We frequently use ammonia refrigeration systems for very large cooling applications, such as Industrial Refrigeration. Chillers using ammonia are becoming commonplace in green buildings and may be a viable option for District Cooling systems. As refrigerant legislation continues to get tighter, encouraging the use of alternative environmentally-friendly refrigerants, ammonia becomes a more attractive alternative. Ammonia’s global warming potential and ozone depletion potential are both zero.

What is ammonia?

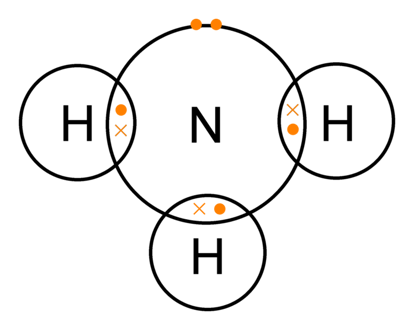

Ammonia, a naturally-occurring gas composed of hydrogen and nitrogen, belongs to a class of refrigerants considered natural refrigerants; which also includes hydrocarbons, water, air, and carbon dioxide. As their name implies, these are naturally-occurring substances capable of refrigeration; they are all environmentally friendly with negligible global warming potential and ozone depletion potential, with ammonia being harmless for the environment. This is especially true when compared to the synthetic refrigerants that have been popular for the last century.

What is ammonia refrigeration system?

Figure 1: The chemical composition of ammonia

Figure 1: The chemical composition of ammonia

Ammonia refrigeration works much like Industrial Refrigeration systems using synthetic refrigerants, with the major exception being that it uses anhydrous ammonia as the refrigerant. Refrigerant grade anhydrous ammonia is a clear, colorless gas or liquid and about 99.95% pure. The purity of the anhydrous ammonia is vital to the properties that make it a good refrigerant. Ammonia was one of the earliest substances used as a refrigerant, replaced by chlorofluorocarbons (CFCs) in the 1920s. In these early days, people thought CFCs were harmless and a great replacement for ammonia with its potential flammability and safety concerns. Now, considering the known environmental concerns with newer refrigerants many are returning to refrigerants like ammonia, which have zero environmental impact. The refrigeration process remains the same regardless of the refrigerant used to transfer heat out of the system.

Liquid anhydrous ammonia intended for refrigeration is stored under pressure, usually in a tank. Release of the pressure on the ammonia results in rapid vaporization. The vaporization process results in cooling much as evaporation of water from a surface do, the temperature drops to the normal boiling point of anhydrous ammonia about -33⁰C. In fact, ammonia’s thermodynamic properties allow it to outperform synthetic refrigerants in most applications.

When to choose ammonia refrigeration systems

Ammonia refrigeration is most commonly used in facilities that have large-scale refrigeration systems such as food and beverage manufacturing facilities, cold storage warehouses, combined cycle power plants, and petrochemical facilities. The cost of ammonia is less than that of more traditional hydrofluorocarbon (HFC) refrigerants, in fact, the cost may be as little as one-tenth.

Ammonia has safety implications which require consideration; it is both a flammable and a health hazard. However, in larger facilities with limited exposure and room for dispersion of the zero environmental impact, natural coolant ammonia can be an ideal choice.

Ammonia refrigeration systems at full capacity are up to 20% more efficient than other systems at full capacity. These systems are substantially more efficient than other chillers are at part capacity. This means that ammonia refrigeration is an excellent choice for plants that are not always running at full capacity.

When to use ammonia refrigeration

Ammonia is utilized in numerous industrial and commercial applications as a refrigerant. Some of its common uses include:

-

Food processing plants: Ammonia is employed in food processing plants for products like meat packing, dairy, fish, fruits, and vegetables. It plays a crucial role in providing cooling for cold storage, freezing, and chilling applications, which helps preserve and extend the shelf life of perishable food items.

-

Cold storage warehouses: Apart from food, these warehouses are used to store pharmaceuticals, chemicals, and other temperature-sensitive products. Ammonia refrigeration is crucial in preventing the spoilage or degradation of these items.

-

Breweries and beverage industry: Ammonia is utilized to cool and maintain the desired temperatures during various processes in breweries, including brewing, fermentation, and storage of beverages.

-

Chemical industry: In the chemical industry, ammonia refrigeration is essential for various processes, reactors, and equipment used in the production, refining, and storage of chemicals.

-

Petrochemical industry: Ammonia is an integral part of operations in the petrochemical industry, where it is employed in processes such as natural gas processing and the cooling of equipment and storage tanks.

Special considerations with the ammonia refrigeration system

Industrial refrigeration systems that use ammonia may require some special planning to help mitigate the potential health and safety hazards. The biggest risk that may occur is an ammonia leak, which is both a health and safety hazard. The most common health concerns with ammonia are skin burns and difficulty breathing, as well as death only in the rarest cases. Leaks most commonly occur during the unloading and loading of ammonia; however, careful and considerate design and diligent training of employees can go a long way towards preventing these leaks.

Many of the materials commonly used in refrigeration systems, copper, for example, are not compatible with ammonia and must be avoided. Ammonia systems require a careful design with a trusted expert like ARANER; using incompatible materials anywhere in the system could cause a potentially deadly leak.

Figure 2: Ammonia warning signs in an industrial refrigeration plant

Figure 2: Ammonia warning signs in an industrial refrigeration plant

It is worth mention that ammonia also has the benefit of typically being able to use smaller refrigerant piping than other refrigerants, so despite requiring specific materials there may be cost savings for the material.

It is also important that the operators have an emergency response plan in place. The operators and all employees working in the ammonia's vicinity need to be familiar with the emergency response plan. The odor threshold for anhydrous ammonia is 5 to 50 parts per million (ppm) and the maximum recommended exposure is 50 ppm over an 8-hour shift; therefore, the basic rule is when you smell ammonia you should back off and test the need for protective equipment such as respirators and suits. In addition, room air is heavier than ammonia therefore the ammonia will rise.

It is also important to consider any local regulations that may exist around the use or storage of ammonia prior to considering ammonia as a refrigerant. Some countries and local jurisdictions have regulations surrounding the safe handling of ammonia.

Is ammonia refrigeration right for your project?

There are many reasons to consider the ammonia refrigeration for your project, chief among them environmental and energy efficiency. Others are turning to ammonia for peace of mind regarding the regulations surrounding synthetic refrigerants, which seem in constant flux. There are other incentives to consider natural refrigerants: for example, in the EU there is a multi-stakeholder initiative called Refrigerants, Naturally! dedicated to helping those with a stake in the retail industry convert to natural refrigerants. This organization and similar ones may help popularize their use and furthering the technology of these natural refrigerants.

The current technology and safety of ammonia refrigeration make it practical for large industrial refrigeration projects. However, thanks to the rising popularity of natural refrigerants, many manufacturers are exploring ways to use ammonia refrigeration safely in mid-size or even smaller applications.

Conclusion

Ammonia has always been a popular choice for Industrial Refrigeration, but now with new regulations and environmental concerns over other refrigerants, there is a renewed focus on ammonia-based systems. If you think ammonia refrigeration might be a fit for your project, contact the professionals at ARANER. We have wide experience with ammonia refrigeration systems, and we can assist you every step of the way from evaluation, to design, to safe operations and maintenance of the completed facility.