Seawater heat pumps represent one of the leading efforts in achieving maximum efficiency in heating and cooling systems. The current context is seeing a series of endeavors to increase sustainability and achieve decarbonization in the building sector and the energy consumption related to urban heating and cooling systems.

This is accompanied by related national and international regulations, such as the Renewable energy directive (RED) in the European context, targeting greenhouse gas (GHG) emission reduction goals.

As the building stock in the EU has been found to roughly be 75 % energy inefficient, leading to undesirable energy waste, both private developers and public institutions are looking to reduce total energy consumption and CO2 emissions linked to this area.

In such a context, heat pumps have offered a series of proven benefits to decarbonize the building sector, as associated CO2 emissions decrease to zero when paired up with renewable electricity sources (Thomaßen, et al., 2021).

The use of seawater heat pumps can thus provide a key role in generating cleaner heating and cooling models and moving forward towards carbon-neutral cities.

At Araner, we’re fully aware of the potential of this technology and have worked in implementing heat pump-based structures across a wide array of pioneer projects.

As such, we’ve compiled a short guide about seawater heat pumps that includes a definition of this technology, as well as a look into how exactly they can increase efficiency for buildings’ heating and cooling systems.

What are seawater heat pumps

A heat pump can be defined as a mechanical device in charge of transferring heat from a low-temperature source to a high-temperature source. In order to do so, it uses an external energy source.

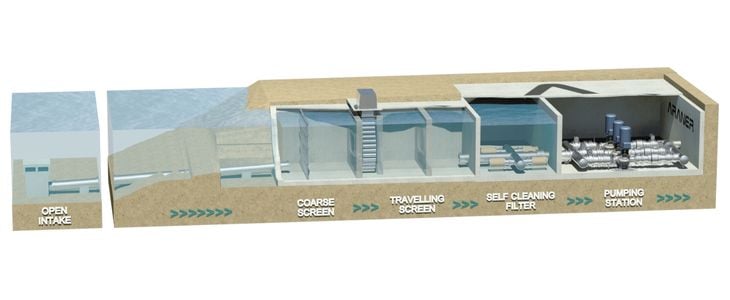

In the case of seawater heat pumps, the system uses seawater as a source of heat, then transferring it through the use of electrical energy input in order to heat and cool building, through districts energy systems.

The primary reason to employ seawater as a source is that the sea typically enjoys stable temperatures (at particular depths) throughout the year, as opposed to other heat pumps using air as a source (more prone to temperature changes).

In winter, seawater heat pumps can pump heat from the ocean while, in summer, heat pumps can use seawater as a source for cold. However, each location of seawater heat pumps will present particular needs and challenges: the needs for a project in the Nordic and Mediterranean seas will greatly vary.

The result is emission-free and reliable cooling and heating energy that has already been successful in a number of projects. For instance, Monaco has been experimenting with seawater heat pumps since the 1960s and is now developing a project where 7000 housing units will be able to enjoy carbon-neutral energy by 2025.

Seawater heat pumps components

- Working fluid: it enables heat transfer by absorbing, transporting and releasing heat through its circulation through the system. It’s manipulated by increasing or decreasing pressure, so that boiling points increase or decrease respectively.

- Compressors: this equipment is used to increase the pressure of the working fluid and relies on electricity to do so.

- Heat exchangers: in charge of transferring thermal energy from one medium to another which, in the case of seawater heat pumps, involves heat transfer between the seawater as a heat source and the heat sink. Heat exchange systems for seawater heat pumps in particular, must be made of corrosion-resistant materials. They are also prone to biofouling, so that an electrochlorination system or other alternatives must be put into place.

How do seawater heat pumps work

- The working fluid circulates across the system with a goal: to transfer heat from the source to the sink

- The compressor pressurizes the low-temperature working fluid (at a vapor state) at the evaporator

- It thus moves from a low-temperature side to a high temperature and flows through a condenser

- Heat is extracted in the condenser and change happens from gas to liquid

- A high-pressure fluid now, it goes through an expansion valve that lowers the pressure and temperature

- The working fluid travels back to the evaporator, where the process begins again

Seawater heat pumps increase efficiency: how and why

Seawater heat pumps add to the benefits and extraordinary efficiencies of industrial heat pumps in district heating and cooling networks.

As such, the key advantage is this system’s optimized performance, typically measured by the Coefficient of Performance (COP). This formula measures the amount of electricity needed to generate thermal energy, an area in which seawater heat pumps show outstanding values of between 2 to 6.

This has been proven by both actual operating structures, as well as scientific research. In fact, an experiment published in ‘Utilization of seawater heat pumps in buildings – system energy study of heating & cooling performance’ by Petteri Aalto is especially noteworthy.

After performing a SWHP simulation model based on a Finnish district heating installation using seawater heat pumps, research showed a total heating energy coverage of 77%, and an average COP of between 4.6 and 2.8, depending on the season.

This coincides with figures published by ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), where seasonal COP varied between 2 to 4 for seawater heat pumps.

In other words, seawater heat pumps can facilitate a reliable, extremely efficient installation provided the right design decisions are taken. This, in return, means operators and installations access unparalleled energy sovereignty, decreasing energy dependence from outside sources.

Additionally, as operators look for cost-efficient solutions, district heating employing seawater heat pumps present less operating costs compared to several other district heating options relying on changing energy costs around their power source. In fact, research by Aalto mentioned above calculated this model to become a more profitable investment when looking at reference periods of around 30 years.

The paper also determined the total CO2 emissions of a seawater-based system would be over two times lower compared to a conventional heat pump.

All in all, seawater heat pumps paired with the right district heating structure open the door to build reliable and outstandingly efficient systems that minimize CO2 emissions and generate cost-efficiency in the mid and long term.

Want to learn more about seawater heat pumps and current pioneer structures for efficient and sustainable heating and cooling? At Araner, we’re experts in generating innovative solutions in heating and cooling engineering.

Download our free Heat Pumps Technical Ebook or our free District Heating Ebook and discover some of the current possibilities and state-of-the-art technologies and leading global initiatives.