Piping stress analysis is a very important and intricate task that is carried out in the design of piping systems. This type of calculation has been implemented for decades, initially by a group of highly specialized engineers which used hand calculations and their vast experience in piping system behavior.

This was revolutionized in the 70s and 80s with the introduction of computers into the scene, greatly facilitating this analysis. But nowadays it is still a crucial method to determine how your piping system will behave under difficult conditions and avoid future problems.

In this article we will learn why carrying out a stress analysis is crucial to your system, where this analysis fits in the piping system design process and why ARANER can be your trusted collaborator in carrying out this process.

The why and when of piping stress analysis

A piping stress analysis is required when a piping system is determined critical, this is usually dependent on the following parameters:

- System pressure and temperature.

- Pipe nominal diameters.

- Equipment connected to the system.

- Fluid in the system.

As for why a piping stress analysis is a must in every critical piping system, here are the reasons why you should pay attention to stress analysis:

- To verify the structural integrity of the system: by making sure that the system maximum tension stays under the limits of the applicable standard or code.

- Guarantee a continuous operation of the system: by focusing on the equipment and elements connected to the system, and preventing failure associated with these.

Methods of analysis

Currently piping stress is calculated using computational programs which use either a finite element method or a more simplified, but equally effective, truss model. These computational programs enable a larger group of engineers to perform this analysis; however understanding and analyzing the software output is critical to obtain the desired results.

Here at ARANER we have highly knowledgeable piping engineers with 10+ years of experience in the sector to ensure that all the objectives of the piping stress analysis are met.

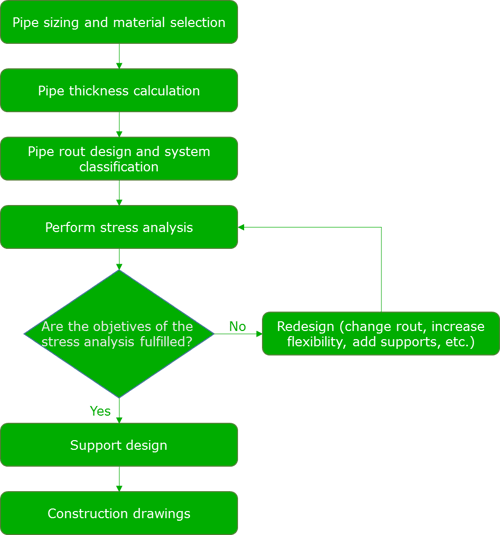

Finally to illustrate where this analysis fits in the global design process of the system in order to achieve an optimal and safe piping system we may observe the following steps:

Of course, we adapt to every project to perform the best stress analysis and evaluate correctly every case. If you need help evaluating your piping system, ARANER can assist you in doing so.

Conclusion

For all the above-mentioned reasons, performing a piping stress analysis is a vital piece in the puzzle of designing a safe and efficient piping system. Not performing this analysis properly may mean future problems in your piping systems in the long term.

If you need additional help with your piping project or any other solutions related to energy systems get in touch with an ARANER representative for assistance.