and increased turbine efficiency. If you don’t have the capacity to install another turbine, or you do but prefer a more cost-effective solution to increase both power output and profits, TIAC provides the perfect opportunity for your GT Power Plant. There are many different varieties of TIAC systems depending on your needs, with technologies like wetted rigid media, fogging, wet compression, chillers, etc. TESTIAC is the combination of TIAC and Thermal Energy Storage (TES). The incorporation of a TES Tank into your GT Power Plant allows for cooled water to be generated during off-peak hours and used to cool the turbines. There are many benefits to this type of combination, including smaller load sizing, reduced capital, and operational costs.

Conclusion

Gas Turbines and GT Power Plants are the future of the Power Generation industry. They still present the most reliable and efficient solution for power generation, and with innovative solutions like Turbine Inlet Air Cooling, they will continue to lead the industry in 2020 and beyond. If you’re interested in gaining efficiency and power output, go with TIAC! To discover the steps you should consider when incorporating TIAC or TESTIAC into your plant design, discover our new e-book on Power Generation and Gas Turbines. Otherwise, talk to us directly!